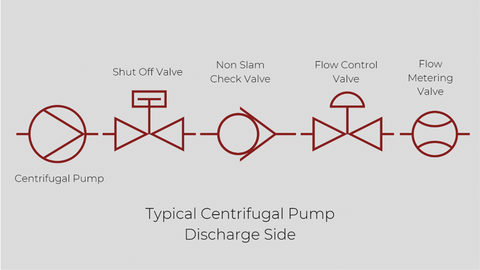

Centrifugal pumps, on most occasions, need to be paired up with various piping accessories to ensure the intended system design, intended operation, and overall longer system lifespan. Those accessories often include:

- Shut-Off Valve – Allows for complete stopping or continuing of fluids in a pipeline. Completely shutting off the pipeline means it is also essential in maintaining and replacing pumps and other equipment in the system.

- Check Valve – Prevents the backward flow of liquid. Especially needed during starts and stops to prevent water hammering that could lead to physical damage to the pump or the entire system.

- Flow Control Valve – Maintains the designed portion of flow in a pipeline.

- Flow Metering Valve – Contains ports that can be plugged with the right measuring tools for differential pressure readings.

Fig 1. Typical centrifugal pump discharge side accessories.

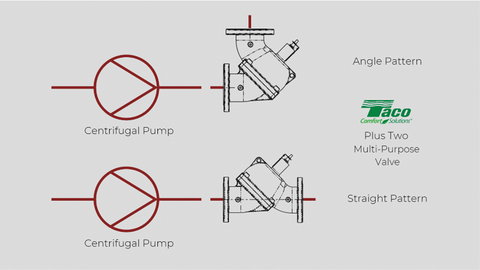

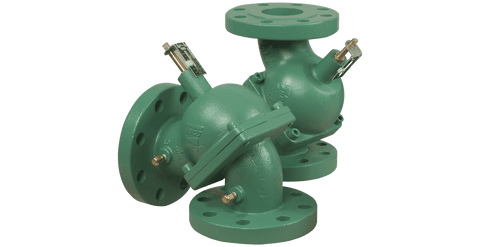

Taco Plus Two Multi-Purpose Valves combine all these valve functions typically required on a centrifugal pump’s discharge side in a hydronic heating or cooling system into one body. These types of valves are sometimes called triple duty valves, but Taco calls them multi-purpose valves or MPVs.

Fig 2. The Taco Plus Two Multi-Purpose Valve on the discharge side can replace up top four valves.

They are field convertible from a straight pattern to a 90º right angle pattern. Each valve has a calibrated nameplate for system balancing (approximate). In addition, all valves are equipped with metering ports for taking differential pressure readings that can be used with corresponding flow charts for more accurate system balance. Plus Two MPVs have low-pressure drops equal to or better than any comparable valve on the market today, and the stem seal packing can be replaced under full system pressure.

Learn more about the different types of triple duty valves in our What is a Triple Duty Valve? blog post.

Taco Plus Two Multi-Purpose Valve Materials

Taco Plus Two Multi-Purpose Valve Body uses heavy-duty materials throughout. Some of the materials used are:

Body – Ductile Iron

In a system that experiences a considerable amount of internal pressure (not to mention heavy pressure fluctuations when things get out of hand), ductile iron is a safer choice than the typical body material cast iron due to its malleability. Cast iron will break and shatter with little to no warning, while ductile iron will deform and give signals before completely tearing.

Seat Disc – Stainless Steel (304)

While typical valves use brass, the Taco Plus Two MPV comes standard with a stainless steel seat disc due to its durability and corrosion-resistant characteristics. This is especially helpful for those extended periods in between maintenance.

Soft Seat – EPDM

An industry standard in hydronics, EPDM is resistant to many chemicals, such as alkalis, mild acidic and oxygenated solvents, steam, and water. As a result, it is perfect for varying fluid temperatures in a heating or cooling piping system.

