Taco Air Separators are an integral part of many HVAC systems, working to ensure optimal performance by effectively eliminating air from the system. They offer a range of benefits that can significantly enhance the efficiency and longevity of heating and cooling systems.

How Do Taco Air Separators Work?

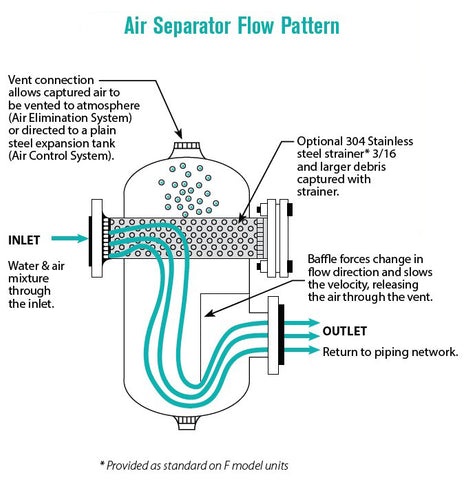

Taco Air Separators are specially engineered for efficient and long-lasting operation in HVAC systems. These devices work on a simple yet highly effective principle: air, being lighter than water, rises naturally. Taco Air Separators capitalize on this principle, providing a method to trap and remove this air from the system.

The mechanism inside a Taco Air Separator is relatively simple. It uses a patented design called the PALL ring process. These PALL rings are metal structures within the device that increase the surface area for air to separate from the fluid more efficiently.

As water or coolant enters the air separator, it hits the PALL rings, breaking up the fluid and allowing trapped air bubbles to rise. The fluid moving around these rings creates a centrifugal force, driving out any entrapped air. The lighter air is then pushed to the top of the air separator, where it collects into an air vent assembly.

The air vent assembly comprises a float mechanism. As the air accumulates, the float drops, which opens the vent and allows the air to escape. Once the air is expelled, the float rises, closing the vent, and the process begins again. This cyclical process continually purges air from the system, maintaining a high level of efficiency in the heating or cooling system.

Taco Air Separators operate through centrifugal force, buoyancy, and the unique PALL ring process to consistently and effectively remove air from the heating or cooling system. This process helps to prevent system corrosion, increases efficiency, and reduces noise, making it a valuable addition to any HVAC setup.

Advantages of Taco Air Separators

There are several key advantages of using Taco Air Separators in HVAC systems. These include:

- Improved System Efficiency: Taco Air Separators can increase system efficiency by removing air bubbles that could inhibit fluid flow, leading to more consistent heating and cooling.

- Prevention of Corrosion: By removing oxygen from the system fluid, these air separators can significantly reduce the risk of corrosion, extending your HVAC system's lifespan.

- Reduced Noise: Air in the system can lead to annoying noises during operation. Taco Air Separators can help mitigate these noises by removing the air from the system.

Taco Air Separators Installation

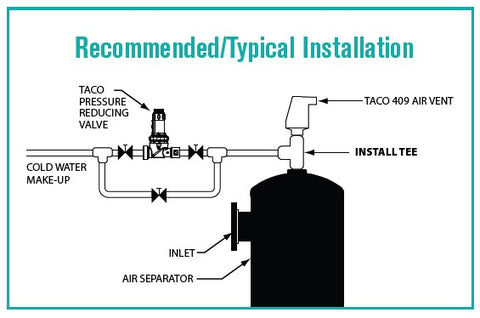

Every HVAC system might have unique features or requirements, so always refer to the manufacturer's installation instructions before proceeding. Generally, installation of Taco Air Separators includes several steps:

- System Assessment: Before starting the installation process, you must assess your HVAC system to decide the optimal placement for the Taco Air Separator. Ideally, it should be installed on the supply side of the system and after the heat source for maximum efficiency. The separator size should be the same as the pipe size in your HVAC system.

- Preparation: After the initial assessment, the area where you plan to install the air separator should be cleaned and cleared. Ensure you have the necessary tools on hand to conduct the installation. This might include wrenches, pipe cutters, and safety gear like gloves and goggles. Make sure to switch off the HVAC system before beginning installation for safety.

- Installation: The Taco Air Separator should be installed upright and in a vertical pipe run. It's crucial to ensure that the arrow on the separator matches the direction of fluid flow in the system. Secure the air separator using appropriate fittings after cutting the pipe at the designated installation point. Be careful to tighten the fittings securely, but not overly tight, to prevent any possible leakage.

- Finishing Up: Once the Taco Air Separator is installed, reconnect the system and switch the power back on. Check for any leaks around the separator and monitor the system during its initial run to ensure it works properly.

- Verification: It's crucial to ensure the Taco Air Separator functions correctly post-installation. Keep an eye out for any signs of air build-up or noises from the HVAC system that might suggest the separator is not working as intended. If any issues are noted, consult the manufacturer's manual or a professional for troubleshooting advice.

Maintaining Taco Air Separators

Regular inspection is the first and most important aspect of maintaining your Taco Air Separator. Inspect the unit for any signs of leaks, corrosion, or other visible damage routinely. Check the air vent and ensure it's not blocked or damaged; this is an essential separator component.

Depending on the specific model and your system's condition, your Taco Air Separator may require periodic cleaning, which typically involves disassembling the unit and cleaning out sediment or mineral build-up.

Unusual noises coming from the HVAC system could indicate air build-up, suggesting the separator is not functioning correctly. If you notice any changes in your system's performance, such as a reduction in heating or cooling effectiveness, this may also be a sign that the separator needs attention.

The automatic air vent on top of the Taco Air Separator can accumulate mineral deposits over time. The vent should be cleaned or replaced if it seems clogged or not functioning properly. Always turn off your HVAC system and follow the manufacturer's instructions when performing this task.

If you find worn-out or damaged parts during any of your inspections, these should be replaced as soon as possible. Using a faulty air separator can decrease the efficiency of your HVAC system and possibly lead to more severe issues in the future.

While routine personal inspection and maintenance are essential, having your HVAC system professionally inspected annually is also recommended. A trained professional can detect and troubleshoot any issues that you might have missed.

Proper maintenance is key to extending the life of your Taco Air Separator and keeping your HVAC system running efficiently. Always refer to the manufacturer's guidelines for specific maintenance tips and instructions.

Taco Air Separator Models

4900 Series Bronze Air Separators

Taco 4900 Series Bronze Air Separators eliminate air from closed-loop heating and cooling systems up to a maximum temperature of 240°F and a maximum pressure of 150 psi. 4900 Series air separators feature a PALL ring process to remove gases from water. The ultimate micro-bubble separation of the PALL ring process eliminates the damaging effects and irritating noise caused by unwanted system air.

4900 Series Commercial Air & Dirt Separators

Taco 4900 Series Commercial Air & Dirt Separators save money and prolong the life of system pumps, piping, and components by removing air, dirt, and other contaminants from the system to prevent problems such as reduced heat transfer, loss of efficiency, pipe corrosion, pump damage, and more.

Using Taco's patented PALL ring technology, 4900 Series separators use coalescence to collect and merge micro-bubbles, allowing them to vent through the integral vent mechanism at the top of the vessel. The PALL Ring stops the dirt particles' momentum, allowing them to fall to the bottom of the vessel and be blown down by the integral full port blow down valve. The optional on/off magnet uses a high-powered neodymium magnet assembly to collect black iron oxide and magnetite. This unique feature of energizing the magnet with the flip of a handle allows easy maintenance, reducing the time and effort required to collect and flush magnetite from the system. These are great for systems with variable speed, ECM, and constant flow requirements.

5900 Series FlexBalance Air Separators

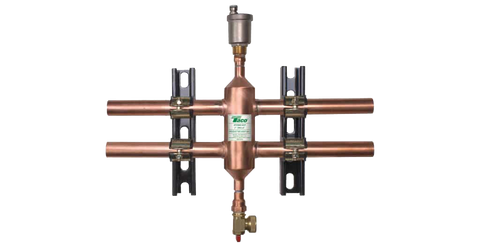

Taco 5900 Series FlexBalance Air Separators act as a hydraulic bridge between primary and secondary heating and cooling applications to provide improved system energy efficiency and allow the use of smaller pumps for each system circuit. The 5900 Series FlexBalance Air Separator helps prevent hydraulic coupling of pumps or pumps in series by primary/secondary configurations and prevent unanticipated ghost-flows caused by oversized pumps in primary and secondary circuits. They are available with optional 304SS PALL Ring basket configurations to enhance the air and dirt separation capabilities of the 5900. 5900 Series FlexBalance Air Separator Tanks are designed, constructed, and tested to ASME Section VIII, Div. 1 requirements.

AC/ACF Series In-Line Air Separators

Through its internal baffle design, Taco AC/ACF Series In-Line Air Separators work great in ether constant and variable flow systems. AC/ACF Series In-Line Air Separator tanks are designed, constructed, and tested to ASME Section VIII, Div. 1 requirements.

ACT Series Tangential Air Separators

Taco ACT Series Tangential Air Separators feature a highly efficient tangential design that helps clear the system of free air and reduces un-dissolved sediment to save money, energy, and component wear. Taco ACT Series Tangential Air Separators Tanks are designed, constructed, and tested to ASME Section VIII, Div. 1 requirements.

Air Scoops

The unique design and internal baffles of Taco Air Scoops slow water velocity to separate the air from the solution. This design allows Taco Air Scoops to remove air to provide noiseless, air-free hydronic heating, cooling, or combination systems. They also offer an economical way to integrate air elimination by connecting a plain steel or diaphragm expansion tank. Air Scoop features include:

- A one-piece cast iron construction

- Engineered baffle to separate air from water

- Maximum operating pressure of 125 psi (862 kPa)

- Maximum operating temperature of 300°F (135°C)

Hydro-Sep Hydraulic Separators

Taco's Hydro-Sep Hydraulic Separators are compact, economical units that allow fast and efficient installation of primary/secondary piping for many different boilers. Installing this unique hydraulic separator offers the additional advantage of assisting in removing unwanted air and dirt particles, preventing their damaging effects on system components. It is especially suitable for today's smaller boilers that tend to have a much higher flow resistance.

In Conclusion

Taco Air Separators can play a vital role in maintaining the efficiency and longevity of your HVAC system. By understanding their function and advantages, as well as the installation and maintenance process, you can make the most of these devices in your heating and cooling systems.