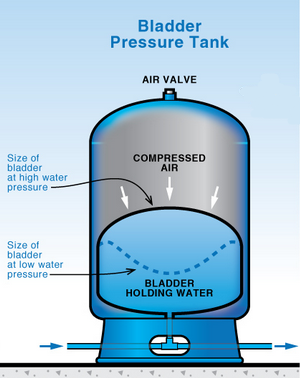

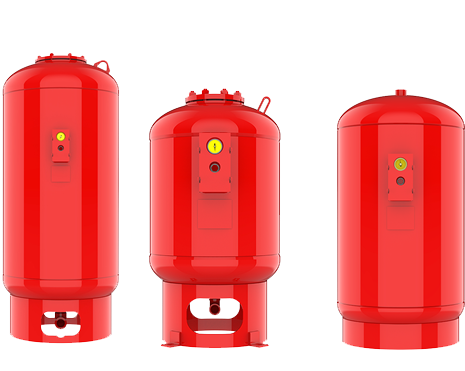

Bladder Tanks

A bladder expansion tank uses a balloon-like bladder to adjust to pressure changes and absorb thermal expansion within a heating and cooling system. The bladder separates the expanded water from the air. This way, the water does not come into contact with the tank and prevents corrosion by oxygen and rusting. It also increases pump life by reducing the number of pump cycles. In addition, this system prevents water clogging by using an air wall between the tank’s interior and the bladder’s exterior.

Bladder tanks utilize space inside the tank to create pressurized air. That pressurized air then pushes water at a psi depending on the configuration and intended use. The more water a pressure tank loses, the less powerful the air pressure is. The air pressure in a bladder pressure tank continues to thrive because of the vacuum created by the tank and balloon. The major advantage of bladder-type expansion tanks is that the bladder is replaceable.

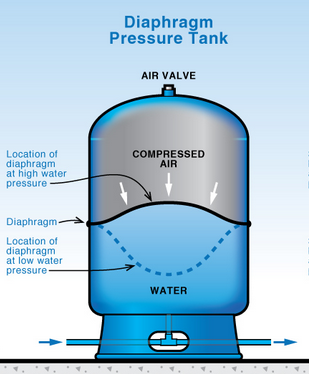

Diaphragm Tanks

Diaphragm tanks are water vessels that are subject to a high amount of pressure. The diaphragm keeps the water and air separate inside the tank. It keeps the system from being waterlogged and prevents the absorption of air.

Diaphragm pressure tanks are the most efficient type of pressure tank and require the least amount of maintenance due to the use of a rubber lining inside that separates the air and the water. This rubber lining acts as the bladder would, but its connection is permanent to the tank. Therefore, it is not replaceable. However, the lining doesn’t take up as much space as the balloon-like bladder, increasing efficiency.

Diaphragm pressure tanks are divided into the upper water storage area and the lower air pressure area, with a rubber diaphragm separating the two areas. When the tank begins to store water, the weight of the water will squeeze the rubber toward the lower air pressure zone. As a result, the pressure in the air pressure zone will become larger and larger (the air can be compressed). The pump stops pumping water when the pressure exceeds the high pre-set value. On the contrary, when there is water demand, the air in the air pressure zone is released, and the rubber diaphragm is compressed. As a result, the water squeezed toward the joint, causing the water to flow out.

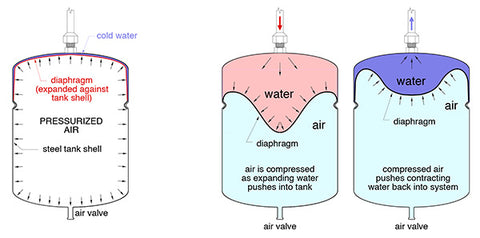

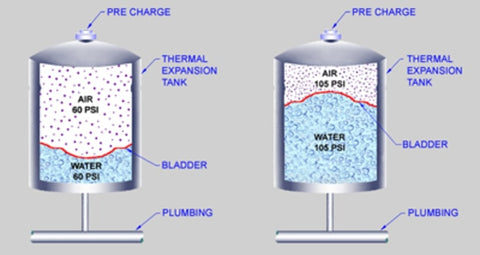

Pre-Charged Expansion Tanks

Pre-charged expansion tanks can contain either a bladder or a diaphragm. When a tank is pre-charged to the minimum system operating pressure (PMIN), it accepts only the expanded system water as the temperature increases. The highest temperature condition will compress the pre-charge to the maximum system operating pressure (PMAX). As the temperature decreases, the tank pressure pushes the expanded water back into the system. This design allows for a smaller tank since space for charge water to compress air at atmospheric pressure to PMIN is no longer necessary, as it is when using a conventional expansion tank.

Bladder & Diaphragm Expansion Tanks Available from Different Manufacturers

Bell & Gossett Bladder Expansion Tanks

Bladder expansion tanks from Bell & Gossett contain a balloon-like bladder or rubber membrane within the shell that can be replaced when required. Pre-charged bladder expansion tanks from Bell & Gossett absorb thermal expansion forces in hydronic heating and cooling systems. Their rubber membranes isolate the air from the system fluid, preventing waterlogging, and the pre-charge minimizes the size of the tank.

Shop Bell & Gossett Bladder Expansion Tanks

Bell & Gossett Diaphragm Expansion Tanks

Bell & Gossett diaphragm expansion tanks contain a butyl rubber diaphragm attached to an internal polypropylene tank liner. The heavy-duty butyl diaphragm separates system water from the air in the tank preventing water logging problems. Diaphragms cannot be replaced independently. The entire tank would need to be replaced if there was a problem with the diaphragm. However, the diaphragm is made of thick, high-quality rubber that will last for years.

Shop Bell & Gossett Diaphragm Expansion Tanks

Taco Bladder Expansion Tanks

Taco offers several models of bladder-style expansion tanks which utilize butyl rubber bladders to permanently separate the air charge from the system fluid in the expansion tank. Taco bladder expansion tanks are designed for hydronic systems, hydro-pneumatic, and draw-down applications.

Shop Taco Bladder Expansion Tanks

Taco Diaphragm Expansion Tanks

Taco diaphragm expansion tanks control the pressure in hydronic systems in commercial, institutional, and industrial applications. Diaphragm tanks use a diaphragm to separate the air and water permanently. In a diaphragm tank, the air is held captive by using a diaphragm, with the expanded water being held on one side of the diaphragm and air on the other.

Shop Taco Diaphragm Expansion Tanks

Armstrong Bladder Expansion Tanks

Armstrong Type L bladder expansion tanks feature 10 to 1056 US GPM flow. Expansion tanks from Armstrong eliminate air ingress and dampen pressure transients (water hammer) for reduced system corrosion and stress, ultimately extending service intervals and overall system life.

Request a Quote for an Armstrong Bladder Expansion Tank

Armstrong Diaphragm Expansion Tanks

Armstrong AET plain steel expansion tanks feature 15 to 525 US GPM flow, while AX diaphragm expansion tanks feature 8 to 211 US GPM flow. Expansion tanks from Armstrong use compressed air to maintain system pressures by accepting and expelling the changing volume of water as it heats and cools. They isolate the expanded water from the pressure-controlling air cushion, which is pre-charged at the factory and can be adjusted in the field to meet final system requirements.