Other industry-standard materials used for the Taco Plus Two Multi-Purpose Valve are listed below:

- Spring: Stainless Steel (302)

- Gland: Bronze

- Stem Packing: Asbestos-Free Teflon Impregnated Aramid Fiber

- Body O-Ring: EPDM

- Stem: Bronze/Stainless Steel (416)

- Grooved Adapter: Steel

Taco Plus Two Multi-Purpose Valve Capacities & Performance Data

Taco Plus Two Multi-Purpose Valves range in size from 1-1/2" through 14". Each valve is available in 150 psi or 250 psi working pressure with flanged end connections (1-1/2", 2", and 2-1/2" units are threaded connections). In addition, grooved adapters are available.

- Range Flow: 20-10,000 GPM

- Working Pressure: 175 psi & 300 psi

- Connection Sizes: 1-1/2", 2", and 2-1/2" (threaded), 3"-14" (flanged)

Taco Plus Two MPV Applications & Advantages

Taco Plus Two Multi-Purpose Valves are designed for installation in pump discharge piping, where it performs triple duty. They should be used with the Taco RSP-2 Specialty Suction Diffuser and are a compact and effective complete pump protection and isolation package.

Applications of Taco Plus Two Multi-Purpose Valves

Heating & Cooling Systems

- Hot Water Heating Systems – Can be used on centrifugal water circulators.

- Air Conditioning Systems –

- Can be used on chilled water pumps for fluids or cooling medium going into the system.

- Can be used on condenser water pumps for condenser water going into the closed-loop cooling towers.

Industrial Processes

- Closed Cooling Circuits – Can be used on various centrifugal circulators that use water/glycol concentrations up to 50% in industries such as ice factories, cold rooms, etc.

- Solar/Geothermal – Can be used on various centrifugal circulators such as roof heaters, boilers, etc.

Advantages of Taco Plus Two Multi-Purpose Valves

Taco Plus Two Multi-Purpose Valves can be used on these systems to replace typical necessary accessories (shut-off valve, check valve, flow control valve, metering valve). In addition, having only one valve to do the task of four can pose advantages to the system, such as:

- Save Space – Fewer accessories mean lesser space taken up. Perfect for those tight take-off spaces from the pump to the riser.

- Reduce Pressure-Drop – With a comparable or even better pressure drop than most valves of the same function today. Replacing multiple valves with Taco Plus Two MPVs can significantly improve the system performance, and along with it comes a more efficient system that utilizes lower electrical consumption.

See Taco’s line of Specialty Suction Diffusers here: Taco Pump Suction Diffusers.

Choosing the Right Taco Plus Two Multi-Purpose Valves for Centrifugal Pumps

Selecting the right Taco Plus Two Multi-Purpose Valves for your application is a straightforward task. Below are the steps you can use as a guide:

- Select a pressure rating suitable for your system.

- Select a connection size. Since this also works as a flow control valve, you can select a size similar to your system piping.

- Select the proper connection (threaded, flanged, flanged groove, or threaded groove).

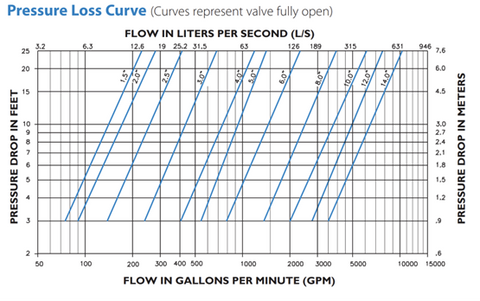

- Take note of the pressure drop depending on the flow rate of your system.

