What is a Commercial A/C Compressor?

A commercial A/C (air conditioning) compressor is a key component of an air conditioning system, primarily found in commercial buildings such as offices, retail spaces, restaurants, hotels, and other large-scale facilities. Its primary function is to compress the refrigerant gas, raising its temperature and pressure before it is sent through the condenser coil to release its heat and convert it into a liquid state.

The compressor effectively plays the role of the heart in the air conditioning system, pumping refrigerant through the system. A motor powers it and has two sides: a suction side, where the refrigerant gas enters from the evaporator, and a discharge side, where the compressed, hot refrigerant gas exits and moves towards the condenser.

Commercial A/C compressors are typically more powerful than residential ones, as they're required to cool larger spaces. They come in various types, including reciprocating, screw, scroll, and centrifugal compressors, each offering different efficiencies, costs, and suitable applications. The performance and efficiency of a commercial A/C compressor can significantly impact the energy use and operating costs of a building.

How do A/C Compressors Work?

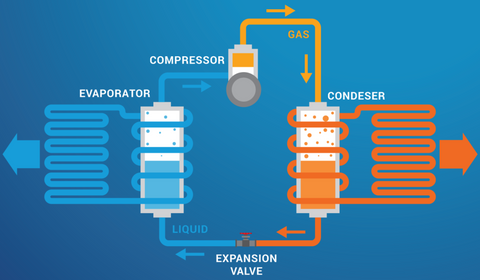

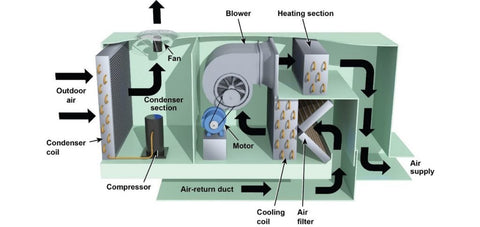

Commercial air conditioning (A/C) compressors work as part of a larger HVAC (Heating, Ventilation, and Air Conditioning) system to cool and maintain comfortable conditions in commercial spaces. The process involves a continuous cycle of refrigerant gas conversion, which consists of four primary stages: evaporation, compression, condensation, and expansion:

- Evaporation: In this stage, the refrigerant enters the evaporator coil as a low-pressure liquid. As indoor air is blown over the evaporator coils, the refrigerant absorbs heat from the air and evaporates into a gas. This cooled air is then distributed throughout the building.

- Compression: The now low-pressure refrigerant gas is drawn into the compressor, which is typically located in the system's outdoor unit. The compressor's function is to pressurize this gas, which increases its temperature significantly – this process transforms the refrigerant into a high-pressure, high-temperature gas.

- Condensation: This hot, high-pressure refrigerant gas then flows into the condenser coils. As outdoor air is blown over these coils, the refrigerant releases heat to the outside and cools down, condensing back into a high-pressure liquid.

- Expansion: The high-pressure liquid refrigerant then moves through the expansion valve, where its pressure is abruptly decreased. This process causes the refrigerant to cool significantly, becoming a low-pressure liquid. This liquid then enters the evaporator coil, and the cycle repeats.

The A/C compressor is the heart of this process, propelling the refrigerant through each stage. Without the compressor, the refrigerant would not move through the system, and the heat transfer process necessary for cooling the building would not occur.

Types of A/C Compressors

Commercial air conditioning (A/C) systems can utilize several types of compressors, each with different characteristics, efficiencies, and costs. These are some of the most common types of commercial A/C compressors:

Reciprocating Compressors

Also known as piston compressors, these are similar to a car engine's piston and cylinder system. They draw the refrigerant into a cylinder through a suction valve, then a piston compresses the refrigerant, and it's discharged through an exhaust valve. They are often used in small to medium-sized commercial HVAC systems as they are durable and cost-effective.

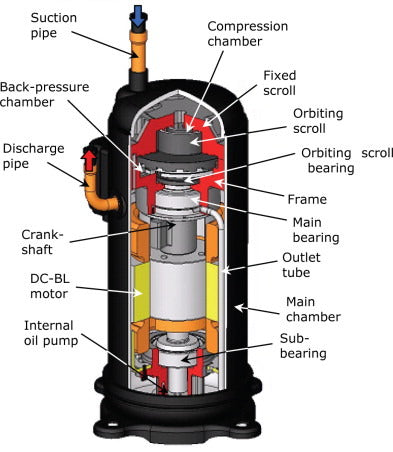

Scroll Compressors

Scroll compressors feature two spiral-shaped scroll components. One scroll remains stationary while the other orbits around it, compressing the refrigerant. Scroll compressors are known for their efficiency, reliability, and quiet operation. They are widely used in a variety of applications, from small to large commercial HVAC systems.

