Bell & Gossett heat exchangers offer maximum efficiency for heating and cooling systems. Plate heat exchangers come in a variety of sizes and capacities for optimum heat and thermal transfer in minimal space. In addition, steam and water-powered heat exchangers provide instantaneous heat transfer. Bell & Gossett also offers a complete line of tank heaters, straight tube heat exchangers, tank suction heaters, gas coolers, and compact heat exchangers.

Bell & Gossett Plate & Frame Heat Exchangers

Brazed Plate Heat Exchangers

Compared to conventional shell and tube heat exchangers, Bell & Gossett BPX brazed plate heat exchangers offer the highest thermal efficiency and durability in a compact, low-cost unit. They are one-sixth the size, one-fifth the weight, one-eighth the liquid volume, and one-third to one-fifth the surface area of shell and tube heat exchangers.

Their corrugated plate design provides very high heat transfer coefficients. In addition, the unit’s stainless-steel plates are vacuum brazed together to form a durable, integral piece that can withstand high pressure and temperature.

BPX heat exchangers are available in many different model sizes ranging from 1/4" to 4" port size. They are ideal for industrial oil cooling, refrigerant evaporators and condensers, and residential and light commercial HVAC hydronic systems.

They are also available with copper, or optional-corrosion resistant nickel braze material. Double wall models and ASME code options are also available.

BPX BPDW double wall brazed plate heat exchangers offer the highest leak protection, safety, thermal efficiency, and durability in a compact, low-cost unit. They feature:

- True double wall construction, including port regions

- Double wall plate design with unique air vent leak paths

- Complete peripheral braze for additional strength

- Four dedicated leak ports for quick and easy leak detection

- Excellent performance for domestic and potable water applications

Shop Bell & Gossett Brazed Plate Heat Exchangers

Bell & Gossett BPX Heat Exchangers Brochure

Bell & Gossett BPX Heat Exchangers Sell Sheet

Bell & Gossett BPDW Double-Wall Brazed Plate Heat Exchangers Brochure

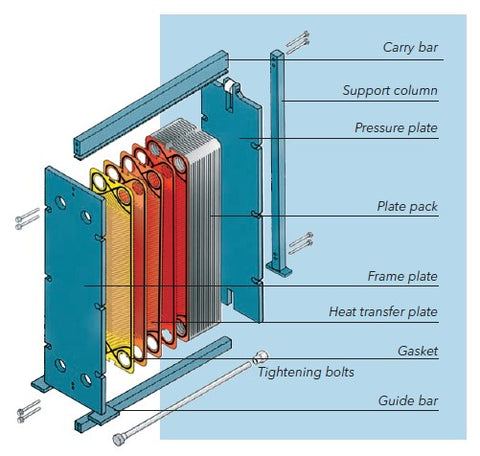

Gasketed Plate Heat Exchangers

Bell & Gossett GPX heat exchangers feature a gasketed plate pack design that is small, lightweight, and highly efficient in transferring heat with either large or small fluid temperature differences. In addition, this design produces high turbulence, resulting in increased heat transfer coefficients, full counterflow of hot and cold fluids, and low fouling – which means minimum surface area requirement.

Bell & Gossett Gasketed Plate & Frame Heat Exchangers – GPX

An innovative plate design allows GPX heat exchangers to provide more heat transfer using less space. As a result, they perform with one-third to one-fifth of the surface area of conventional shell and tube heat exchangers designed for the same application.

- GPX models have a higher surface area to volume ratios than conventional shell and tube heat exchangers.

- GPX offer superior heat transfer coefficients compared to shell and tube heat exchangers.

- GPX offers “true” countercurrent flow, which maximizes the mean temperature difference between fluids.

- GPX technology offers maximum efficiency in less space, with outstanding application flexibility.

Bell & Gossett Gasketed AP AHRI Certified Plate & Frame Heat Exchangers

Bell & Gossett GPX “AP” plate heat exchangers are certified to the AHRI Standard 400 for liquid-to-liquid heat exchangers, which establishes definitions, test requirements, minimum data requirements for published ratings, marking, nameplate data, and conformance conditions. But most importantly, it provides independent third-party certification of performance ratings through yearly testing. All of this provides a verified design for heat exchanger selection, ensuring performance as specified which protects the customer and engineer on startup, eliminates the need for field testing, and allows system operation with optimal energy efficiency.

Bell & Gossett GPX Heat Exchangers Brochure

Bell & Gossett Steam & Water-Powered Heat Exchangers

U-Tube Heat Exchangers

Bell & Gossett offers U-Tube heat exchangers for water-to-water or steam-to-water HVAC, plumbing, or process applications. Model SU is designed for applications using steam on the shell to heat fluids in the tubes, and the WU product is designed as a liquid-to-liquid heat exchanger. These shell and tube heat exchangers feature an all-welded, rugged carbon steel shell with a stainless steel option, providing maximum durability.

