McDonnell & Miller flow switches are known for their efficiency, durability, and versatility and have become a staple in numerous applications. They are versatile and reliable devices designed to accurately monitor and control the flow of fluids in various systems. With features such as ease-of-installation, broad operating temperature and pressure ranges, and high-quality materials, they offer reliable solutions for fluid flow management.

What is a Flow Switch?

A flow switch is a device used to monitor and control the flow of fluid (either liquid or gas) within a system or pipeline. Its primary purpose is to send a signal or activate a response when the flow rate of the fluid goes beyond or falls below a predetermined threshold.

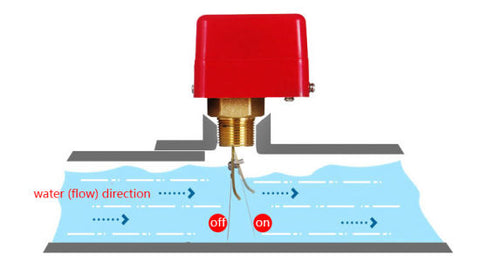

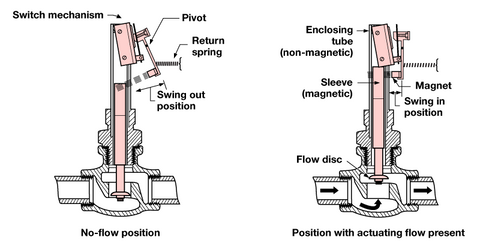

Flow switches use a mechanical device or sensor, often referred to as a paddle or vane, which moves or changes in response to the fluid's flow. This movement triggers a switch, usually a microswitch, which sends a signal to a pump, alarm, or control system. This signal could, for instance, shut off a pump if there's no fluid flow, preventing it from running dry and getting damaged.

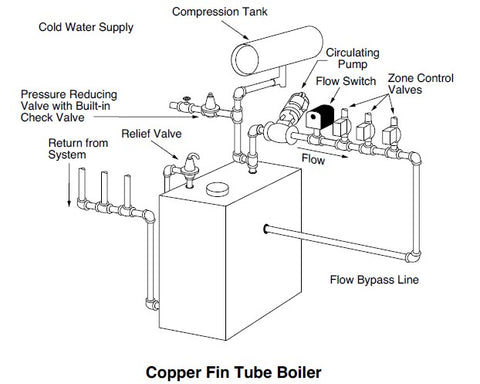

Flow switches are widely used in many applications, including HVAC systems, industrial processes, and water treatment plants. They are crucial in ensuring these systems operate safely and efficiently by managing fluid flow.

Types of Flow Switches

Flow switches are available in various types and designs, each with unique advantages and specific applications. Some of the most common types include:

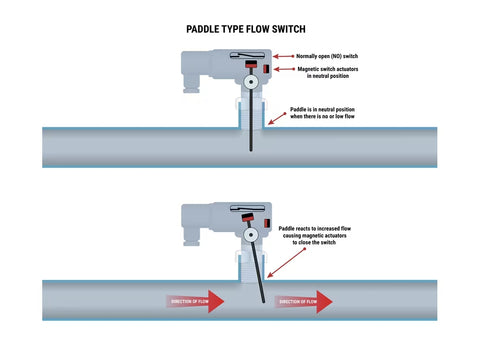

Paddle Flow Switches

These are the most common type of flow switches. They consist of a paddle or vane that moves when fluid passes through it. The motion of the paddle triggers a microswitch, thereby activating a response. Paddle flow switches are primarily used in water and air systems.

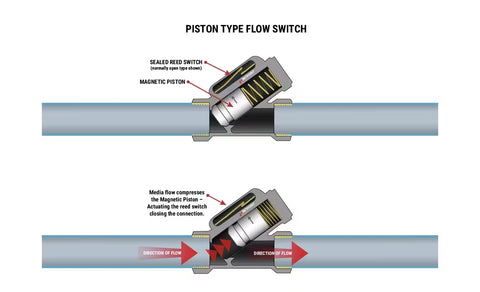

Piston Flow Switches

Piston flow switches use a piston or shuttle that moves in response to changes in fluid flow. When the fluid reaches a certain flow rate, it pushes the piston, which actuates a switch. These types of flow switches are typically used in lubrication and hydraulic systems.

