Pressure Independent Control Valves (PICVs) regulate the flow of water or air to maintain a consistent temperature and pressure in the building. Unlike traditional control valves, which regulate flow based on the pressure differential across the valve, PICVs maintain a consistent flow rate regardless of changes in pressure.

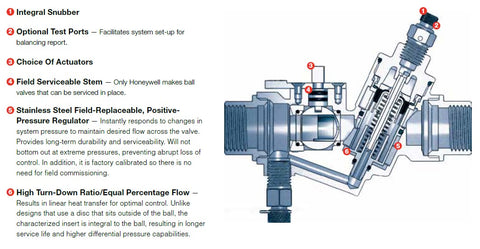

PICVs typically consist of a control valve, a differential pressure regulator, and a flow limiter. The control valve adjusts the flow of water or air while the differential pressure regulator maintains a constant pressure drop across the valve. The flow limiter ensures a constant flow rate, even if the differential pressure regulator fails or there are changes in system demand.

By maintaining a consistent flow rate and pressure, PICVs offer several benefits over traditional control valves, including improved energy efficiency, reduced maintenance requirements, and more precise temperature control. As a result, they are commonly used in commercial and residential buildings, hospitals, schools, and other facilities where precise temperature and pressure control is critical.

How a Pressure Independent Control Valve Works

Pressure Independent Control Valves (PICVs) regulate the flow of fluid in HVAC systems, independent of pressure fluctuations in the system. They combine the functions of a control valve, a pressure regulating valve, and a flow limiter into a single device.

The control component of a PICV modulates fluid flow through the valve in response to control signals from a thermostat or a Building Management System (BMS), typically through an actuator that adjusts the valve opening based on the desired flow rate.

PICVs have an integrated pressure-regulating mechanism, usually a diaphragm or a spring-loaded mechanism, that continuously adjusts to maintain a constant differential pressure across the control valve, regardless of fluctuations in the system pressure. This ensures that the flow control component can effectively modulate the flow rate without being affected by pressure changes.

PICVs also include a flow limiter, usually adjustable, to set the maximum flow rate allowed through the valve, prevent excessive flow, and ensure that the specified flow rate is not exceeded, even when the control valve is fully open.

PICV Benefits for HVAC Systems

Using Pressure Independent Control Valves (PICVs) in HVAC systems offers numerous benefits, including:

- Enhanced Temperature Control – PICVs help maintain a constant flow rate through the system, leading to accurate temperature control and better comfort levels in different building zones.

- Improved Energy Efficiency – PICVs contribute to energy savings by maintaining the correct flow rate across heat exchangers and enabling pumps to operate at lower speeds. They also reduce the need for system balancing, which minimizes energy consumption in HVAC systems.

- Simplified System Design & Installation – By combining the functions of control and balancing valves into a single device, PICVs simplify the overall design and installation process. This results in reduced material and labor costs and a more streamlined system.

- Reduced Maintenance – Since PICVs combine the functions of multiple valves, there are fewer components to maintain and service.

- Better System Balance – PICVs automatically adjust to pressure fluctuations, continuously maintaining the correct flow rate and eliminating the need for manual balancing. Using PICVs reduces the risk of over or under-sizing system components and improves overall system performance.

- Enhanced System Flexibility – PICVs can accommodate changes in the building's occupancy or usage patterns without significantly altering the HVAC system, making them suitable for a wide range of applications.

Honeywell Advantages of Pressure Independent Control Valves Whitepaper

Pressure Independent Control Valve Applications

Commercial Buildings

Pressure Independent Control Valves (PICVs) are widely used in commercial buildings to enhance the performance, efficiency, and flexibility of HVAC systems. Their applications in commercial buildings can include VAV systems, fan coil units, radiant systems, heat pumps, geothermal systems, domestic hot water, process heating and cooling, and more.

The applications of PICVs in commercial buildings are diverse and can significantly contribute to the efficiency, comfort, and overall performance of HVAC systems. By maintaining optimal flow rates and pressure, PICVs help ensure precise temperature control and reduce energy consumption, ultimately leading to cost savings and a more comfortable environment for occupants.

Residential Buildings

Pressure Independent Control Valves (PICVs) can also be used in residential buildings to improve the performance, efficiency, and comfort of HVAC systems. Some common applications of PICVs in residential buildings include domestic hot water, radiant heating and cooling, hydronic heating, heat pumps, geothermal systems, solar, snow and ice melt, multi-zone systems, and more.

