Blower motors are critical for circulating conditioned air throughout a space, which is pivotal in HVAC system operations. By facilitating the flow of fresh air and reducing pollutants, blower motors aid in maintaining high air quality standards.

A Brief History of AC Blower Motors

The rudimentary blower motors of the late 19th and early 20th century were primarily designed for heating, not cooling. Initially, these motors were far less efficient, consuming more power for less output, and were often loud and clunky.

As HVAC systems became more integral to comfort, productivity, and even safety in commercial environments, the demands on blower motors increased significantly. Over the years, technological advancements, fueled by an ever-increasing understanding of aerodynamics, electromagnetism, and materials science, have resulted in a wide range of blower motors designed to suit diverse applications.

The requirements of commercial applications, often much larger and more complex than residential spaces, necessitated motors that were not only more powerful but also more reliable and efficient. For instance, the introduction of Electronically Commutated Motors (ECMs) was largely driven by the need for energy efficiency and cost-effectiveness in commercial settings. These motors offer greater efficiency, quieter operation, and better control over airflow than their predecessors.

Types of Blower Motors

Understanding the different types of blower motors is crucial in comprehending how HVAC systems function in commercial settings. One significant way to classify blower motors is based on their driving mechanism – direct drive, belt drive, or electronically commutated. Each of these blower motor types has unique advantages, and the selection often depends on the specific needs of the commercial space, such as the required airflow, energy efficiency goals, maintenance capabilities, and budget.

Direct Drive Motors

Direct drive motors are highly efficient and reliable as they are directly connected to the fan or blower of the HVAC system. This direct connection reduces the number of mechanical parts in play, minimizing the chances of mechanical failure. These motors also tend to operate quietly and are relatively easy to maintain, making them a popular choice in many commercial HVAC installations.

Belt Drive Motors

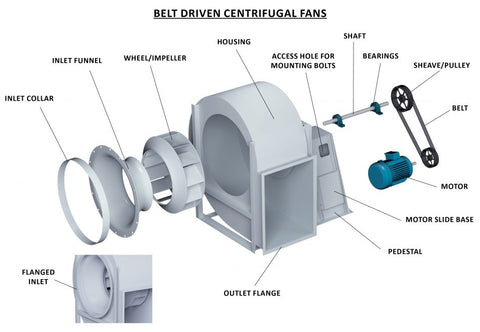

In contrast, belt drive motors operate with a belt-and-pulley system. The motor is connected to the fan or blower through a belt, which transmits power to the fan. This setup offers more flexibility in adjusting airflow rates by altering the pulley sizes. Although belt drive motors can be slightly less efficient due to the potential for belt slippage and require more maintenance, they are beneficial when precise control over airflow is necessary.

ECM (Electronically Commutated Motors)

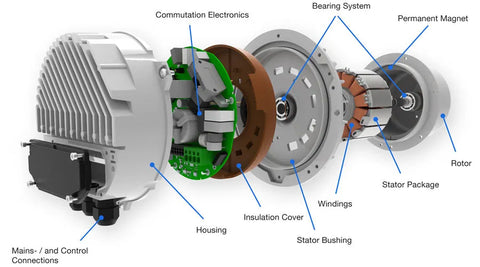

Electronically commutated motors, or ECMs, represent a leap forward in blower motor technology. They use electronic controls to vary speed, offering exceptional efficiency, especially at reduced speeds. ECMs can adapt to the system's changing needs and maintain the desired airflow with less energy consumption. Although they can be more expensive upfront, their energy savings over time often justify the initial investment, making them a preferred choice for many modern commercial HVAC systems.

Read more about ECM blower motors here.

Key Components of an AC Blower Motor

Commercial blower motors consist of several key components that work together to drive the motor and facilitate air circulation throughout the system. When functioning harmoniously, these components ensure the efficient operation of the blower motor.

