A flame sensor is a safety device used in gas-burning furnaces and boilers to detect the presence of a flame. If the system is running (gas is being released), but no flame is detected, it could lead to a dangerous buildup of unburned gas. The flame sensor's role is to confirm the existence of a flame when there should be one. If the flame goes out unexpectedly or doesn't ignite when it should, the sensor signals the control board, which shuts off the gas supply to prevent an unsafe condition.

How Does a Flame Sensor Work?

Flame sensors are typically made of a conductive metal, like stainless steel or sometimes a metal rod coated in porcelain, and are positioned in the path of the burner flame. When the burner is ignited, the flame makes contact with the sensor.

Flames possess a unique property called "flame rectification," which allows them to act as conductors for electricity. This means that the flame's presence can generate a microamp-level electrical signal. The flame sensor detects this signal and communicates to the control board of the appliance. If the control board doesn't receive this microamp signal, it interprets the lack of signal as an absence of flame, prompting it to shut off the gas supply as a safety measure.

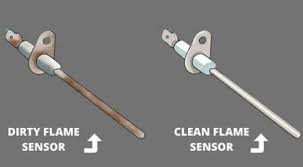

Over time, the sensor can get coated with soot or other contaminants, which might affect its ability to detect the flame correctly. Therefore, periodic cleaning and maintenance are essential to ensure its proper functioning.

Types of Flame Sensors

Flame Rectification Sensor (Flame Rods)

A flame rod, or flame rectification sensor, is a safety device used in gas-burning appliances to detect the presence of a flame. Positioned within or near the flame's path, this metallic rod relies on the ionization property of fire. When a flame touches the rod, it generates a microampere-level electrical current, signaling the presence of the flame to the control system. If this current is absent, the system deduces there is no flame and consequently shuts off the fuel supply as a safety measure, preventing unburned gas accumulation and potential hazards. Regular maintenance is essential to keep the rod functioning optimally and free from contaminants.

Ultraviolet (UV) Flame Detectors

Most flames emit UV radiation, which can be detected almost instantaneously, making UV detectors quick to respond. They are, however, more susceptible to false alarms from other UV sources, like arc welding or lightning.

Infrared (IR) Flame Detectors

Flames emit infrared radiation due to the hot gases produced. Infrared detectors can identify these emissions, and some advanced models can even discriminate between flames and other IR sources based on the specific wavelength of the radiation. These detectors can be particularly useful in situations where visibility is reduced, like in the presence of heavy smoke. UV and IR flame detection can be combined into a single unit to cover a wide range of applications.

Visible Light (Video) Flame Detectors

Visible light flame sensors use video analytics to analyze visible light patterns and colors associated with flames. Advanced algorithms can differentiate between actual flames and false alarms, such as sunlight reflections or artificial lights.

Thermal (Heat) Detectors

While not exclusively flame sensors, these devices detect a rapid rise in temperature indicative of a fire. They are slower in response than other flame sensors but can be helpful in environments where different types of detectors might be prone to false alarms.

Ionization Flame Detectors

These sensors work on the flame rectification principle, where the flame acts as a rectifier, allowing current to flow in one direction. This principle is common in many household gas-burning appliances.

Acoustic Flame Detectors

These detectors identify the unique ultrasonic acoustic signatures produced by flames, especially in high-pressure environments.

How to Properly Clean a Flame Sensor

Cleaning a flame sensor is a relatively simple process, but doing it carefully and correctly is crucial to ensure the sensor's functionality isn't compromised. Here's a step-by-step guide on how to clean a flame sensor:

- Turn Off Power: Before starting any work, ensure the power to the furnace or appliance is turned off for safety.

- Locate the Flame Sensor: Open the furnace or appliance access panel. The flame sensor is typically found near the burners. It looks like a thin metal rod sticking out into the path of the flames.

- Remove the Flame Sensor: The flame sensor is usually held in place by one or two screws. Carefully remove these screws and gently pull out the sensor using a screwdriver.

- Clean the Sensor: Gently scrub the sensor's rod using a fine abrasive pad, like steel wool or an emery cloth. Be careful not to apply too much pressure; you only want to remove the buildup without damaging the rod. Avoid using chemical cleaners, as these might leave a residue that could affect the sensor's operation.

- Reinstall the Flame Sensor: Once cleaned, reposition the flame sensor back in its original location and secure it using the screws you removed earlier.

- Restore Power: Close the access panel and turn the power back on to the appliance.

- Test the Furnace or Appliance: After cleaning, it's a good idea to test the appliance to ensure it's functioning correctly. Turn it on and observe if it ignites and operates as expected.

Regular maintenance, including periodic cleaning of the flame sensor, can extend the life of your appliance and ensure it operates safely and efficiently.

Shop Flame Sensors

We offer a variety of flame sensors from manufacturers such as Trane, Carrier, York, and more. Can't find the one you need? Call or email one of our specialists for assistance.