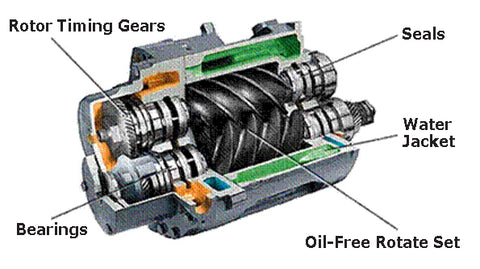

Rotary Screw Compressors

These compressors consist of two large helical rotors that compress the refrigerant as they turn in opposite directions. They are known for their durability and efficiency and are typically used in large commercial or industrial HVAC systems that require continuous operation and high capacity.

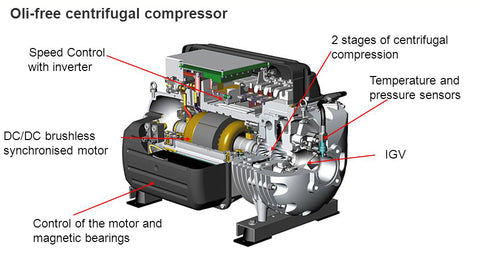

Centrifugal Compressors

Centrifugal compressors use a rotating impeller (a kind of rotor) to accelerate the refrigerant, then decelerate it through a diffuser, resulting in increased pressure. They are most effective at high cooling capacities and are ideal for large commercial applications like skyscrapers or industrial processes. Centrifugal compressors are appreciated for their large-scale efficiency, but they can be costly and complex to maintain.

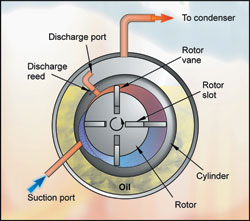

Rotary Vane Compressors

These compressors have a rotor with several blades inserted in radial slots that compress the refrigerant as the rotor turns. They are compact and can provide high sustained air pressure, making them suitable for smaller commercial applications.

Each type of compressor has its advantages and disadvantages, and the choice between them depends on various factors, including the scale of the system, the cooling load, efficiency requirements, noise considerations, and budget.

How to Choose an A/C Compressor

Choosing a commercial air conditioning (A/C) compressor requires careful consideration of several factors, as it's a vital component that significantly impacts the HVAC system's performance, efficiency, and operating costs. Here are some key factors you should consider:

- Size & Cooling Capacity: The compressor must cool the intended space efficiently. Too small, and it won't cool the space adequately; too large, and it will cool too quickly, leading to frequent on/off cycling, which can wear out the system and lead to uneven cooling. An HVAC professional can perform a load calculation to determine the correct size.

- Type of Compressor: As mentioned earlier, there are various types of compressors – reciprocating, scroll, rotary screw, centrifugal, and rotary vane. Each type has its strengths and weaknesses and is suited to different applications. For example, a scroll compressor might be a good fit for a medium-sized office building due to its efficiency and quiet operation. In contrast, a centrifugal compressor might be best for a large skyscraper.

- Efficiency: Higher efficiency units can result in significant energy savings over the system's life, even though they might cost more upfront. The Seasonal Energy Efficiency Ratio (SEER) is commonly used to rate the efficiency of an A/C system – a higher SEER rating means greater efficiency.

- Durability & Maintenance: Some compressors are more durable and require less maintenance. However, regular professional maintenance is essential to keep any compressor running effectively and to prolong its lifespan.

- Noise Level: Noise can be a concern, particularly in certain environments. Some compressors, such as scroll compressors, operate more quietly than others.

- Cost: Budget is always a consideration. This includes not only the upfront cost of the compressor but also the cost of installation, maintenance, and operation over its lifetime. An efficient, high-quality compressor may cost more initially but save money in the long run by reducing energy costs and lasting longer.

- Compatibility: The compressor should be compatible with the rest of the HVAC system, including the type of refrigerant used.

- Regulations & Standards: Ensure the compressor meets all applicable regulations and standards in your region, including environmental and energy-efficiency standards.

Generally, it's best to consult a qualified HVAC professional to help choose the suitable compressor for your commercial A/C system. They can consider all these factors and make a recommendation based on your specific needs and circumstances.

A/C Compressor Installation Considerations

Installing a commercial air conditioning (A/C) compressor requires meticulous planning and execution, considering various factors influencing its performance, longevity, and operational efficiency. Here are some key considerations:

- Location: As part of an outdoor unit, the compressor should be installed in a location that's easily accessible for maintenance and repair but also away from high-traffic areas to minimize noise disturbance. It should also be placed in a well-ventilated area and away from direct sunlight, if possible, to prevent overheating.

- Proper Sizing: As mentioned earlier, the compressor's size and cooling capacity should match the building's cooling load. A compressor that's too small or too large can lead to inefficiency, higher energy costs, and shorter equipment lifespan.

- Professional Installation: Commercial A/C compressors are complex and require professional installation to ensure they're installed correctly and safely, comply with all relevant regulations and codes, and operate efficiently.

- Ductwork & Insulation: The ductwork should be well-designed and properly installed to ensure efficient distribution of cooled air. Insulation is also crucial to prevent energy loss.

- Electrical Requirements: The compressor should have a dedicated electrical circuit to handle its power needs, and all electrical work must comply with local codes and standards.

- Refrigerant Charge: The compressor should be correctly charged with the appropriate type and amount of refrigerant. An incorrect refrigerant charge can lead to inefficient operation and potential damage to the compressor.

- System Compatibility: The compressor should be compatible with the other HVAC system components. Compatibility issues can lead to decreased performance and potential system damage.

- Climate Considerations: The type of compressor and its installation may need to be adapted based on the local climate, particularly if the system will be used for both cooling and heating.

- Noise & Vibration Damping: Consider measures to minimize noise and vibration, such as installing the unit on a solid, level surface and using noise-damping mounts or enclosures.

- Routine Maintenance Plan: Regular maintenance is crucial to keep the compressor and the entire HVAC system working efficiently and reliably. Have a plan in place for routine professional inspections and maintenance.

Compressors by Manufacturer

Carrier Compressors

Carrier is a globally recognized brand, well-known for manufacturing a wide range of HVAC equipment, including commercial air conditioning (A/C) compressors. Their commercial A/C compressors are designed to deliver reliable and efficient cooling for a variety of large-scale applications such as office buildings, hotels, and retail spaces. Built to withstand demanding conditions, Carrier's compressors boast durability, high performance, and energy efficiency. They offer different types of compressors, including scroll, screw, and centrifugal, to meet diverse cooling requirements and capacities. As a leader in the industry, Carrier is committed to sustainability and innovation, continuously striving to improve energy efficiency and reduce environmental impact, all while ensuring optimal comfort and air quality.

Trane Compressors

Trane offers a comprehensive line of commercial air conditioning compressors renowned for their quality, dependability, and high efficiency. Catering to a broad spectrum of commercial needs, Trane's compressors are engineered with advanced technology that ensures optimal performance across various applications, from retail stores and office buildings to larger facilities like hotels and hospitals. Available in an assortment of types, including scroll, centrifugal, and screw, Trane's compressors are versatile to handle different cooling capacities.

Daikin Compressors

Daikin, a globally leading manufacturer in the HVAC industry, provides a diverse range of commercial air conditioning compressors known for their technological innovation, energy efficiency, and reliability. Daikin's compressors, including scroll, screw, and centrifugal types, serve a wide range of commercial settings, from small businesses to expansive industrial facilities. Integrating advanced features, these compressors deliver superior performance, precise temperature control, and enhanced comfort.

York Compressors

York offers an array of commercial air conditioning compressors that combine durability, technological advancement, and environmental responsibility. Suitable for a myriad of commercial applications, York's compressors come in various types, including scroll, screw, and centrifugal, ensuring versatile solutions for diverse cooling needs. These compressors are constructed to deliver exceptional cooling performance, precise climate control, and long-lasting operation.

Johnson Controls Compressors

Johnson Controls manufactures a comprehensive line of commercial air conditioning compressors highlighting innovative design, resilience, and commitment to environmental sustainability. The compressors, available in diverse types such as scroll, screw, and centrifugal, are engineered to meet the multifaceted cooling demands of various commercial spaces. These units are characterized by their sturdy build, top-notch cooling performance, and precise indoor climate regulation.

Shop Johnson Controls Compressors

Lennox Compressors

Lennox produces an extensive selection of commercial air conditioning compressors that prioritize dependable performance, advanced technology, and sustainability. These compressors, available in types such as scroll, screw, and centrifugal, are tailored to fulfill the cooling requirements of various commercial environments. They're recognized for their robust construction, efficient cooling capabilities, and precise temperature management.

AAON Compressors

AAON offers an array of commercial air conditioning compressors marked by innovation, resilience, and environmental mindfulness. Available in various types, such as scroll, screw, and centrifugal, these compressors cater to diverse cooling demands in a range of commercial settings. Renowned for their robust construction, superior cooling efficacy, and precise temperature regulation, AAON's compressors ensure optimal indoor climate control.