ASCO offers a comprehensive range of solenoid valves tailored for diverse applications, ensuring precision, reliability, and efficiency across multiple industries.

What is a Solenoid Valve?

A solenoid valve is an electromechanical device that controls the flow of liquids or gases. At its core, the valve operates using an electromagnetic solenoid: when an electric current is passed through a coil (the solenoid), it generates a magnetic field that moves a plunger inside the valve. This movement either opens or closes the valve, allowing or stopping the flow of the medium (liquid or gas).

The primary advantage of a solenoid valve is its ability to offer rapid and precise control remotely. Since its actuation is based on the presence or absence of an electric current, it can be easily integrated into automated systems. Solenoid valves are used in a wide range of applications, from simple household water systems to complex industrial automation processes. They come in various configurations, including direct-acting, pilot-operated, and others, to cater to specific requirements of pressure, flow rate, and application.

How Does a Solenoid Valve Work?

A solenoid valve operates based on the principles of electromagnetism, with its core components being a coil of wire and a movable plunger made of ferromagnetic material. When an electric current is passed through the coil, it generates a magnetic field, which attracts the plunger, causing it to move within the coil.

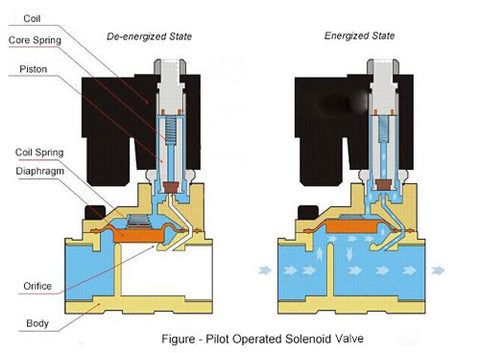

In direct-acting valves, this plunger movement directly opens or closes the valve orifice. When the coil is energized, the magnetic field prompts the plunger to change the valve's position, typically reverted to its original state by a spring once the coil is de-energized. However, in pilot-operated valves, the plunger controls a smaller pilot orifice, leading to a change in pressure. This pressure difference then acts on a diaphragm or piston, which controls the main valve orifice. These types of valves are particularly beneficial for handling larger flows or higher pressures.

Some solenoid valves, known as "latching solenoids," have a bistable mechanism, enabling the valve to remain in its last commanded position even after the electric current is turned off. Through the precise control of the plunger's position via the magnetic field, solenoid valves effectively regulate the flow of liquids or gases, making them invaluable in various applications requiring swift and reliable flow adjustments.

This video from the Engineering Mindset explains the basic actuator control valve working principle:

Different Types of Solenoid Valves

Solenoid valves come in a variety of types, each designed to cater to specific applications and operational requirements. Different types of solenoid valves can also be characterized by the media they control (air, water, oil, etc.), the materials they're made of, their operating pressure range, and their voltage requirements. The choice of solenoid valve type largely depends on the specific application, flow requirements, and operational conditions.

Direct-Acting Solenoid Valves

A direct-acting solenoid valve features the solenoid directly interacting with the valve's main sealing mechanism, often a diaphragm or a plunger. When the solenoid coil is activated, it creates a magnetic field that directly moves this sealing mechanism, resulting in the valve either opening or closing. The immediate connection between the solenoid and the sealing element allows the valve to respond quickly and reliably. One notable advantage of direct-acting solenoid valves is their capability to function even at zero differential pressure, making them versatile for various applications. They're particularly suited for environments that demand swift reactions or use in low-pressure or vacuum systems. However, their design can limit their size, potentially making them less ideal for scenarios requiring high flow rates or larger piping.

Pilot-Operated Solenoid Valves

A pilot-operated solenoid valve operates somewhat differently than its direct-acting counterpart. In a pilot-operated solenoid valve, the solenoid doesn't directly control the main valve's flow. Instead, it manages a smaller pilot valve that, when actuated, influences the flow of media, which in turn controls the operation of the main valve. When the solenoid is energized, it opens the pilot valve, allowing the media (often the same fluid that's controlled by the main valve) to either pressurize or relieve pressure from a diaphragm or piston mechanism. This change in pressure causes the main valve to open or close. Pilot-operated solenoid valves are often favored for applications with higher flow rates or larger pipe diameters. However, they typically require a minimum pressure differential across the valve to function effectively, meaning they might not operate correctly in systems with very low or zero differential pressure. The added complexity of the pilot mechanism often provides the benefit of allowing a relatively small solenoid to control a much larger flow, leveraging the media's pressure to actuate the main valve.

2-Way Solenoid Valves

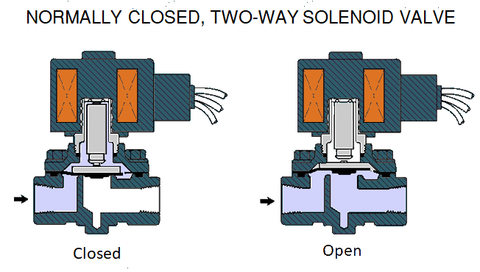

A 2-way solenoid valve has two ports: an inlet and an outlet. The solenoid's function in this setup is to either allow or prevent the flow of media (such as gas or liquid) between these two ports. When the solenoid coil is energized, the valve may open or close, depending on its default state. If it's a normally closed valve, energizing the coil will open it, allowing flow; conversely, if it's a normally open valve, energizing the coil will close it, stopping the flow. The simplicity of 2-way solenoid valves makes them widely used in numerous applications where straightforward on/off control of the flow is required.

3-Way Solenoid Valves

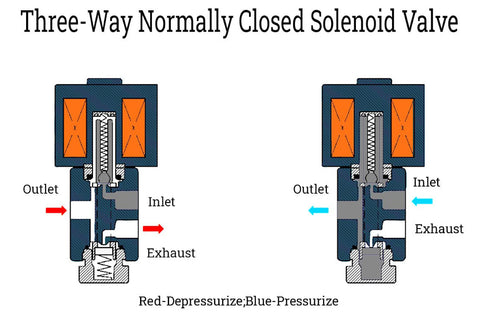

A 3-way solenoid valve features three ports and can control the flow between these ports in various configurations. It is designed to manage two distinct paths for the media to flow, often referred to as the "normally open," "common," and "normally closed" paths. When the solenoid is energized, it can either redirect the flow from one path to another or block one of the paths entirely. Such valves are commonly used in applications where fluid direction needs to be alternated or where a specific function like mixing or diverting is required. For instance, a 3-way solenoid valve might be employed to switch between fluid sources or to control the output between two different lines.

4-Way Solenoid Valves

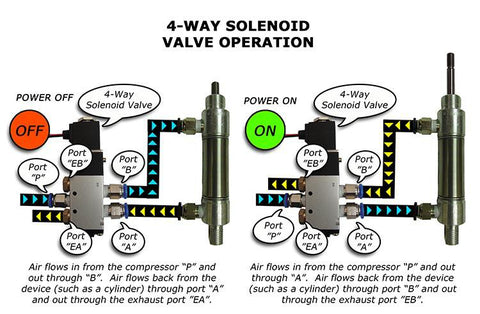

A four-way solenoid valve has four distinct ports, typically used to control double-acting actuators, like some pneumatic cylinders. With this design, the valve can direct airflow (or another medium) from a single source to one of two outputs while simultaneously providing an exhaust path for the displaced air from the opposite end of the actuator. When the solenoid is energized, it changes the flow path, reversing the direction of movement in the actuator. Essentially, a 4-way solenoid valve can control the extension and retraction of a double-acting actuator by switching the flow direction. This capability makes it especially valuable in automation systems, where precise control over actuator movement is essential.

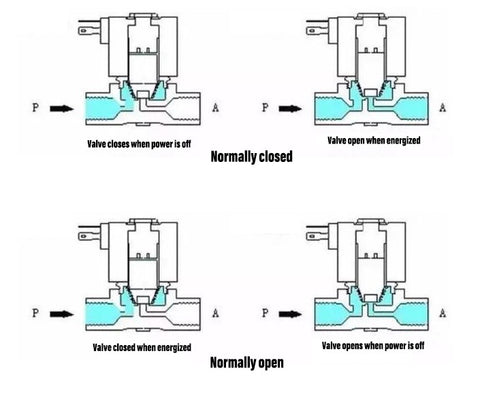

Normally Closed (NC) Valves

The valve remains in the closed position in normally closed solenoid valves when the solenoid is de-energized or not powered. In this state, the flow of media through the valve is blocked. When the solenoid coil is energized or activated by an electrical current, the valve opens, allowing the flow of media. Once the electrical power is removed or turned off, the valve returns to its default closed position, typically due to a spring or other restoring force. This type of valve is commonly used in applications where the flow must be stopped by default for safety or operational reasons, and the flow is only allowed under specific conditions or when prompted by a control signal.

