Maxitrol's Selectra modulating valves are a line of innovative gas pressure regulators designed to provide accurate and reliable control of gas flow rates in a wide range of industrial and commercial applications. These valves use advanced electronic control systems to adjust the pressure and flow of gas in real time, ensuring consistent and efficient performance.

One of the key features of Selectra modulating valves is their ability to modulate the gas flow rate over a wide range, from just a few cubic feet per hour up to thousands of cubic feet per hour. This makes them ideal for use in applications that require precise control of gas flow rates, such as in HVAC systems, industrial burners, and process heating applications.

Selectra modulating valves are available in direct-acting and pilot-operated configurations, providing a range of options to suit different application requirements. They are also designed to be easy to install and maintain, with minimal downtime for servicing or repair.

In addition to their precision control capabilities, Selectra modulating valves are also designed with safety in mind. They feature a variety of built-in safety features, including pressure relief valves, gas leak detection sensors, and flame arrestors, to ensure that they operate safely and reliably even in challenging environments.

Overall, Maxitrol's Selectra modulating valves are a versatile and reliable solution for precise gas flow rate control in various industrial and commercial applications.

Types of Maxitrol Selectra Modulator Valves

Selectra Modulator Valves

Maxitrol’s unique modulator valves provide precise, non-fluctuating, instantaneous temperature control without requiring a motor or mechanically driven butterfly valve. As a result, they are suitable for natural, manufactured, mixed, liquefied petroleum, and liquefied petroleum gas-air mixtures. The H and H‑1 models are ideal for use with liquefied petroleum and other applications.

Selectra Modulator Valves are available in the following pipe sizes:

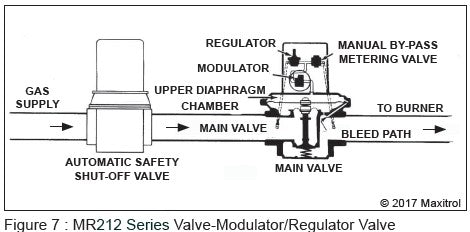

Selectra Modulator-Regulator Valves

MR valves perform the dual functions of modulation and pressure regulation. They are suitable for natural, manufactured, mixed, liquefied petroleum, and liquefied petroleum gas-air mixtures. The H and H‑1 models are ideal for use with liquefied petroleum and other applications.

Selectra Modulator-Regulator Valves are available in the following pipe sizes:

Shop All Maxitrol Selectra Modulator Valves

How to Choose a Selectra Modulator or Modulator-Regulator Valve

Choosing the right Selectra modulating or modulator-regulator valve will depend on several factors, including the application requirements, the type of gas used, and the specific performance features needed. Here are some key factors to consider when selecting a Selectra valve:

- Application:

- Direct-fired (negative pressure) burners

- Atmospheric burners

- High outlet pressures (such as LP applications)

- Maximum current draw in amps

- Valve function

- Inlet pressure and operating limits

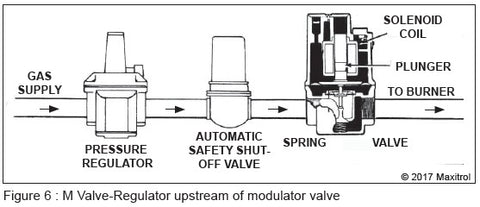

- Whether or not an upstream pressure regulator is required

- Maximum emergency exposure pressure

- Output control means

- What Maxitrol system will it be used with

Learn more from the Maxitrol Selectra M/MR Modulating Valves Catalog

Maxitrol Selectra Modulator Valve Installation

Modulator and Modulator-Regulators valves should be mounted upright in a horizontal pipe run downstream of other controls – a separate gas pressure regulator must be used with any Modulator valve – in typical direct-fired and in-direct fired gas trains.