Below are the Taco Plus Two Multi-Purpose Valve Models to choose from:

|

Model Number |

Size |

Connection |

Class 125 |

Class 250 |

|

MPV 015-4 |

1-1/2" (38.1mm) |

Threaded |

✓ |

|

|

MPV 020-4 |

2" (50.8mm) |

Threaded |

✓ |

|

|

MPV 025-4 |

2-1/2" (63.5mm) |

Threaded |

✓ |

|

|

MPV 030-4* |

3" (76.2mm) |

Flanged |

✓ |

✓ |

|

MPV 040-4* |

4" (101.6mm) |

Flanged |

✓ |

✓ |

|

MPV 050-4* |

5" (127.0mm) |

Flanged |

✓ |

✓ |

|

MPV 060-4* |

6" (152.4mm) |

Flanged |

✓ |

✓ |

|

MPV 080-4* |

8" (203.2mm) |

Flanged |

✓ |

✓ |

|

MPV 100-4* |

10" (254.0mm) |

Flanged |

✓ |

✓ |

|

MPV 120-4* |

12" (304.8mm) |

Flanged |

✓ |

✓ |

|

MPV 140-4* |

14" (355.6mm) |

Flanged |

✓ |

✓ |

* Append ‘A’ for Class 250* working pressure angled units (e.g. Model Number MPV 030-4A).

If you need a grooved adaptor for both the flanged or threaded valve, you can select the following adapters below:

|

Model Number |

Size |

Connection |

Class 125 |

Class 250 |

|

TTG015-5 |

1-1/2" |

Threaded - Grooved |

✓ |

|

|

TTG020-5 |

2" |

Threaded - Grooved |

✓ |

|

|

TTG025-5 |

2-1/2" |

Threaded - Grooved |

✓ |

|

|

FTG020-5* |

2" |

Flanged - Grooved |

✓ |

✓ |

|

FTG025-5* |

2-1/2" |

Flanged - Grooved |

✓ |

✓ |

|

FTG030-5* |

3" |

Flanged - Grooved |

✓ |

✓ |

|

FTG040-5* |

4" |

Flanged - Grooved |

✓ |

✓ |

|

FTG050-5* |

5" |

Flanged - Grooved |

✓ |

✓ |

|

FTG060-5* |

6" |

Flanged - Grooved |

✓ |

✓ |

|

FTG080-5* |

8" |

Flanged - Grooved |

✓ |

✓ |

|

FTG100-5* |

10" |

Flanged - Grooved |

✓ |

✓ |

|

FTG120-5* |

12" |

Flanged - Grooved |

✓ |

✓ |

|

FTG140-5* |

14" |

Flanged - Grooved |

✓ |

✓ |

* Append ‘A’ for Class 250* working pressure angled units (e.g. Model Number FTG030-5A).

To make sure your system is meeting the allowable pressure drop when using the Taco Plus Two Multi-Purpose Valve, you can reference the Pressure Loss Curve below:

For individual product performance curves, you can click here to view the Taco Plus Two Multi-Purpose Valve on Taco’s Website: Plus Two Multi-Purpose Valve.

Taco Plus Two Multi-Purpose Valve Operation & Installation Instructions

Taco Plus Two Multi-Purpose Valve Operation

- The disc is spring-loaded to close the valve before flow reversal, protecting the pump and guarding against water hammer.

- The disc opens at .25 psi.

- The disc opens 1/3" for each inch of line size, allowing greater flow.

- The disc is fully guided with an external threaded stem.

- The threaded stem allows flow adjustment from bubble-tight shut-off to full flow.

- A position indicator ensures accurate and repeatable balancing through disc positioning in throttling service.

- The stem and yoke are external unwetted parts not subject to corrosion or erosion by line fluids.

- Field servicing is easy and requires no special tools.

- NPT drain plug is standard.

- Gauge taps are available at both inlet and outlet ends.

Taco Plus Two Multi-Purpose Valve Installation

- It is critical that the Taco Plus Two Multi-Purpose Valve is always installed with the shaft facing upwards, as indicated in the diagrams.

- The Taco Plus Two Multi-Purpose Valve should be mounted to a spool piece on the discharge side of the pump. It is recommended that a spool piece of 12" be used on pumps with a discharge size of 1-1/2" through 6" and a 24" spool piece be used for discharge sizes 8" through 12".