By incorporating PICVs in residential HVAC systems, homeowners can benefit from improved temperature control, increased energy efficiency, and reduced maintenance requirements. These advantages contribute to enhanced comfort and lower operating costs for homeowners.

Factors to Consider When Selecting a PICV

While Pressure Independent Control Valves (PICVs) offer numerous benefits, they also have certain challenges and limitations that need to be considered in the design, installation, and operation of HVAC systems:

- Initial Cost – PICVs can be more expensive upfront than traditional control and balancing valves. However, the long-term benefits, such as energy savings, improved performance, and reduced maintenance, can outweigh the initial cost.

- System Compatibility – Not all HVAC systems may be compatible with PICVs or require additional modifications to work effectively. Proper system design and integration are crucial to ensure compatibility and maximize the benefits of using PICVs.

- Sizing & Selection – Select the correct valve for your application by choosing a valve that matches the coil design flow rate. Select the smallest valve capable of delivering this design flow rate, but round up to the next size when needed. Incorrect sizing can lead to reduced efficiency, poor temperature control, and increased wear on system components. It is essential to choose the correct PICV for the system.

- Maintenance – Although PICVs typically require less maintenance than traditional valve systems, they still need regular inspection and maintenance to ensure optimal performance. This includes checking for leaks, ensuring the actuator functions correctly, and verifying the flow settings are accurate.

- Pressure Range – PICVs are designed to operate within specific pressure ranges, and their performance may be affected if the system pressure falls outside these limits.

- Flow Measurement – Some PICVs may not provide highly accurate flow measurement data, which can be a limitation in applications where precise flow data is critical. In such cases, separate flow meters may need to be installed for accurate measurement and monitoring.

Honeywell Pressure Independent Control Valve Quick Selection Guide

Pressure Independent Control Valve Installation

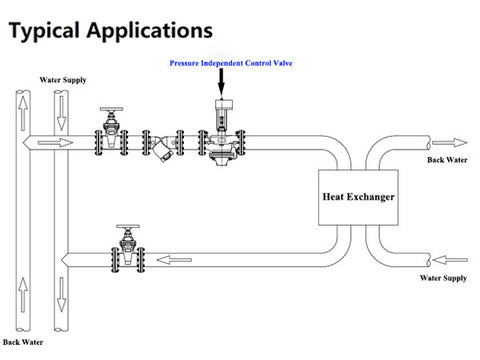

A Pressure Independent Control Valve (PICV) is typically installed as part of an HVAC system's hydronic circuit to regulate fluid flow and maintain consistent flow rates regardless of pressure fluctuations.

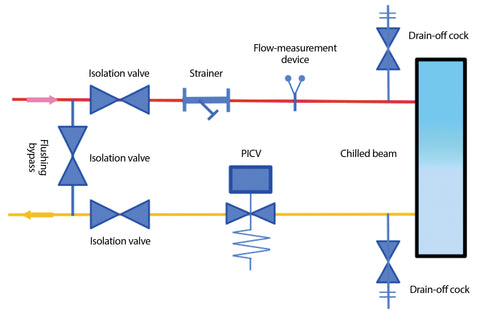

Ensure that the site is clean and debris-free and that the pipes are properly aligned and supported. Also, confirm that the valves and system components are easily accessible for maintenance and adjustments. The installation process for a PICV may vary depending on the specific model and manufacturer's guidelines. Generally, PICVs should be installed with the flow direction arrow on the valve body aligned with the flow direction in the pipe. To ensure accurate flow control, the valve should be installed in a straight section of pipe, with a recommended minimum length of straight pipe before and after the valve. Typically, this would be five pipe diameters upstream and three pipe diameters downstream, although manufacturer recommendations should be followed. Installing isolation valves will make maintenance easier.

PICVs have small channels in the valve body to either side of the diaphragm, making good water quality important. Installing strainers installed before each valve removes relatively large contaminants and protects the system's coils and equipment; however, they will not filter very tiny particles. Ensuring media quality with ongoing water treatment and filtration with a side stream (bypass) filter is essential.

Attach the actuator to the valve according to the manufacturer's instructions—this may involve mounting the actuator onto the valve stem and securing it with screws or clips. Ensure that the actuator is correctly aligned and firmly attached to the valve. Then connect the control wiring from the actuator to the appropriate control system, such as a thermostat or Building Management System (BMS).

After the installation, the system should be commissioned and balanced to ensure proper operation. Commissioning involves:

- Adjusting the flow settings on the PICV,

- Checking for leaks,

- Verifying the actuator's operation, and

- Monitoring system performance.