Rotor

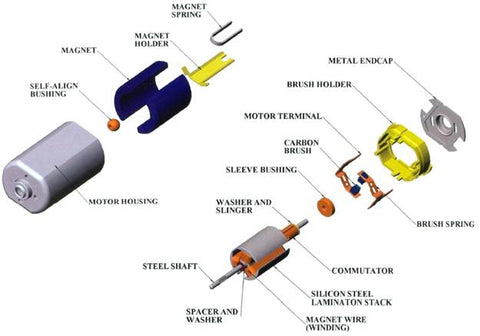

The rotor, also known as the motor core, is the rotating part of the motor. It's typically made of iron or another magnetic material. When an electric current is applied to the windings, it creates a magnetic field that causes the motor core to rotate. This rotation is what drives the fan or blower in the HVAC system.

Windings

The windings, which are coils of wire wrapped around a metal core, are another crucial component. When electricity is passed through these windings, they generate a magnetic field that interacts with the motor core to create rotational motion. Depending on the design of the motor, these windings can be found on either the rotor (for squirrel-cage induction motors) or the stator (the stationary part of the motor).

Bearings

Bearings are essential for the smooth and efficient operation of a motor. These components support the motor shaft and allow it to rotate freely with minimal friction. Bearings must be regularly lubricated to prevent wear and tear and ensure the motor runs smoothly. Failure of the bearings can lead to a noisy motor and, eventually, motor failure.

Drive Shafts

The drive shaft, also known as the motor shaft, is the part of the motor that transfers the rotational motion from the motor to the fan or blower. It's typically made of sturdy, corrosion-resistant materials to withstand the stresses of operation.

Understanding Motor Specifications

Understanding motor specifications is vital to selecting and maintaining a commercial HVAC blower motor. These specifications provide essential information about the motor's performance, power, and efficiency.

Horsepower

Horsepower is a unit of power that indicates the strength of a motor. It signifies the motor's capacity to perform work over time. In an HVAC context, the motor's horsepower will influence the system's ability to condition air and circulate it effectively throughout a commercial space. Higher horsepower motors are typically used in larger systems or settings requiring significant airflow.

RPM (Revolutions Per Minute)

RPM, or Revolutions Per Minute, measures the speed at which the motor shaft is rotating. This is an important specification as the speed of the motor directly affects the speed of the blower or fan and, thus, the airflow rate of the HVAC system. Motors with variable speed capabilities can adjust their RPM to provide optimal airflow under different conditions.

Voltage & Amperage

Voltage and amperage are electrical specifications that are essential for safe and efficient operation. Voltage is the force of the electrical current, while amperage is the volume of the electrical current. In essence, voltage is how hard the electricity is being pushed, and amperage is how much electricity is flowing. These specifications ensure the motor is compatible with the building's electrical supply.

Motor Efficiency

Motor efficiency is a measure of how much of the electrical energy input to the motor is converted into mechanical energy, often expressed as a percentage. Higher efficiency motors convert a greater proportion of their electrical input into useful work, wasting less energy as heat, noise, or vibration. With the rising costs of energy and increased focus on sustainability, motor efficiency has become an increasingly important specification.

How Blower Motors Work in HVAC Systems

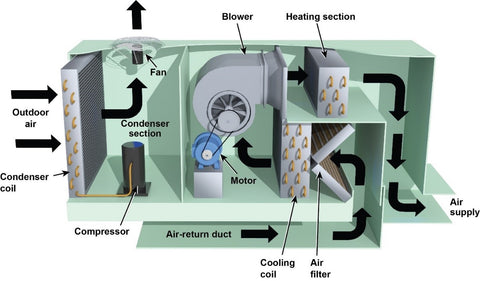

A blower motor serves as the heart of an HVAC system, driving the movement of air through various stages of heating or cooling. When the thermostat in a building calls for a temperature change, this signal activates the blower motor via the control board in the HVAC system.

Powered by electricity, the motor starts to rotate. Its rotation speed depends on the type of motor and the specific settings configured in the system. A key component linked to the motor shaft is the blower wheel, also known as the fan, which moves in sync with the motor.

