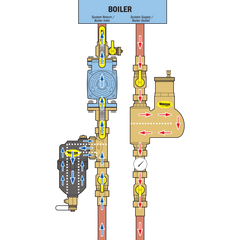

Magnetic boiler filters protect a boiler from iron sludge that can accumulate in a hydronic system. When installed on the system return line, a magnetic boiler filter captures ferrous debris before reaching the boiler using a magnet and plastic or metal filter. Models with gravity filter designs can remove non-ferrous debris.

Purpose of a Magnetic Boiler Filter

Rust and corrosion can form in pipes over time, and the subsequent residue will peel off and combine with other debris to create a sludge-like substance. This sludge can cause blockages and other issues on the system, causing it to work less efficiently and potentially causing breakdowns. A magnetic filter collects debris and prevents build-up in a heating system, allowing water to continue flowing through the system as usual and can keep a system as cost-efficient as possible for longer.

How Magnetic Boiler Filters Work

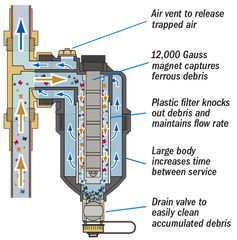

Magnetic filters attract corroded metals to prevent them from building up in the system. A magnet captures ferrous debris, while a metal or plastic mesh filters out non-ferrous debris and maintains the system flow rate. An air vent on top of the filter allows trapped air to release. A drain valve on the bottom of the filter allows a technician to clean out accumulated debris easily.

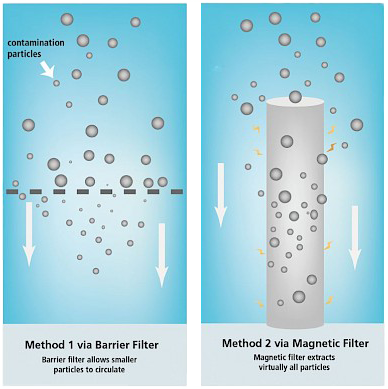

Barrier Filtration vs. Magnetic Filtration

A barrier filter allows particles smaller than the pore size to remain in the fluid, reducing fluid efficiency and increasing wear on machinery and cutting tools. Additionally, barrier filters can become clogged, causing blinding, backpressure, or bursting.

With magnetic filters, high-intensity magnets remove virtually all particles, and clean fluid continues uninterrupted. Once full, the contamination is removed from the filter and can be recycled with minimal fluid loss.

How to Clean a Magnetic Boiler Filter

Regular servicing is necessary to ensure a magnetic boiler filter is working correctly. Cleaning a magnetic boiler filter is recommended once a year, usually during the annual boiler inspection, to remove the debris it has caught and to keep it in good working order.

Instructions for Cleaning a Webstone Magnetic Boiler Filter

Accumulated debris should be removed periodically depending on system conditions. System fluid under pressure can be very hazardous. Before servicing, shut down the heating system and isolate the magnetic boiler filter from the system. Allow the system to cool to below 120°F before proceeding. Keep body away from unit while open. Failure to follow these instructions may cause serious bodily injury or property damage.

- Shut down the heating system. Close the isolation valves on either side of the unit if installed.

- Remove the magnet bar from the MBF body, releasing captured ferrous debris.

- Remove the drain-valve cap, and attach the hose leading to the bucket.

- Use the service tool provided to slowly open the drain valve counterclockwise and allow fluid to drain fully from the unit. The end of the drain cap may also be used to actuate the drain valve. Caution! Fluid will be under pressure.

- Use the service tool to unscrew the MBF lower body. Take care not to damage the o-rings. IMPORTANT: Diverter (if applicable) and upper body must be held in place during disassembly to prevent damaging the unit or system piping.

- Remove the plastic/metal filter and clear trapped debris. Rinse the filter and lower body with clean water.

- Install the filter into the lower MBF body and carefully reassemble it to the upper MBF body, ensuring that no damage is caused to the o-rings. Caution! Maintain o-ring locations during servicing as the two body o-rings are different diameters. Secure body halves to 10 ft-lbs (3/4" & 1" models) or 12 ft-lbs (1-1/4" & 1-1/2" models) of torque. DO NOT OVER-TIGHTEN!

- Reinstall the magnet bar.

- Use the service tool to return the drain valve to the closed position. Replace cap.

- To bleed the unit after servicing, loosen the air vent screw with a screwdriver. Use the service tool to prevent the air vent from rotating. If installed, open the inlet-side isolation valve and allow fluid to fill the unit. Once fluid comes out of the vent, tighten the vent screw and open the outlet-side isolation valve.

- Leak check the unit after servicing—return system to operating condition.

Webstone Magnetic Boiler Filters

Webstone magnetic boiler filters utilize a high-powered 12,000 Gauss magnet. Accumulation can be removed with the strapped cap that actuates the drain valve. A universal diverter allows the magnetic boiler filter to be installed in horizontal and vertical piping orientations. A service tool is included to help install and easily maintain the filter. Webstone magnetic boiler filters are designed for use with water, oil, or glycol mix in residential or commercial heating systems.

Webstone Magnetic Boiler Filter Features

Universal Diverter – allows use with both horizontal and vertical piping orientations.

Flexible Installation – install on either boiler inlet or system return for maximum protection.

Efficiency – high-powered 12,000 Gauss magnet captures ferrous debris and filters iron sludge before it can damage the boiler or pump.

Webstone Magnetic Boiler Filter – The Powerful Way to Stay Efficient

Webstone Magnetic Boiler Filter Models

Figure No. H-7x70

This magnetic boiler filter features a 12,000 Gauss magnet, diverter, integrated hose drain valve, air vent, and filter. It also includes two union end connections and a service tool. The protective sleeve prevents sludge from accumulating directly on the magnet. Remove the magnet, and the debris falls into the cavity below.

Figure No. H-7x71

This magnetic boiler filter features a 12,000 Gauss magnet, diverter, integrated hose drain valve, air vent, and filter. It also includes two union end connections, two isolation valves, and a service tool.

Figure No. H-7x70XL

This magnetic boiler filter features a 12,000 Gauss magnet, diverter, integrated hose drain valve, air vent, and filter. It also includes two union end connections and a service tool. The large filter body increases the time between services. Available in 1-1/4" and 1-1/2" sizes. For use with water or Glycol mixture.