Key features of U-Tube heat exchangers:

- Removable bundle for ease of inspection and replacement

- This design allows for differential thermal expansion between the shell and tubes as well as between the individual tubes

- The result is a heat exchanger capable of withstanding thermal shock

- The bundle design and tube layout allow maximum heat transfer surface area per given shell size

- SU/WU shell and tube heat exchangers are also available with Diamondback double wall tube construction and heavy-duty construction for high-temperature applications, as well as tank heater designs

Bell & Gossett SU Heat Exchangers

SU heat exchangers are instantaneous-type heat exchangers designed to heat liquids with steam. No expensive, space-wasting storage tank is needed. Although the SU is used for heating many types of fluids, its most common application is for heating water. SU heat exchangers can also be used as a converter for radiation, radiant panels, and snow melting systems. They are available in diameters of 4" through 30".

Bell & Gossett WU Heat Exchangers

WU heat exchangers provide instantaneous water-to-water heat transfer—with pumped boiler water circulation. The WU, equipped with a Bell & Gossett booster pump, pumps boiler water through the shell, thereby significantly increasing the heater's capacity. As a result, large volumes of hot water are produced by a minimal unit. Sizes range from 4" diameter through 30" diameter.

Bell & Gossett SU/WU U-Tube Heat Exchangers Brochure

Shop Bell & Gossett Shell & Tube Heat Exchangers

Bell & Gossett Tank Heaters

Bell & Gossett tank heaters are two-pass U-bend heat exchangers. A Bell & Gossett tank heater offers many advantages, as it heats and stores the water in the same unit. It can be operated by passing steam or hot water through the coil and is an excellent heater for hard water territories. Its large capacity in small spaces makes this heater particularly suitable for boiler rooms with low headroom.

Bell & Gossett TCW and TCS tank heaters are shell and tube style heat exchangers. The tube bundle is U-bend construction with tube ends expanded into a stationary tube sheet. This construction permits ample expansion or contraction for wide temperature variations. Fluid in the tank is heated by another fluid or steam circulated through the tubes. Primarily for natural convection in the tank, model TCS heads are furnished with tappings for steam, condensate, vacuum breaker, and vent connections. Model TCW heads are furnished with tappings for water connections.

Key features of Bell & Gossett tank heaters:

- 3/4" O.D. copper tubes

- Cast iron heads (brass can be furnished on request) rated to 375°F

- Pressure vessel-quality steel tube sheets and welding collars (brass tube sheets can be furnished on request)

- Brass tube supports

- All materials furnished for pressure parts are certified to ASME specifications

- Units are available with stainless steel, 90/10 cupro-nickel, Admiralty, and steel tubing

- Many tank heater applications require lining the tank with various materials, i.e., epoxy phenolic, cement, etc. When the thickness of these linings exceeds 0.01″, oversized construction must be provided.

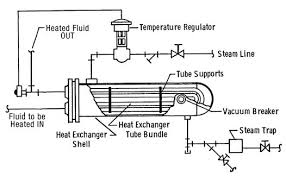

Typical Bell & Gossett U-Tube Heat Exchanger Piping Diagram

Straight Tube Heat Exchangers

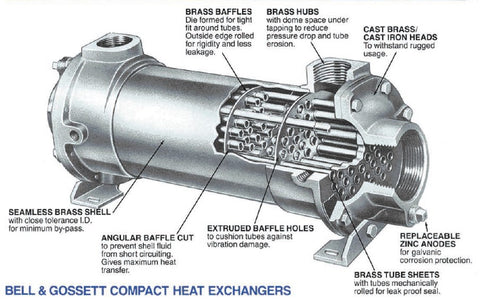

Bell & Gossett CHX Small Coolers

Bell & Gossett Compact Heat Exchangers (CHX) are designed to satisfy the heat transfer requirements of industrial applications. CHX heat exchangers incorporate advanced design techniques. Each unit has been computer designed to be the best size for the job. The angular baffle cut design prevents shell fluid from short-circuiting, ensuring maximum heat transfer for your investment. Bell & Gossett designs are matched in quality by advanced manufacturing techniques. Unit components are precision die formed to provide an extremely tight fit.

Bell & Gossett Compact Heat Exchangers Brochure

Bell & Gossett Aftercooler Heat Exchangers

Bell & Gossett aftercoolers are designed to cool compressed air for safer pneumatic equipment handling and to remove moisture and oil from compressed air. They feature full-size air connections for reduced pressure drop, easy condensed water removal, and a counterflow design for close approaches.

- Model ACA is designed with a floating rear tube sheet to compensate for expansion or contraction of the tube bundle. The bundle is removable.

