A damper actuator, also known as a damper motor, is a device used to control the opening and closing of a damper in HVAC and industrial systems. They are essential to regulating airflow within various ducts and ventilation systems.

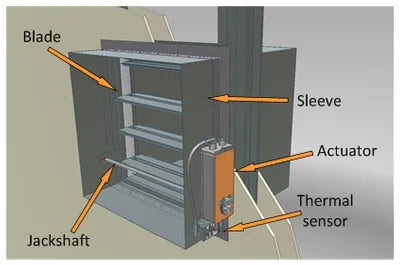

A damper is a plate or gate that can be opened or closed to control airflow or other gases. The actuator is the component that provides the necessary force to move the damper, enabling precise control over airflow. It can be driven by electric, pneumatic, or hydraulic power, depending on the specific application and requirements.

In HVAC systems, damper actuators help control temperature and air quality by regulating the amount of air that flows through the system. By adjusting the damper's position, the system can control the mixture of fresh and recycled air, maintain the desired temperature, and even control humidity.

Damper actuators are also used in industrial applications, such as in flue gas systems, where they control the flow of exhaust gases. By using damper actuators, operators can control the rate and direction of flow, which can be vital for safety, efficiency, and compliance with environmental regulations.

How Does a Damper Actuator Work?

A damper actuator receives a signal from a control system, which represents a desired position for the damper, often in response to conditions such as temperature settings or airflow needs. The internal control system inside the actuator translates this signal into a specific action, like opening or closing the damper.

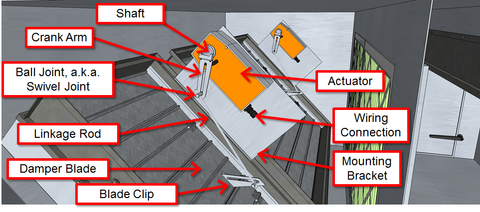

Upon receiving the instruction, the actuator's motor activates. This motor can be electric, pneumatic, or hydraulic, and its role is to provide the necessary force to move the damper. In many actuators, a gear train is used to convert the motor's output into the proper form of movement needed to control the damper, possibly altering the speed or torque of the motion.

This movement is then transferred to the damper via a shaft and linkage, leading to the damper opening or closing to control the flow of air or gas. Many damper actuators also include a feedback mechanism, often utilizing sensors that continually monitor the damper's position and send the information back to the control system. This ensures the damper is correctly positioned.

The actuator continues to monitor signals from the control system and the position of the damper, making necessary adjustments to keep the damper in the correct position even as conditions change. Suppose there's a need for manual intervention. In that case, some damper actuators have a manual override function, allowing an operator to manually open or close the damper, bypassing the automatic control.

Safety features are often incorporated into the damper actuator's design to prevent potential damage or ensure proper functioning in case of a system failure. These include mechanisms like limit switches to prevent over-rotation or fail-safe features to move the damper to a safe position if the control signal is lost.

By precisely controlling the damper's position, a damper actuator plays a vital role in HVAC systems and industrial applications, maintaining the correct temperature, humidity, and air quality or controlling the flow of gases. While there may be variations in the operation depending on the type of actuator (electric, pneumatic, hydraulic), these general principles apply across different designs.

Types of Damper Actuators

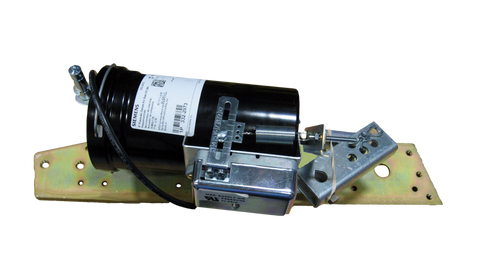

Electric Damper Actuators

Electric damper actuators use an electric motor to control the opening and closing of a damper. The operation of an electric damper actuator begins with receiving a control signal that corresponds to a desired damper position. The electric motor within the actuator responds by generating a rotational force. A gear train is often used to convert this rotational force into a form suitable for moving the damper to the specified position. This process allows precise control over the damper's position, enabling accurate airflow or gas flow regulation.

One of the main advantages of electric damper actuators is their precision and ease of integration with digital control systems. They offer high reliability and can be energy-efficient, as they typically consume power only when changing positions. However, they are dependent on a consistent electric power supply and might require cooling mechanisms to manage heat generated by the electric motor. Commonly found in modern HVAC systems and various industrial processes, electric damper actuators are vital in maintaining desired environmental conditions and controlling gas flows. Their versatility and precise control make them a preferred choice in many settings.

Pneumatic Damper Actuators

Compressed air acts as the motive force in a pneumatic damper actuator. When the actuator receives a control signal, it directs the compressed air to a piston or diaphragm inside a cylinder. The pressure of the air causes the piston or diaphragm to move, and this movement is then transferred to the damper, causing it to open or close. The amount of air pressure can be modulated to control the damper's position precisely.

One of the significant advantages of pneumatic damper actuators is their robustness and suitability for harsh environments where electric components might not be ideal. They are often more straightforward in design, which can lead to increased durability. However, they require a source of compressed air, which means the system must include air compressors, filters, and other related components.

Pneumatic damper actuators are commonly used in large industrial settings where the necessary compressed air systems are already in place. They might be preferred in applications that require substantial force or where the environment may be too harsh for electric components. Their use of compressed air as a power source, rather than electricity, can also make them an attractive option in certain safety-critical applications where avoiding sparks is essential.