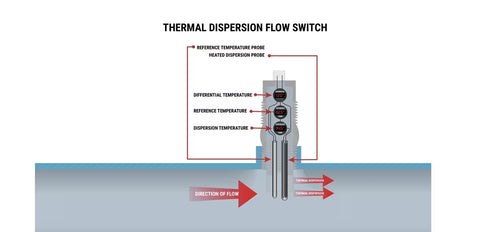

Thermal Flow Switches

These switches measure changes in the thermal properties of a fluid to detect flow rate changes. They consist of a heated sensor and a temperature sensor. When fluid flows past the heated sensor, it cools down; this temperature change determines the flow rate. Thermal flow switches are often used when mechanical flow switches are unsuitable, such as in the chemical industry or in systems handling corrosive fluids.

Optical Flow Switches

Optical flow switches use infrared light to detect changes in fluid flow. These switches contain an infrared light emitter and detector. When there's no fluid flow, the infrared light directly hits the detector. But when fluid starts to flow, it refracts the light, causing changes in the light received by the detector, thus triggering the switch. Optical flow switches are ideal for use in sterile environments like medical or biotechnology applications, as they don't involve moving parts.

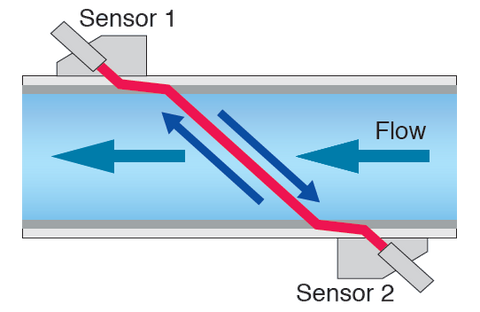

Magnetic Flow Switches

Also known as mag flow switches, these use the principles of magnetic fields and electrical conductivity to detect changes in fluid flow. They apply a magnetic field to the fluid, and when it flows, it generates a voltage proportional to its velocity. Magnetic flow switches are suitable for detecting flow rates in conductive fluids.

Who is McDonnell & Miller?

McDonnell & Miller, a leading brand in the boiler control market, has been producing top-notch flow switches since 1924. Their innovative solutions cater to the needs of a diverse range of industries, including HVAC, industrial processing, and water treatment, among others.

Learn more about McDonnell & Miller

McDonnell & Miller Flow Switch Features & Benefits

McDonnell & Miller has an impressive line-up of flow switches known for their robustness and reliability. McDonnell & Miller Flow Switches offer a comprehensive flow control solution that combines versatility, reliability, and ease of use. Their advanced features and benefits make them an ideal choice for a wide range of applications, from HVAC systems to industrial processes and beyond.

Versatility

One of the standout features of McDonnell & Miller flow switches is their versatility. These switches come in various models to accommodate different fluid types (such as liquid, steam, or gas), making them suitable for many applications across diverse industries.

Easy Installation & Maintenance

McDonnell & Miller flow switches are designed for easy installation and low maintenance. Many models feature a field-adjustable vane length to accommodate different pipe sizes and flow rate requirements. This adaptability allows for a straightforward installation process and easy ongoing maintenance.

Reliable Performance

With their sturdy construction and quality materials, McDonnell & Miller flow switches ensure reliable and consistent performance even in demanding conditions. They are built to resist wear and tear, providing a long-lasting solution for flow control needs.

Wide Operating Range

McDonnell & Miller flow switches can operate under a wide range of temperatures and pressures, making them suitable for applications in various environmental conditions. Whether used in a high-temperature industrial process or a low-temperature HVAC system, these switches ensure accurate flow detection and control.

Safety Enhancements

Safety is a key priority in any fluid handling system, and McDonnell & Miller flow switches contribute significantly to this aspect. By providing precise control and monitoring of fluid flow, these switches help prevent pump damage due to dry running or system failures due to flow anomalies.

High-Quality Materials

McDonnell & Miller flow switches are built with high-quality materials like brass, stainless steel, and other corrosion-resistant compounds. This enhances their durability and ensures they can withstand challenging working conditions.

Integrated Design

Many McDonnell & Miller flow switches feature an integrated design that combines the flow switch with other elements, such as a check valve or a strainer. This not only saves space but also simplifies the installation and maintenance processes.

McDonnell & Miller Flow Switch Series & Models

McDonnell & Miller Series FS1 High Sensitivity Liquid Flow Switches

FS1 switches are ideal for general-purpose applications where high sensitivity is required and moderate or low flow rates are encountered, such as air conditioning, heating, and hydronic systems, water, fuel oil, some viscous liquids, and oils in process work.

Features:

- In-line configuration eliminates the need for a pipe tee

- High flow capacity

- 1/2" NPT

- Single pole, double throw snap switch

- Switch compartment is completely sealed to protect it from the liquid

- Sensitivity adjusting screw makes flow adjustment easy

- Minimum temperature (fluid or ambient): 32°F (0°C)

- Maximum temperature: 225°F (107°C)

- Maximum operating pressure: 100 psi (7 kg/cm2)

- Optional features:

- BSPT threads

- Gold plated contacts

McDonnell & Miller Model FS1-W High Sensitivity Liquid Flow Switches

FS1-W switches are ideal for general-purpose applications where high sensitivity is required and moderate or low flow rates are encountered, such as air conditioning, heating, hydronic systems, water, fuel oil, some viscous liquids, and oils in process work.

Features:

- In-line configuration eliminates the need for a pipe tee

- High flow capacity

- 1/2" NPT

- Single pole, double throw snap switch

- Switch compartment is completely sealed to protect it from the liquid

- Sensitivity adjusting screw makes flow adjustment easy

- Minimum temperature (fluid or ambient): 32°F (0°C)

- Maximum temperature: 225°F (107°C)

- Maximum operating pressure: 100 psi (7 kg/cm2)

- Optional features:

- BSPT threads

- Gold plated contacts

McDonnell & Miller Series FS250 General Purpose Liquid Flow Switches

Series FS250 liquid flow switches provide greater reliability and lower flow sensing capabilities in a general-purpose flow switch. Their universal design serves the widest variety of applications, such as starting or stopping electrically operated equipment such as signal lights, alarms, motors, automatic burners, metering devices, and others.

Features:

- 1″ NPT connection

- Two electrical knock-outs allow connection from either end

- Sensitivity adjusting screw makes flow adjustment easy

- Single pole, double throw snap switch

- EPDM o-ring sealed

- Four stainless steel paddles included: 1", 2", 3" & 6" (25, 50, 80 & 150mm)

- Minimum temperature (fluid or ambient): 32°F (0°C)

- Maximum temperature: 227°F (107°C)

- Maximum pressure: 160 psi (11.3 kg/cm2)

- Model FS251 – NEMA 1 enclosure

- Model FS254 – NEMA 4 enclosure

McDonnell & Miller Series FS4-3 General Purpose Liquid Flow Switches

Series FS4-3 switches are ideal for starting or stopping electrically operated equipment such as signal lights, alarms, motors, automatic burners, metering devices, and others.

Features:

- 1" NPT

- Two electrical knock-outs allow connection from either end

- Sensitivity adjusting screw makes flow adjustment easy

- Single pole, double throw snap switch

- Hardened stainless steel bearings minimize friction

- Sealed Monel bellows

- Four stainless steel paddles included: 1", 2", 3", and 6" (25, 50, 80, and 150mm)

- Minimum temperature (fluid or ambient): 32°F (0°C)

- Maximum temperature: 300°F (149°C)

- Maximum pressure: 160 psi (11.3 kg/cm2)

- Optional features:

- Two SPDT switches to make or break two separate circuits

- Materials of construction suitable for corrosive liquids

- BSPT threads

McDonnell & Miller Series FS4-3T General Purpose Liquid Flow Switches

Series FS4-3T general-purpose liquid flow switches are ideal for starting or stopping electrically operated equipment such as signal lights, alarms, motors, automatic burners, metering devices, and more.

Features:

- In-line configuration eliminates the need for a pipe tee

- Sizes available:

- 3/4" NPT

- 1" NPT

- Paddles available for low, medium, or high flow

- Two electrical knock-outs allow connection from either end

- Sensitivity adjusting screw makes flow adjustment easy

- Single pole, double throw snap switch

- Hardened stainless steel bearings minimize friction

- Sealed Monel bellows

- Minimum temperature (fluid or ambient): 32°F (0°C)

- Maximum temperature: 300°F (149°C)

- Maximum pressure: 160 psi (11.3 kg/cm2)

McDonnell & Miller Series FS5 General Purpose Liquid Flow Switches

Series FS5 switches are for general-purpose applications requiring low flow rate sensitivity.

Features:

- In-line configuration eliminates the need for a pipe tee

- Sizes available:

- 3/4" NPT

- 1" NPT

- Materials of construction:

- Models FS5 & FS5-D: brass, carbon, and EPDM elastomer (for water)

- Models FS5-S & FS5-DS: stainless steel, carbon, and Buna-N (for water or water and petroleum base compounds)

- Single pole, double throw snap switch

- Sensitivity adjusting screw makes flow adjustment easy

- Optional BSPT threads

- Minimum temperature (fluid or ambient): 32°F (0°C)

- Maximum temperature:

- 225°F (107°C) – stainless steel models

- 250°F (121°C) – brass

- Maximum operating pressure: 150 psi (10.5 kg/cm2)

McDonnell & Miller Series FS6 High Sensitivity Liquid Flow Switches

Series FS6 switches are ideal for heavy-duty applications requiring high sensitivity, such as water treatment systems, cooling systems for electronic circuits, compressors, booster pumps, and bearings, and other applications that need instant switching.

Features:

- In-line configuration eliminates the need for a pipe tee

- Very high flow capacity

- Actuates at an extremely low flow rate

- Sizes available:

- 3/4" NPT

- 1" NPT

- Single pole, double throw snap switch

- Switch compartment is completely sealed to protect it from the liquid

- Sensitivity adjusting screw makes flow adjustment easy

- Minimum temperature (fluid or ambient): 32°F (0°C)

- Maximum temperature: 225°F (107°C)

- Maximum operating pressure: 100 psi (7 kg/cm2)

- Optional BSPT threads

McDonnell & Miller Model FS6-W High Sensitivity Liquid Flow Switches

FS6-W switches are for heavy-duty applications with high sensitivity, such as water treatment systems, cooling systems for electronic circuits, compressors, booster pumps, bearings, and other applications that need instant switching.

Features:

- In-line configuration eliminates the need for a pipe tee

- Very high flow capacity

- Actuates at an extremely low flow rate

- Sizes available:

- 3/4" NPT

- 1" NPT

- Single pole, double throw snap switch

- Switch compartment is completely sealed to protect it from the liquid

- Sensitivity adjusting screw makes flow adjustment easy

- Minimum temperature (fluid or ambient): 32°F (0°C)

- Maximum temperature: 225°F (107°C)

- Maximum operating pressure: 100 psi (7 kg/cm2)

- BSPT threads are optional

McDonnell & Miller Series FS7-4 Industrial Liquid Flow Switches

Universal design serves the widest variety of large pipe applications, including heating and hydronic systems, air conditioning, refrigeration, and process work.

Features:

- 1-1/4" NPT

- Brass with sealed tube construction

- Single pole, double throw snap switch

- Magnetic switching mechanism eliminates the need for bellows

- Sensitivity adjusting screw makes flow adjustment easy

- Paddles can be trimmed to suit application needs

- Minimum temperature (fluid or ambient): 32°F (0°C)

- Maximum temperature: 300°F (149°C)

- Maximum operating pressure:

- 300 psi (21 kg/cm2)

- 1000 psi (70 kg/cm2) – stainless steel models

Optional Features:

- Extended paddle arm – model FS7-4L

- Two SPDT switches to make or break two separate circuits

- Stainless steel body and paddles

- BSPT threads

McDonnell & Miller Series FS7-4E Industrial Liquid Flow Switches

Series FS7-4E switches are for hazardous environment applications requiring a NEMA 7 (Class I, Group C or D) or NEMA 9 Class II, Group E, F, or G) rated flow switch.

Features:

- 1-1/4" NPT

- Brass with sealed tube construction

- Single pole, double throw snap switch

- Magnetic switching mechanism

- Sensitivity adjusting screw makes flow adjustment easy

- Paddles can be trimmed to suit application needs

- Minimum temperature (fluid or ambient): 32°F (0°C)

- Maximum temperature: 300°F (149°C)

-

- Maximum operating pressure:

- 300 psi (21 kg/cm2)

- 1000 psi (70 kg/cm2) – stainless steel models

- Optional features:

- Extended paddle arm

- Stainless steel body and paddles

- BSPT threads

McDonnell & Miller Series FS7-4W Industrial Liquid Flow Switches

1-1/4" NPT Series FS7-4W switches are ideal for applications requiring a water-tight, dust-tight, or NEMA 4X-rated flow switch.

Features:

- Brass with sealed tube construction

- Single pole, double throw snap switch

- Magnetic switching mechanism eliminates need for bellows

- Sensitivity adjusting screw makes flow adjustment easy

- Paddles can be trimmed to suit application needs

- Minimum temperature (fluid or ambient): -65°F (-54°C)

- Maximum temperature: 300°F (149°C)

- Maximum operating pressure:

- 300 psi (21 kg/cm2)

- 1000 psi (70 kg/cm2) – stainless steel models

- Optional features:

- Extended paddle arm

- Stainless steel body and paddles

- BSPT threads

McDonnell & Miller Series FS8-W General Purpose Liquid Flow Switches

Series FS8-W liquid flow switches are for general-purpose applications with environmental exposure or require a water-tight, dust-tight, or NEMA 4X rated flow switch 1″ NPT.

Features:

- Sealed Monel bellows

- Single pole, double throw snap switch

- Four stainless steel paddles included – 1", 2", 3", and 6" (25, 50, 80, and 150mm)

- Sensitivity adjusting screw makes flow adjustment easy

- Minimum temperature (fluid or ambient): 32°F (0°C)

- Maximum temperature: 225°F (107°C)

- Maximum operating pressure: 160 psi (11.3 kg/cm2)

- Optional features:

- BSPT threads

- Gold-plated contacts

Shop McDonnell & Miller Liquid Flow Switches

McDonnell & Miller Flow Switch Catalog

McDonnell & Miller Series AF1 Air Flow Switches

Series AF1 air flow switches are for general-purpose applications with medium and high-velocity requirements.

Features:

- Paddle fits 8" (203mm) minimum duct size or 6" (152mm) if trimmed

- Brass, steel, and aluminum construction

- Single pole, double throw snap switch

- Sensitivity adjusting screw makes flow adjustment easy

- Two electrical knock-outs allow connection from either end

- Can be equipped with a time delay relay

- Optional features: stainless steel

- Minimum ambient temperature: 32°F (0°C)

- Maximum duct temperature: 300°F (149°C)

McDonnell & Miller Series AF2 Air Flow Switches

Series AF2 air flow switches are ideal for low-velocity applications.

Features:

- Paddle fits 8" (203mm) minimum duct size

- Two electrical knock-outs allow connection from either end

- Brass, steel, and aluminum construction

- Single pole, double throw snap switch

- Sensitivity adjusting screw makes flow adjustment easy

- Can be equipped with a time delay relay

- Minimum ambient temperature: 32°F (0°C)

- Maximum duct temperature: 300°F (149°C)

McDonnell & Miller Series AFE-1 Air Flow Switches

Series AFE-1 air flow switches are ideal for industrial hazardous environment applications requiring a NEMA 7 (Class I, Division I, Group C, and D) or NEMA 9 (Class II, Division I, Group E, F, and G) rated flow switch for medium velocity.

Features:

- 1/2" NPT conduit connection

- Paddle fits 8" (203mm) minimum duct size

- Brass, steel, and aluminum construction

- Single pole, double throw snap switch

- Magnetic switching mechanism eliminates the need for bellows

- Sensitivity adjusting screw makes flow adjustment easy

- Maximum ambient temperature: 120°F (49°C)

- Maximum duct temperature: 275°F (135°C)

McDonnell & Miller Series AF3 Air Flow Switches

Series AF3 air flow switches are ideal for general-purpose low-velocity applications.