Normally Open (NO) Valves

A normally open solenoid valve is designed so that the valve remains in the open position when the solenoid is de-energized or not powered. This means that, in its default state, the flow of media through the valve is allowed. However, when the solenoid coil is energized or activated by an electrical current, the valve transitions to the closed position, blocking the flow of media. After the electrical power is removed or turned off, the valve reverts to its default open position, usually due to a spring or other restoring force. This kind of valve is often employed in scenarios where flow should predominantly remain unobstructed and only be interrupted or stopped under certain conditions or in response to a specific control signal.

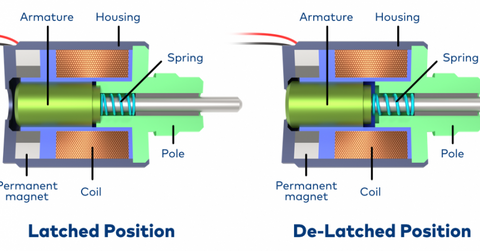

Latching Solenoid Valves

A latching solenoid valve utilizes a mechanism to maintain its current state, either open or closed, without the continuous need for electrical power. Once a brief electrical pulse actuates the solenoid, it "latches" into its new position, either open or closed. To change the valve's state again, another electrical pulse is applied, typically of reversed polarity. The primary advantage of a latching solenoid valve is its energy efficiency, as it doesn't require a continuous power supply to maintain its position. This feature makes it especially useful in battery-operated applications or scenarios where power conservation is crucial. The valve relies on permanent magnets or a bistable mechanism to achieve this latching capability, which ensures it remains in its last position until it receives another actuation signal.

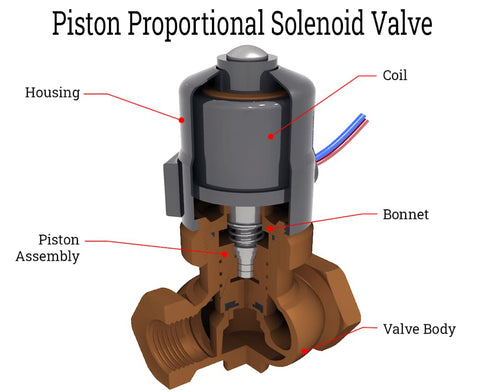

Proportional Solenoid Valves

A proportional solenoid valve differs from traditional on/off solenoid valves by offering variable control over the flow rate of the media passing through it. Instead of just an open or closed position, a proportional solenoid valve adjusts its opening in response to the amount of electrical current applied to its solenoid coil. The more electricity applied, the wider the valve opens, and vice versa. This allows for precise control of flow rates, pressures, or temperatures. The valve's ability to provide a range of flow rates based on the input signal makes it ideal for applications that require more nuanced and controlled responses rather than just a simple on/off function.

Isolation Solenoid Valves

An isolation solenoid valve isolates the fluid being controlled from the valve's actuation components. This means that the medium passing through the valve doesn't come into direct contact with the solenoid or other operational elements of the valve. Typically, the valve employs a diaphragm or a sealed barrier to achieve this isolation. The primary purpose of an isolation valve is to prevent contamination or corrosion that could be caused by the fluid interacting with the valve's moving parts or the solenoid itself. This design is especially crucial for applications dealing with aggressive, corrosive, or high-purity fluids.

About ASCO

Founded in 1888 in Baltimore, Maryland, ASCO, short for the Automatic Switch Company, initially specialized in elevator, compressor, and generator controls. However, the company soon pivoted its focus to solenoid valves, introducing the world's first solenoid valve in the 1910s, a groundbreaking development in fluid control. This innovation positioned ASCO as a forerunner in solenoid valve technology. As the years progressed, their dedication to innovation and quality made them a preferred choice across various sectors, from medical to energy. In 1985, their acquisition by global technology giant Emerson bolstered their capabilities and reach. Today, ASCO's legacy in fluid control continues, with the brand standing as a testament to expertise, innovation, and excellence in the industry.