- Model AFCR is a compact, fixed-tube sheet style aftercooler with a maximum length of 50".

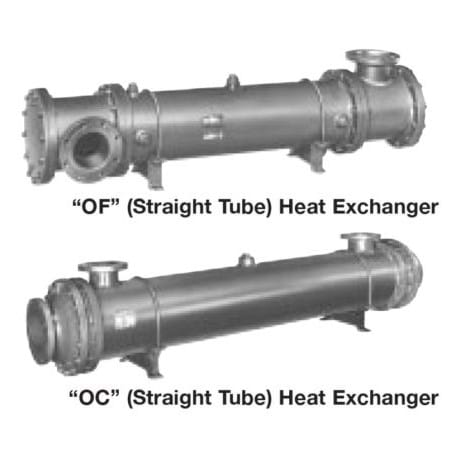

Bell & Gossett Straight Tube Design Heat Exchangers

Bell & Gossett OF (Straight Tube) Heat Exchangers

Model OF heat exchangers with fixed tube sheets that have straight tubes of 5/8" and 3/4" O.D. are excellent when heavy fouling fluids are inside tubes, and light fouling fluids are in the shell. However, when wide temperature differences or abrupt temperature changes occur between tube and shell side fluids, an expansion joint must be used.

Bell & Gossett OC (Straight Tube) Heat Exchangers

These units feature removable tube bundles with an internally packed floating head. They have a wide range of applications involving the transfer of heat between fluids. Sizes range from 6" through 32" in diameter; lengths range from 2' through 24'. Standard materials include steel shells and tube sheets, cast iron heads, and copper or steel tubes. Their design can vary for channel or bonnet heads in single and two-pass construction.

Bell & Gossett GC Gas Coolers

Bell & Gossett GC gas coolers cool gases that enter tubes at 1000ºF or lower by using water. They have 1/2" or 5/8" O.D. tubes.

Bell & Gossett Heat Exchangers Brochure

Bell & Gossett Heat Transfer Parts

Bell & Gossett offers replacement parts for heat transfer products, including tube bundles, heads, gaskets, and more.

Heat Transfer Replacement Parts & Master Cross-Reference List

Bell & Gossett Heat Exchanger Sizing & Selection

Main Criteria for Heat Exchanger Sizing & Selection

- Function that the heat exchanger will perform (whether condensing, boiling, etc.)

- Pressure limits (high/low), which may vary throughout the process, and pressure drops across the exchanger

- Approach temperature and temperature ranges (which may vary throughout the process)

- Fluid flow capacity

- Materials requirements. Conditions like sudden temperature changes or corrosive media may require special materials. For a gasketed plate heat exchanger, the gaskets must be compatible with the fluids in the unit.

- Thermal fluid characteristics and product mix. If the heating or cooling fluid is susceptible to fouling, a corrosion resistant material may be needed.

- Location. Some exchangers may require cooling water, steam, or hot oil, and they may be relevant options only where these utilities are available.

- Footprint. Space limitations and layout may also affect which heat exchanger models are suitable. Keep in mind that lower approach temperatures generally correlate to larger units.

- Maintenance requirements. Choosing a design that lends itself to easy cleaning may be helpful depending on housekeeping procedures. Ease of repair or inspection may be a factor as well.

Generally, more than one heat exchanger model will work for a given application, so additional criteria may help evaluate the best fit. For example, consider factors like future scalability, the overall cost to purchase and operate, and efficiency/carbon footprint to narrow the options.

Once a heat exchanger design is selected, the most efficient size depends on operating conditions. For example, the winter and summer cooling (or heating) load must be calculated if operating temperatures vary seasonally. The most efficient plate exchanger model is often the smallest model with the same plate corrugation capable of handling the flow in both seasons.

Thermodynamic equations can help arrive at the best solution, where flow, temperature, and pressure drop are all within acceptable limits. Due to the number of dependent variables in heat transfer solution sizing and selection, complex equations are often used for selecting the optimal solution. Heat exchangers can often be tailored, and specifications like the size and number of plates are often customized for the application.

Bell & Gossett Heat Exchanger Selection

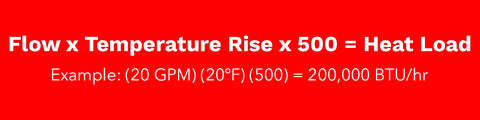

Estimate how much heat you need using this formula:

Use the ESP Systemwise program to select the correct Bell & Gossett heat exchanger for your system.

Most brochures and technical bulletins from Bell & Gossett for heat exchangers provide a selection chart as well.

Bell & Gossett Heat Exchanger Sizing

Bell & Gossett offers heat exchangers in a wide variety of sizes and styles to fit any application. Use the ESP Systemwise program to select the correct Bell & Gossett heat exchanger for your system.