Proper commissioning also includes flushing the system.

In addition, if the pump speed is controlled with a remote differential pressure sensor, placing the sensor on the PICV located furthest from the pump will achieve the most significant savings. This way, the pump is driven to develop only the head required to support the system's most remote valve and coil.

Honeywell Pressure Independent Control Valves

VRN Pressure Independent Control Valves and Actuators

Honeywell VRN2 two-way dynamic pressure-regulating control valves maintain a constant flow of hot or chilled water with glycol solutions up to 50% in closed-loop heating, ventilating, and air conditioning systems, within the model's specified pressure drop range.

Features & Benefits:

- 1/2" to 3" with internal (female) NPT connections

- Regulated flow rates of 1 to 95 GPM with multiple maximum flow rates available

- Differential pressure regulator for constant pressure drop across the valve seat

- Positive pressure, rolling diaphragm regulator design for flow control accuracy of ±5%

- Equal percentage flow characteristic using patented flow control ball insert

- Patented ball seals for low operating torque

- Nickel-chrome plated brass or stainless steel trim

- Choice of factory-installed actuation: floating, modulating (2-10 V), spring return or non-spring return 2-position, spring return modulating/floating, spring return Sylk-enabled

- Removable, manual operating handle to control valve during installation or in the event of power failure

- Upstream test port for venting or pressure gauge attachment

- Three actuator orientations on the valve for cramped spaces

- Integral snubber eliminates the effect of system pressure fluctuations and entrapped air while improving flow performance

Shop Honeywell Pressure Independent Control Valves

Honeywell VRN2 Pressure Independent Control Valves Product Data

Honeywell VRN2 Pressure Independent Control Valves Installation

VRW2 Dynamic Pressure-Regulating Flanged Control Valves

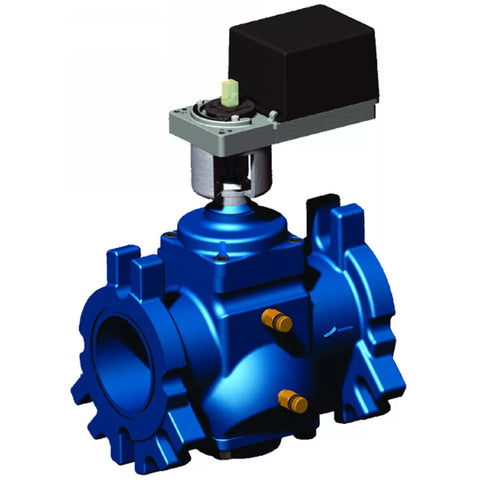

Honeywell VRW2 2-way dynamic pressure-regulating control valves maintain a constant hot and chilled water flow in closed-loop HVAC systems regardless of head pressure fluctuations above the minimum specified pressure drop. In addition, these valves come complete with proportional, stay-in-place, or electronic fail-safe actuators.

The built-in differential pressure regulator maintains fluid flow through the valve independent of changes in supply pressure, eliminating "hunting" by the control system, even at low coil flow. In addition, the pressure regulator virtually eliminates cavitation in the valve and decouples the control valve from the effects of piping components such as reducers and elbows.

Pressure independent control valves are sized to match the design coil flow regardless of coil size. VRW2 valves eliminate the need to balance the system for proper flow and allow chillers to operate at design temperature differential for maximum efficiency at every load condition. 3-way valves and coil bypass lines are not required when used in a system with variable-speed pump drives.

Features & Benefits:

- 2-1/2" to 6" pipes with wafer-flanged connections

- Combination ANSI/ASME Class 150/300 flange connections

- Controls hot or chilled water with up to 50% glycol

- Regulated flow rates from 40.7 to 468 GPM

- Stainless steel pressure regulator maintains constant pressure drop across the valve seat

- Positive pressure rolling diaphragm regulator design for long service life provides flow control accuracy of ±5%

- Equal percentage flow characteristic using multi-turn, non-rising, characterized plug

- High close-off rating

- 50 discrete, selectable flow rates available per valve size

- Stainless steel trim

- Actuators are certified: Safety Extra-Low Voltage, Class II wiring only

Shop Honeywell Pressure Independent Control Valves

Honeywell VRW2 Dynamic Pressure-Regulating Flanged Control Valves Product Data

Honeywell Pressure Independent Control Valve Quick Selection Guide

Honeywell Advantages of Pressure Independent Control Valves Whitepaper