As the blower wheel rotates, it draws air from the return ducts throughout the building. This air, typically at room temperature, is then ushered over the system's heating element or cooling coil, where it gets heated or cooled based on the activated mode.

Post conditioning, the blower wheel propels the air into the supply ductwork. From here, the treated air travels to different areas of the building, thereby maintaining the desired temperature. This cycle continues for as long as the thermostat demands heating or cooling.

In systems equipped with variable-speed blower motors, the rotation speed of the motor can be adjusted. This flexibility allows the system to control the volume of airflow accurately in response to the specific heating and cooling requirements at any given moment.

Read more about Blower Fans.

Selecting the Right Blower Motor for Your Commercial HVAC System

Selecting the suitable blower motor for your commercial HVAC system is vital in ensuring optimal system performance and energy efficiency. A few key factors should be considered during this selection process.

Sizing considerations are crucial. The size of the blower motor should align with the needs of your HVAC system and the size of the space it serves. A too-small motor may not provide sufficient airflow for proper temperature regulation, while an overly large one may result in unnecessary energy usage and wear on the system. Sizing involves assessing the heating and cooling demands of the space and ensuring the motor's capacity aligns with these needs.

The motor's energy efficiency ratings > can significantly impact the overall operational cost of the system. Motors with higher efficiency ratings, such as ECMs, consume less energy to deliver the same output as less efficient models. While these motors may have a higher upfront cost, they can offer substantial savings in the long run through reduced energy consumption.

Load requirements > refer to the demands placed on the motor during operation. These can vary based on factors such as the size of the commercial space, the number of occupants, and any unique environmental needs, like stringent temperature control or air filtration. Understanding these requirements can help you select a motor that reliably meets these needs without overloading.

Environmental conditions are another important factor to consider. If the HVAC system operates in high temperatures, high humidity, or exposure to certain chemicals, you'll need a motor designed to withstand these conditions. Moreover, in situations with specific noise restrictions, selecting a quieter motor type, like an ECM, may be beneficial.

Considering these factors and consulting with a knowledgeable HVAC professional can help ensure you select the right blower motor for your commercial HVAC system, balancing immediate costs with long-term energy efficiency and system performance.

Common Problems with Blower Motors

Blower motors can sometimes run into problems that affect their performance and the system's overall functioning. Recognizing common issues can help in diagnosing problems and implementing timely solutions.

Motor Failure

Motor failure is one of the most severe problems with an AC blower motor. Failure could be due to various reasons, including worn-out bearings, electrical faults, or overheating. Regular maintenance can help prevent such failures by ensuring all components are in good working condition and addressing any potential issues early.

Overheating

Overheating is another common issue with HVAC blower motors. Over time dust and debris can accumulate on the motor, impeding its ability to dissipate heat. Moreover, a motor operating under too heavy a load, or one not correctly sized for the system, can also overheat. This can cause the motor to shut down to prevent damage, affecting the system's ability to heat or cool the space.

Noise Issues

Noise issues can be a sign of a problem with the blower motor. Unusual noises like grinding, screeching, or rattling could indicate problems like loose parts, worn-out bearings, or issues with the belt (in belt-driven systems). Noise issues should be addressed promptly to prevent further damage to the motor or other components of the HVAC system.

Electrical Problems

Electrical problems, including wiring issues or faults with the motor's electrical components, can also affect the performance of the blower motor. For instance, issues like short circuits or loose connections can cause the motor to operate intermittently or not at all. Regular inspections and proper installation can help prevent many such electrical problems.

Weak or No Air Flow

Weak or no airflow is a common issue that can occur, and it often points toward problems with the blower motor or related components. When the system exhibits weak airflow, it usually indicates that the blower motor is not operating at full capacity. This could be due to a variety of reasons, including a motor that's underpowered for the size of the system, issues with the motor's electrical supply, or mechanical problems like worn-out bearings or a damaged fan belt.

