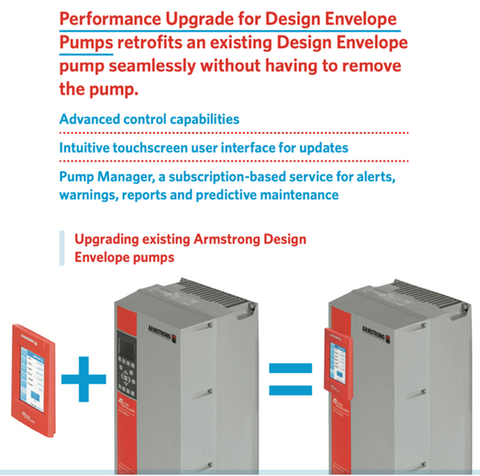

Armstrong’s Design Envelope Controller Upgrade is a one-of-a-kind retrofit solution that replaces the pump's screen while keeping the original pump, motor, drive, and casing in place. The new controller has a simple touchscreen user interface, web server access, BacNet IP protocol compatibility, and a 30-day working history. An inbuilt accelerometer detects vibration in the new Design Envelope Controller. For a limited time, existing Design Envelope pumps may be upgraded with additional control features and connectivity to Pump Manager, an IoT-enabled analytics system, as part of the Performance Upgrade Program. The Performance Upgrade for Design Envelope Pumps program smoothly retrofits an existing Design Envelope pump without the need to remove it, and Armstrong stands behind the belief in life-cycle sustainability.

Pump Manager is a software application that links operators to Design Envelope pumps. It monitors and maintains pump performance in real-time, providing early alerts, web-based trends, and analysis, as well as automated reporting. Design Envelope serves as a safety net for any system modifications that may occur as a result of as-built design, building envelope adjustments, tenant demographic shifts, or changes in building usage. Improved pump speed control is provided by the updated controller, resulting in even higher operational efficiency. Owners of Design Envelope Generation 3.1 pumps with IVS-102 controllers may take advantage of this great offer to gain access to the capabilities and benefits of Armstrong's most revolutionary pump ever. In addition, pump efficiency can be increased by as much as 40% once the new Design Envelope Controller is installed. Design Envelope Controllers and Pump Manager subscriptions are available as a bundle through the Performance Upgrade Program.

The full Performance Upgrade Services Suite can be found through this link.

According to the Armstrong Design Envelope FAQ, “Design Envelope solutions have a larger efficiency range or sweet spot within which they operate effectively. This means that the same equipment will often meet the revised pumping requirements required by a specification change. In addition, Design Envelope solutions exceed today's sustainability requirements meaning that they often meet the requirements of upgrades to building codes. Shifts in HVAC demand due to building design changes can frequently be accommodated with no change to the equipment.”

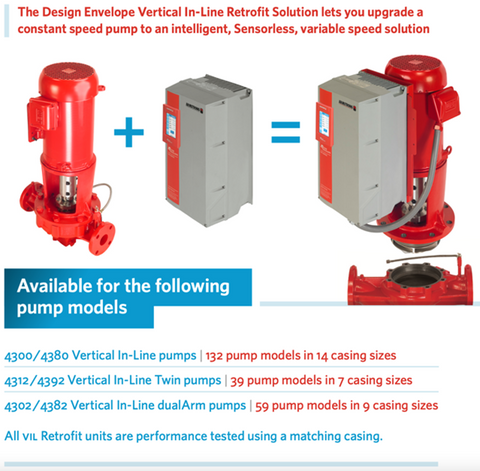

Users can now upgrade existing Vertical In-Line (VIL) constant speed Armstrong pumps with the new Armstrong Design Envelope Vertical-In-Line Retrofit. Simply replace the rotating assembly with a new Design Envelope rotating assembly, including an integrated motor, controller, shaft, impeller, adapter, flush line, seal, and casing gasket. Maintain the existing casing, piping, and pipe insulation while replacing the moving components in their older VIL pumps and updating them to intelligent, variable speed Design Envelope technology. By reusing the casing, you save money on equipment, transportation, and scrap. And because you use existing pipe and insulation, the labor cost is less than half of a completely new variable speed pump, and no pressure test is necessary. Downtime is also decreased. In general, the procedure is less invasive than a full replacement. Compared to a third-party retrofit, the Armstrong technique replaces all moving parts and eliminates the need for sensors, wall-mounted drives, or additional wiring. This program is suitable for users already considering new motors or variable flow, with 5 HP+ constant speed VILs older than five years, notably those between 8 and 20 years.

It is not necessary to replace an older Armstrong S&H circulator with a new one. Instead, an Armstrong Seal Bearing Assembly (SBA) may be used to service it successfully. A pump shaft, sleeve bearing, copper sleeve, and donut wicking system are all replaceable modules in the Armstrong SBA universal seal bearing assembly. More than 100 distinct Armstrong and B&G pump models may be changed to this module program during routine maintenance with as few as five seal-bearing assemblies varieties. Following the conversion, subsequent maintenance usually entails merely the replacement of the module. More information and HVAC tips can be found on HVAC Know It All.

To read Armstrong energy performance upgrade case studies from around the world, click here.

More information on performance upgrades and optimization can also be found on their website.

Shop Armstrong pumps here.