- Mounting the valve directly to the pump is not recommended to prevent any objectionable system noise.

- Provide sufficient clearance around the valve to facilitate removal or repair.

- Valve should be installed in the direction of the flow arrows on the valve body.

- The valve body is not designed to support the weight of the system piping. Pipe hangers must be used and installed correctly in accordance with accepted industry standards/practices. Pipe supports should be provided under the valve bodies.

Taco Plus Two Multi-Purpose Valve Field Conversion (Straight-to-Angle Pattern)

- Open the valve a minimum of one complete turn.

- Remove the body bolts. 1-1/2" through 2-1/2" valves require a 5/16" Allen key. 3" valves require a 3/8" Allen key. 4" valves require a 1/2" Allen key. 5" and 6" valves require a 5/8" Allen key. 8" through 12" valves are 3/4" hex cap bolts.

- Rotate one half of the valve body 180º while ensuring that the body o-ring and the “soft seat” remain in position (inspect the body o-ring and the “soft seat” for any nicks or cuts and replace them as necessary).

- Reinstall the body bolts and torque to 50 ft-lbs.

Replacing the Stem Packing on a Taco Plus Two Multi-Purpose Valve

If a leak develops at the stem packing nut, turn the nut clockwise until the leak stops. If the leak persists, you will need to replace the stem packing; this may be accomplished while the valve is under full system pressure.

- Record valve setting utilizing memory clip.

- Remove retaining rings and calibration nameplate.

- Turn the valve stem counterclockwise until the valve is fully open and will not turn any further.

- Remove the packing nut, located at the base of the stem, by turning counterclockwise.

- Remove old packing and replace it with two new packing rings with the ring joints positioned 180º apart.

- Replace the packing nut and tighten it as required.

- Reinstall calibration nameplate and retaining rings.

- Reposition the valve stem per the recorded setting in step one.

Taco Plus Two Multi-Purpose Valve Flow Meter Operation

- Remove caps from the valves at the HI and LO pressure taps.

- Connect the high-pressure hose (red) of the differential pressure gauge to the upstream of the HI pressure connection on the MPV and the low-pressure hose (green) to the downstream of the LO pressure connection. Note: Hose ends to be connected require valve depressors. Check the opposite end of the hose if not visible inside the hose end. Valves are opened automatically as the hose end is screwed on.

- Prepare the differential pressure gauge as per instructions in the Gauge Kit.

- The flow can be determined by reading the differential pressure indicated at the gauge, noting the valve opening from the scale and pointer, and transferring this data to the Flow Chart (published separately).

- When flow readings are complete, follow the directions supplied with the differential pressure gauge.

- Replace metal caps on valves at the HI and LO pressure taps.

NOTE: In order to achieve optimal accuracy when using any differential pressure flow measuring device, it is recommended that a minimum of 10 diameters of straight pipe (sized to the device) be installed upstream of the device and a minimum of 5 diameters of straight pipe be installed downstream of the device.

Taco Plus Two Multi-Purpose Valves Documentation

Taco Plus Two Multi-Purpose Valve Catalog

Taco Plus Two Multi-Purpose Valve Submittal Data Information

Taco Plus Two Multi-Purpose Valve Instructions

Taco Plus Two Multi-Purpose Valve Replacement Parts List

Conclusion

While various accessories in the market can help a centrifugal pump in its day-to-day operation, the Taco Plus Two Multi-Purpose Valve takes the cake as a multiple-valve-in-one, providing versatility and protection, convenience, design accuracy, and space savings only a few other valves can match.

Are you considering integrating the Taco Plus Two Multi-Purpose Valve in your hydronic piping system? Let us know so we can recommend a model number for you! Shop our collection of Taco Plus Two Multi-Purpose Valves online or email us at support@libertysupply.com today.