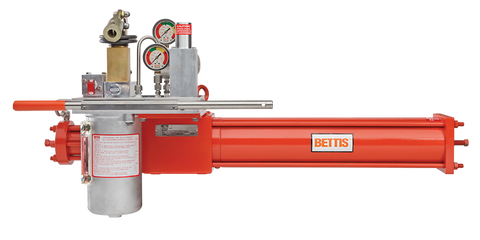

Hydraulic Damper Actuators

In a hydraulic damper actuator, a hydraulic pump pressurizes fluid within a closed system, creating a force that can be used to move a piston or other mechanical components. When a control signal is received, corresponding valves within the actuator are opened or closed, directing the pressurized fluid to move the piston. This movement is then translated to the damper, causing it to open or close, and the damper's position can be modulated by controlling the flow and pressure of the hydraulic fluid.

One of the main advantages of hydraulic damper actuators is their ability to deliver high force and withstand harsh operating conditions, making them suitable for heavy industrial applications or where substantial force is required. Additionally, hydraulic systems can offer smooth and precise control over movement, allowing for accurate positioning of the damper.

However, hydraulic damper actuators can be more complex. They may require regular maintenance to ensure the hydraulic fluid is clean and the seals and other components are in good condition. They are typically more expensive and might be less energy-efficient than electric or pneumatic options. Moreover, potential leaks in the hydraulic system can lead to environmental concerns and operational challenges.

Read more about Actuators for HVAC Applications

Damper Actuator Maintenance & Troubleshooting Tips

Maintenance and troubleshooting of damper actuators are essential for ensuring their continued optimal performance and longevity. Always refer to the manufacturer's maintenance manual, which will contain specific information tailored to the exact model and type.

Maintenance Tips

- Periodically inspect the actuator for wear, corrosion, leaks, or damage. Check all mechanical linkages, seals, and electrical connections.

- Depending on the type and usage, lubricate the moving parts as the manufacturer recommends.

- Periodically calibrate the actuator to ensure it's accurately responding to control signals. This may include checking feedback sensors and alignment.

- Regularly check and replace filters and ensure the fluid or air is clean and at the proper pressure for hydraulic and pneumatic actuators.

- If the actuator has fail-safe or emergency features, test them regularly to ensure they function correctly.

Troubleshooting Tips

- Damper Not Moving Correctly: If the damper is not moving to the desired position, check for mechanical obstructions, misalignment, or issues with the control signal.

- Noise or Vibrations: Unusual noises or vibrations may indicate wear or misalignment. Inspect for worn parts, loose connections, or other mechanical issues.

- Leakage in Hydraulic or Pneumatic Systems: If there's a leak, inspect all seals, hoses, and connections. Replace any damaged components as needed.

- Motor or Pump Failure: Test the motor or pump for electric or hydraulic actuators and replace or repair as necessary. Check electrical connections for corrosion or damage.

- Inconsistent Operation: If the actuator behaves inconsistently, it may be an issue with the control system or feedback mechanisms. Carefully inspect and test these components.

- Environmental Factors: Consider environmental factors such as temperature, humidity, or corrosive substances that might affect the performance. Ensure the actuator is suitable for the operating conditions.

- Utilize Diagnostic Tools: Many modern actuators come with built-in diagnostics. Utilize these tools to pinpoint issues and refer to the troubleshooting guide provided by the manufacturer.

This video from Belimo provides basic actuator troubleshooting tips and tricks:

Damper Actuator Selection

Choosing the right damper actuator is a critical decision that depends on several factors related to the specific application, operating conditions, and requirements.

- Understand the Application: Determine the primary function of the damper actuator within the system. Is it for regulating temperature, controlling air quality, safety purposes, or something else? The application will guide many of the following considerations.

- Select the Type of Actuator: Depending on the needs and environment, you might choose an electric, pneumatic, or hydraulic actuator. Electric actuators are often preferred for their precision, pneumatic actuators for robustness, and hydraulic actuators for delivering high force.

- Determine the Torque Requirements: The torque required to move the damper must be carefully calculated. It should consider friction, air pressure, damper size, and other variables. The actuator must provide sufficient torque to handle the load.

- Consider the Control System: Consider how the actuator will be controlled and ensure it is compatible with the existing or planned control system. Modern actuators often allow for integration with digital control systems, offering more precision and functionality.

- Evaluate the Environment: Assess the operating conditions, such as temperature, humidity, potential exposure to corrosive substances, etc. The actuator should be designed to withstand these conditions without degradation.

- Analyze the Power Source: Ensure that the chosen actuator is compatible with the available power source, whether an electrical supply, compressed air system, or hydraulic fluid.

- Look for Safety Features: Depending on the application, you may need specific safety features, such as fail-safe mechanisms that move the damper to a safe position in case of power loss or system failure.

- Consider Maintenance Needs: Evaluate the ease of maintenance and the expected maintenance schedule. Some actuators may require more frequent attention, affecting long-term costs and system uptime.

- Review Regulatory Compliance: Ensure the actuator complies with applicable standards, codes, or regulations specific to your industry or region.

- Budget Considerations: Assess the total cost of ownership, including initial purchase, installation, maintenance, and energy consumption. Spending more upfront on a higher-quality or more efficient actuator may save money in the long run.

- Consult Manufacturer or Distributor: Engaging with a knowledgeable manufacturer or distributor who understands your specific needs can be invaluable. They can provide guidance based on experience with similar applications and ensure you select the right product.

- Consider Future Needs: Think about scalability and future needs of the system. Choosing an actuator with additional capacity or features might offer flexibility for future changes or upgrades.

By carefully considering these factors and working closely with manufacturers or experienced professionals, you can select the damper actuator that best fits your specific application, budget, and long-term needs. It may also be beneficial to reference any industry-specific guides or standards that pertain to damper actuators in your field.

This webinar from Belimo covers the 10 steps for sizing and selecting damper actuators: