Flow control valves regulate the flow or pressure of a fluid. Flow control valves are used in commercial and residential hydronic heating systems to limit water flow to equipment. Control of flow in hydronic systems is critical because the rate of movement of fluid-powered machines or actuators depends on the pressurized fluid's flow rate.

Flow control valves can be installed in either a vertical or horizontal position. Either location requires the valve to be installed with the arrow on the valve body facing the flow direction. When the circulator is operating, water passes through the flow control valve. When the circulator stops, the flow control valve remains closed and blocks the gravity flow of the water. Flow control valves do not typically require service or maintenance. However, a defective flow control valve must be replaced.

Types of Flow Control Valves

Flow control valves are available in many different types, but the most common are:

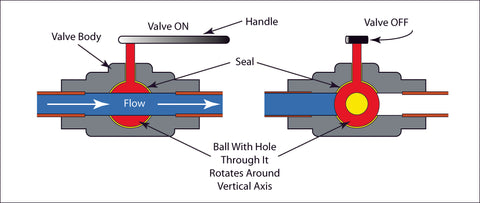

Ball Valves

Ball valves are shutoff valves that use a ball to stop or start the flow of fluid downstream of the valve. Ball valves are recommended for fully open/closed and modulating applications.

The advantages of ball valves include relatively low cost, high flow capacity, tight sealing with low torque, and high close-off pressure. Disadvantages include inherent dead bands.

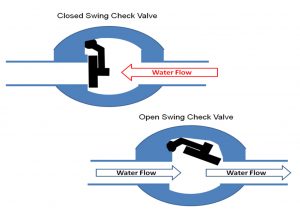

Check Valves

Check valves permit flow in only one direction, preventing the reversal of fluid flow in piping. They remain open by the force of the flowing fluid. If the fluid is reversed, the valve will close.

Butterfly Valves

Butterfly valves are recommended for fully open/closed applications, throttling applications, and small pressure drop applications. They are commonly used because they are lightweight, easy to operate, inexpensive, self-cleaning, have a high flow capacity and have a relatively low pressure drop across the valve when it’s open. However, butterfly valves have high torque requirements for control and low flow cavitation risk.

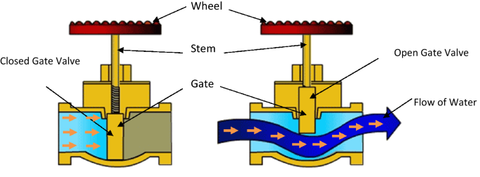

Gate Valves

Gate valves are ideal as isolating or stop valves, where full flow or no flow is required. When a gate valve is fully opened, the fluid will flow in a straight line, and there isn’t a significant drop in pressure because of low resistance to flow.

Gate valves are also often used when a straight-line fluid flow and minimum flow restriction are needed. Gate valves use a sliding plate within the valve body to stop, limit, or permit the full flow of fluids.

Gate valves are not suitable for throttling volume. The control of flow is difficult because the valve’s design and the flow of fluid slapping against a partially open gate can cause extensive damage to the valve.

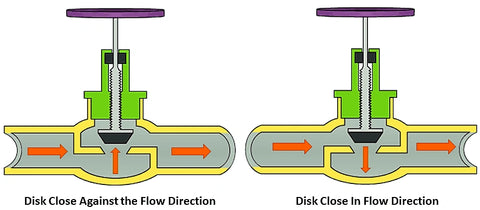

Globe Valves

Globe valves are recommended for applications that require precise flow regulation, frequent and wide throttling, and high-pressure drops. Globe valves are suited for water and steam. They have efficient and precise throttling as well as highly accurate flow control. However, they have relatively low flow coefficients and generally cost more than other valves. Globe valves feature a unique construction designed to make the fluid passing through change direction twice.

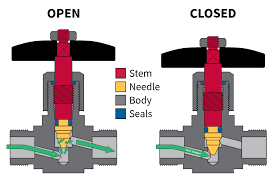

Needle Valves

Needle valves offer precise control of flow. They feature a sharply pointed disc and a matching seat. Although needle valves can control flow with precision, they are usually capable of handling only relatively low flow rates.

Flow Control Valves by Manufacturer

NIBCO FLO-BOSS Valves

NIBCO FLO-BOSS valves and connectors keep indoor spaces comfortable and energy efficient. NIBCO balancing and control valves – including automatic, manual, lead-free, and press ends – work with heating, cooling, or water distribution systems to deliver optimum performance and trouble-free maintenance.

Bell & Gossett Flo-Control Valves

Flow control valves from Bell & Gossett offer optimized system efficiency that reduces energy and operating costs while increasing comfort and field adjustability for precise control when and where you need it. They control flow independent of fluctuating system pressures (pressure-independent valves only) and have a broad product range and sizes (1/2"-20"), providing a solution to fit any system needs. In addition, complete coil hook-up kits are available for ease of installation and serviceability.

Bell & Gossett Flo-Control valves prevent gravity flow in forced water systems and permit year-round operation of indirect water heaters. 3/4" to 2" NPT Flo-Control valves have a combination straight/angle pattern, which enables installation in either horizontal or vertical pipelines. Larger size Flo-Control valves may have either straight or angle patterns. A removeable top cap allows easy cleaning and service without removing pipe connections. Manual operating position for vertical lift disc to permit gravity circulation.

Shop Bell & Gossett Flo-Control Valves

Taco Flo-Chek Valves

Taco Flo-Chek valves prevent “gravity” circulation in forced hot water heating systems. Flo-Chek valves open automatically when the circulator starts running and can be used in systems with multiple circulator zones to allow heat to flow only into the zones calling for heat. In addition, the thumb screw can be opened manually for gravity feed applications if the primary circulator stops operating. They have a 125 psi maximum operating pressure (862 kPa) and 277°F maximum operating temperature (136°C).