On the other hand, no airflow usually suggests a more severe problem with the blower motor. The motor might have failed completely due to an electrical fault, overheating, or severe mechanical damage. Alternatively, the issue could be with the fan or blower—the component that the motor drives to move air through the system. If the fan or blower is damaged or blocked, it could prevent air movement even if the motor works.

It's important to note that problems with other parts of the HVAC system can also cause weak or no airflow. For instance, blocked or leaking ductwork can prevent the effective distribution of conditioned air, and issues with the HVAC controls or thermostat can lead to improper operation of the blower motor.

Maintenance & Troubleshooting Tips

Proper maintenance and timely troubleshooting are vital to ensuring the longevity and efficient operation of the blower motor in a commercial HVAC system.

Regular maintenance is essential to keep the blower motor in good working condition. This includes cleaning the motor and its surrounding area to prevent dust accumulation, lubricating the bearings (if applicable), checking the electrical connections for any signs of wear or damage, and inspecting the fan or blower for any issues. Regularly replacing the air filters in the HVAC system can also help reduce the load on the motor and prevent overheating.

Recognizing signs of potential problems can help catch issues early and prevent major breakdowns. These signs may include unusual noises from the motor, weak or no airflow from the HVAC system, unexplained rises in energy consumption, or the HVAC system failing to maintain the desired temperature. Any of these signs should trigger a closer inspection of the system.

Troubleshooting steps can help identify the cause of any problems. For instance, if the motor is not running, you can check the electrical connections and the power supply. If the airflow is weak, inspect the fan or blower for any blockages or damage. If the motor is making noise, check for worn-out bearings or issues with the fan belt (in belt-driven systems).

Blower Motor FAQs

What is the lifespan of a commercial blower motor?

The lifespan of a blower motor can vary significantly based on several factors, including the type of motor, the operating conditions, and how well it's maintained.

Typically, a commercial blower motor lasts 10 to 20 years. However, this is a general estimate, and the actual lifespan can be shorter or longer. For instance, motors that operate under harsh conditions, such as high temperatures, high humidity, or heavy dust, may experience a shortened lifespan due to increased wear and tear.

The type of motor can also affect its lifespan. For example, ECMs are more energy-efficient and tend to have a longer lifespan than traditional motors because they run cooler and have fewer mechanical parts that can wear out.

How can I tell if my HVAC blower motor is failing?

Recognizing the signs of a failing HVAC (Heating, Ventilation, and Air Conditioning) blower motor is crucial to preventing a complete system breakdown. Here are some indicators that your blower motor may be on its way out:

- Unusual noises: One of the first signs you might notice is a change in the sounds your system makes. If your blower motor is beginning to fail, it might make unusual noises such as humming, screeching, rattling, or grinding. These sounds could indicate a variety of issues, such as worn-out bearings, a problem with the belt, or an electrical issue within the motor.

- Reduced airflow: If your HVAC system is not pushing out as much air as it usually does, it could be a sign of a problem with the blower motor. A weakening motor may be unable to spin the fan blades with as much force, leading to a decrease in airflow. However, it's important to note that other issues, such as dirty air filters or problems with the ductwork, can also cause reduced airflow.

- The system struggles to maintain the set temperature: If your HVAC system has difficulty maintaining the temperature you've set on your thermostat, it could be due to a failing blower motor. If the motor can't generate enough airflow, the system will struggle to heat or cool your space effectively.

- The motor doesn't start: If the motor doesn't start at all, it could be a sign of a serious problem. This could be due to an electrical issue, such as a blown fuse or a problem with the wiring, or it could mean that the motor itself has failed.

- Unexplained rise in energy bills: A failing blower motor may have to work harder to produce the same amount of airflow, resulting in higher energy consumption. Check your blower motor if you notice a sudden or unexplained increase in your energy bills.

If you notice any of these signs, it's important to have your HVAC system inspected by a professional. Promptly addressing any issues can help prevent a small problem from turning into a costly repair or replacement.

How often should a commercial HVAC blower motor be serviced?

The frequency at which a blower motor should be serviced depends on several factors, including the type of the system, the environment in which it operates, and how heavily it's used.

Generally, most commercial HVAC systems should be inspected and serviced at least twice a year – typically in the spring and fall. These inspections should include a check of the blower motor to ensure it's operating correctly and efficiently. These semi-annual maintenance visits are designed to prepare the system for the heavy load of summer and winter months and can help prevent unexpected breakdowns during these peak seasons. More frequent servicing may be needed for environments that are particularly harsh or dusty or for systems that are used very heavily.

Can a faulty blower motor increase my energy costs?

Yes, a faulty blower motor can indeed increase your energy costs. The blower motor plays a vital role in your HVAC system by circulating air throughout your building. When it's not working efficiently, the entire system has to work harder to maintain the desired temperature, leading to increased energy consumption.

If the blower motor struggles to push air due to a mechanical problem or blockage, other parts of the HVAC system, such as the compressor, might have to work harder to compensate, potentially using more energy.

A faulty blower motor might cause the system to start and stop more frequently, a cycle known as short cycling. This is one of the most energy-intensive operations for an HVAC system, as starting the system uses more energy than simply running it.

What is the difference between a direct drive and a belt drive motor?

Direct drive and belt drive are different configurations for attaching the blower or fan to the motor. Each has its advantages and disadvantages and is suitable for different applications.

In a direct drive configuration, the blower or fan is directly attached to the motor's shaft, meaning that the motor and blower rotate at the same speed. Because there are fewer moving parts, direct drive systems are generally more efficient, require less maintenance, and are quieter than belt drive systems. They are typically used in applications where space is limited because the direct drive setup is more compact.

However, the speed of direct drive motors is more difficult to adjust compared to belt drive motors. Although variable speed motors can provide some flexibility, they cannot match the wide range of speed adjustment belt drive systems offer.

In a belt drive configuration, the motor is connected to the blower or fan via a belt and pulley system. This arrangement allows for flexibility in the speed of the blower, as changing the size of the pulleys can alter the speed ratio between the motor and the blower.

Belt drive systems are generally used in larger HVAC systems where there's more space and where adjustable airflow is needed. However, they require more maintenance than direct drive systems because the belt can wear out, lose tension, or break, and the pulleys can become misaligned. Belt drive systems can also be noisier and less efficient than direct drive systems because of the additional moving parts.

Blower Motors by Manufacturer

Carrier Blower Motors

Carrier blower motors deliver powerful and consistent airflow in HVAC systems. These motors drive the fans that circulate air throughout the system, ensuring efficient air movement and comfortable indoor conditions.

Trane Blower Motors

Trane blower motors provide the necessary airflow in HVAC systems by driving the fans that circulate air throughout the system, ensuring efficient air movement.

Daikin Blower Motors

Daikin blower motors are specifically engineered to provide powerful and reliable airflow in HVAC systems. These motors are vital in driving the fans that circulate air throughout the system, ensuring efficient air movement and maintaining comfortable indoor environments.

York Blower Motors

Built for reliable operation, York blower motors provide optimal performance, ensuring the smooth running of the cooling and heating systems, contributing to a comfortable indoor environment.

Lennox Blower Motors

Lennox blower motors ensure efficient airflow through the HVAC units. They are engineered to provide dependable service, enabling the system's cooling and heating mechanisms to work effectively, thus providing a comfortable living or workspace.

AAON Blower Motors

AAON blower motors drive the air circulation in HVAC systems. Manufactured for resilient and steady performance, these motors ensure the effective operation of heating and cooling processes, thus aiding in maintaining the comfort level of indoor spaces.

Johnson Controls Blower Motors

Responsible for moving air across the system's condenser and evaporator coils, Johnson Controls blower motors are designed for efficiency and longevity. Their performance directly affects the overall heating and cooling process, helping maintain the desired indoor comfort levels.