ASCO Solenoid Valves

ASCO, a prominent name in the fluid automation industry, offers a comprehensive range of solenoid valves catering to various applications and industries. Some of the types of solenoid valves offered by ASCO include:

General Service Valves

ASCO general service valves are versatile solenoid valves designed to handle a wide range of applications and media, including air, water, light oil, and inert gases. Unlike special service valves tailored for specific or extreme conditions, general service valves are built to address common and everyday fluid control needs in various industries. They are typically characterized by their ability to operate under standard pressures and temperatures. These valves are often used in tasks such as powering pneumatic equipment, controlling water flow, or managing the release of gases. Due to their general-purpose nature, they are a staple in many industrial settings, commercial spaces, and manufacturing processes. ASCO's commitment to quality ensures that even their general service valves meet high standards of reliability, making them a trusted choice for many users requiring dependable fluid control solutions. General service solenoid valves from ASCO include 2-way, 3-way, 4-way, and electronically enhanced valves.

Learn more about ASCO Electronically Enhanced Solenoid Valves in this video:

Shop ASCO General Service Valves

Special Service Valves

ASCO special service valves are solenoid valves uniquely tailored for specific applications or challenging environments requiring distinct materials, configurations, or operational features. For example, they offer high-temperature valves designed to operate reliably in environments with elevated temperatures, while low-temperature valves function consistently in freezing conditions. Their steam valves, engineered explicitly for controlling steam, can endure the intense heat and pressure typical of steam applications. Fuel, gas, and oil valves cater to the intricacies of managing these mediums. In industries like food, beverage, and pharmaceuticals, ASCO provides sanitary valves that adhere to rigorous sanitary standards, are resistant to corrosion, and are easy to clean. Dust collector valves, essential in systems managing dust and particulates, ensure air quality in industrial settings.

Shop ASCO Special Service Valves

Combustion Valves

ASCO combustion valves are designed specifically for applications related to combustion systems, where they play a pivotal role in controlling the flow of fuel, air, or other gases to burners, boilers, or other combustion equipment. These valves are crucial in ensuring the efficient and safe operation of combustion processes. They often come with features that provide quick shutoff capabilities, ensuring safety by preventing unintended fuel flow, which can lead to dangerous situations. Given the critical nature of combustion processes, whether in industrial furnaces, commercial boilers, or residential heating systems, the reliability and precision of these valves are paramount. ASCO, with its reputation for quality, has developed combustion valves trusted by professionals to deliver consistent performance, ensuring both the efficiency and safety of combustion systems.

Automation Solenoid Valves

ASCO automation valves are integral components designed to regulate, direct, or control the flow of fluids or gases within automated systems. These valves play a significant role in applications where precise fluid or gas control is essential for the automation process. Equipped with actuation mechanisms, these valves can be controlled remotely, responding to signals from a central control system or programmable logic controller (PLC). Given the diverse nature of automated systems in various industries, from manufacturing to processing, ASCO's automation valves are crafted to cater to a wide range of requirements. They can be found in automated production lines, fluid handling systems, and complex robotic operations.

ASCO Solenoid Valve FAQs

What is the difference between direct-acting and pilot-operated solenoid valves by ASCO?

Direct-acting solenoid valves use the solenoid coil to move the valve component directly. In contrast, pilot-operated valves utilize a smaller pilot valve controlled by the solenoid to actuate the main valve through a change in pressure.

How do you mount an ASCO Red Hat solenoid valve?

Mounting an ASCO Red Hat solenoid valve involves several steps to ensure it operates correctly and safely. Here is a general procedure for mounting an ASCO Red Hat solenoid valve:

-

Safety First: Before starting, ensure all electrical power sources are turned off, and the media flow is shut down. This will prevent accidental activation or injury.

-

Choose the Location: Pick a location that provides easy access for maintenance and offers protection from excessive vibration, heat, or other environmental factors that might affect the valve's operation.

-

Orientation: While many ASCO solenoid valves can be mounted in any position, it's generally recommended to install them with the coil vertical for optimal performance. Check the valve's documentation to confirm the preferred orientation.

-

Prepare the Mounting Surface: The surface should be flat and clean. Using a mounting bracket or plate can help secure the valve in place.

-

Thread Preparation: If the valve connects via threaded ports, apply a suitable thread sealant to prevent leaks. Avoid over-application which might contaminate the media.

-

Connect the Valve:

- For threaded connections, screw the valve into place, ensuring a tight seal without over-tightening.

- For flanged or other connection types, follow the manufacturer's instructions, using appropriate gaskets or seals.

-

Electrical Connections:

- Open the coil enclosure or terminal box.

- Connect the wires from the power source to the solenoid coil terminals, adhering to the appropriate voltage and polarity requirements. It's crucial to use the correct voltage rating to avoid damaging the solenoid or creating a safety hazard.

- Ensure all connections are secure, and then close the enclosure.

-

Testing:

- Slowly reintroduce the media flow to check for leaks around the valve connections.

- Energize the coil briefly to verify that the valve actuates correctly. De-energize the coil to ensure the valve returns to its default state.

-

Documentation and Labeling: Label the valve indicating its function, flow direction, and other relevant details. Keeping a record of installation details, model numbers, and maintenance schedules can be beneficial for future servicing or troubleshooting.

-

Regular Maintenance: Periodically inspect the valve for signs of wear, leakage, or damage. Test its function to ensure it's operating correctly.

Note: The exact mounting procedure can vary based on the specific ASCO Red Hat solenoid valve model, the application, and the environment. Always refer to the manufacturer's installation and maintenance instructions provided with the valve for the most accurate and detailed guidance.

How do you reset an ASCO solenoid valve?

Before resetting an ASCO solenoid valve, always prioritize safety by shutting off the power and media supply to ensure the system is depressurized. Begin with a thorough visual inspection of the solenoid valve, looking for signs of wear, damage, or any external obstructions, such as burnt coils or damaged connectors. If the valve comes equipped with a manual override feature, you can use it to see if the valve operates smoothly; afterward, ensure it's returned to its normal position.

Electrical checks are essential, too: verify that the solenoid coil receives the correct voltage and that the coil's resistance, when measured with a multimeter, is within the specified range. If you suspect internal debris or buildup, you might need to disassemble the valve following the manufacturer's guidelines, clean the necessary components, and reassemble it, ensuring all parts are appropriately sealed and aligned.

Once the potential issues are addressed, restore power and media flow to the valve, testing its operation multiple times for correct functioning. It's also wise to evaluate other connected system components, as sometimes the root problem may lie with related controllers, sensors, or electrical connections rather than the solenoid valve itself. If any parts are serviced or replaced during the process, documenting these changes can be invaluable for future maintenance or troubleshooting. If the valve continues to malfunction after these steps, it may necessitate further diagnostics, the procurement of replacement parts, or even the installation of a new valve. Always consult the specific ASCO solenoid valve manual for any particular guidance, or reach out to ASCO support for expert advice.

How do you wire an ASCO solenoid valve?

Wiring an ASCO solenoid valve involves connecting the solenoid coil to a power source so that it can be actuated. Here's a general procedure on how to wire an ASCO solenoid valve:

- Safety Precautions: Always start by ensuring the power supply is turned off. This will prevent any accidental electrical shock or unintentional valve actuation during the installation process.

- Check the Valve's Specifications: Ensure the power supply's voltage and frequency match the solenoid valve's specifications. Connecting a solenoid to an inappropriate power source can damage the coil or reduce its lifespan.

- Access the Solenoid Terminals:

- Many ASCO solenoid valves have a terminal box or a removable enclosure that protects the coil's electrical connections.

- Remove the cover or enclosure to access the solenoid's terminals.

- Make the Connections:

- Generally, a solenoid coil will have two terminals: one for the live wire and another for the neutral wire. If the solenoid valve operates on AC power, the polarity usually isn't a concern, meaning either wire can be connected to either terminal.

- However, for DC-powered solenoid valves, polarity is essential. Ensure the positive (often red or marked with a "+" sign) goes to the positive terminal and the negative (usually black or marked with a "-" sign) goes to the negative terminal.

- Grounding:

- If the solenoid valve has a grounding terminal (often marked with a ground symbol or "GND"), ensure you connect it to the system's ground. Grounding is essential for safety, especially in AC-powered systems.

- Secure the Connections: Ensure that all wire connections are tight. Loose connections can cause erratic valve operation or even damage the solenoid coil.

- Reattach the Enclosure or Terminal Box Cover: Once you've made the connections, replace the cover or enclosure to protect the solenoid coil and its terminals from external factors like moisture, dust, and debris.

- Test the Valve:

- Turn on the power supply.

- Actuate the solenoid valve a few times to ensure it operates correctly. Listen for the characteristic "click" of the valve opening and closing.

- Document and Label: Label the valve with details about its power source, operation, and other relevant data to assist in future troubleshooting or maintenance tasks.

It's essential to note that the exact wiring process might vary depending on the specific model of the ASCO solenoid valve and its intended application. Always refer to the manufacturer's wiring diagram and instructions provided with the valve for precise guidance.