Features:

- Paddle fits 8" (203mm) minimum duct size

- Two electrical knock-outs allow connection from either end

- Brass, steel, and aluminum construction

- Single pole, double throw snap switch

- Sensitivity adjusting screw makes flow adjustment easy

- Can be equipped with a time delay relay

- Two SPDT snap switches are optional

- Minimum ambient temperature: 32°F (0°C)

- Maximum duct temperature: 275°F (135°C)

Shop McDonnell & Miller Air Flow Switches

McDonnell & Miller Flow Switch Catalog

Installation & Maintenance of McDonnell & Miller Flow Switches

Proper installation and regular maintenance are critical for the efficient and reliable operation of McDonnell & Miller flow switches. By following these steps for installation and maintenance, you can ensure the longevity and reliable performance of your McDonnell & Miller Flow Switch. Always refer to the product manual for detailed instructions and safety guidelines.

Installation

- Select the Right Location – Choose an installation location that offers easy accessibility for future maintenance. The flow switch should be installed in a straight section of the pipe to ensure an accurate flow reading.

- Install in the Correct Orientation – The orientation of the flow switch largely depends on its design. Some models are intended for horizontal installation, while others can be installed vertically. Refer to the product manual for specific guidelines.

- Secure the Flow Switch – Once you've selected the installation location and determined the correct orientation, secure the flow switch in place. This usually involves inserting the flow switch into the pipeline and securing it with suitable fixtures.

- Connect to Control System – After the physical installation, connect the flow switch to the control system by wiring the switch to the control panel according to the wiring diagram in the product manual.

Consult the McDonnell & Miller Flow Switch Catalog for more information on specific installation methods.

Maintenance

- Regular Inspection – Regularly inspect the flow switch for signs of wear and tear. Check for any signs of corrosion or physical damage that could impact its operation.

- Clean the Flow Switch – Over time, debris or sediments may build up in the flow switch, affecting its operation. Regularly clean the switch to prevent blockages. Make sure to shut down the system and follow safety procedures during cleaning.

- Check the Mechanical Parts – Regularly check the moving parts of the flow switch, such as the paddle or vane, for any signs of damage or wear. Damaged parts should be replaced promptly to ensure proper operation.

- Test the Switch – Regularly test the switch to ensure it operates correctly. This can typically be done by observing the switch's response to changes in fluid flow.

McDonnell & Miller Flow Switch FAQs

Can McDonnell & Miller flow switches be used with any fluid?

While McDonnell & Miller flow switches are versatile, the specific type of fluid a particular model can handle depends on its design. Some models are intended for liquids, others for gases, and still others for steam. Always check the product specifications to ensure the switch suits your specific application.

How do I adjust the setpoint on my McDonnell & Miller flow switch?

The process for adjusting the setpoint may vary depending on the specific model of your McDonnell & Miller flow switch. Some models may have a dial or screw that can be adjusted, while others might require a different procedure.

Can I use my McDonnell & Miller flow switch in high-temperature applications?

McDonnell & Miller offers several flow switch models that are designed to withstand a wide range of temperatures, making them suitable for various applications. However, it is crucial to check the temperature range specified in the product documentation to ensure it is suitable for your application.

What materials are McDonnell & Miller flow switches made of?

The materials used to construct McDonnell & Miller flow switches depend on the specific model and application. Common materials include brass, stainless steel, and other corrosion-resistant compounds for enhanced durability and longevity.

Can I replace parts of my McDonnell & Miller flow switch, or do I need to replace the entire unit?

In many cases, parts such as the paddle or vane can be replaced without replacing the entire unit. However, replacing the entire flow switch might be more cost-effective or necessary if the damage or wear is extensive.

How do I calibrate my McDonnell & Miller flow switch?

Calibration procedures can vary depending on the specific model of your flow switch. Some models may have a built-in calibration process, while others might require external calibration equipment.