An aquastat is a device used in hydronic heating systems, such as those found in many homes and commercial buildings, that control or monitor water temperature. It's essentially a thermostat for hot water.

In a heating system, the aquastat helps manage the operation of the boiler to maintain the water at the desired temperature. For example, when the water in the boiler drops below a certain temperature, the aquastat triggers the boiler to heat the water. The aquastat will shut the boiler off once the water reaches a specific upper limit.

Types of Aquastats

Aquastats come in several types, each designed to control boiler operation slightly differently. The main types are:

Single Function Aquastats

These aquastats have only one function: shut off the boiler when it reaches a specific high temperature. This is known as a high-limit control. These devices are a safety measure to prevent the boiler from overheating.

Dual Function Aquastats

These aquastats serve two functions. They have a high limit control to shut off the boiler at a certain temperature but also a low limit control. The low limit control turns the boiler on when the water temperature falls below a certain point. This aquastat type is often used in systems that provide space heating and domestic hot water.

Triple Function Aquastats

These aquastats have three functions. In addition to the high limit and low limit controls, they also have a circulator control. The circulator control turns on a circulator pump when the water temperature reaches a certain level, moving hot water from the boiler to the heating system.

Strap-On Aquastats

These are a type of surface-mounted aquastat that are physically strapped onto a pipe. They measure the water temperature in the pipe through the pipe wall. These are typically used in applications where an immersion probe is not practical.

Outdoor Reset Aquastats

These advanced controls adjust the temperature of the water in the boiler based on the outdoor temperature. When it's colder outside, the water is heated to a higher temperature; when it's warmer out, it is heated to a lower temperature. This can make the heating system more efficient by aligning the heat output with the heating demand.

Each aquastat type has its own specific applications, advantages, and disadvantages, and the choice of which to use depends on the specifics of the heating system and the needs of the building occupants. Therefore, always consult a heating professional when choosing an aquastat for your system.

How Does an Aquastat Work?

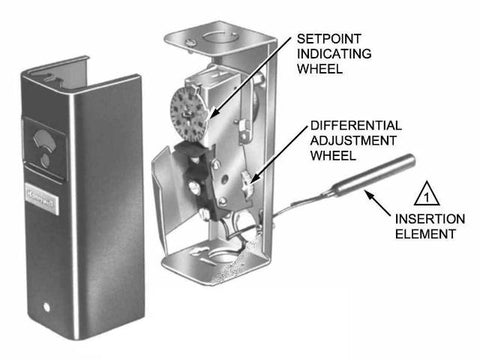

An aquastat uses a temperature-sensing bulb to detect the water temperature within a boiler system. This bulb is usually filled with a substance that expands or contracts based on the water temperature.

The sensing bulb of the aquastat is inserted into the boiler or strapped to a supply pipe. When the boiler water temperature drops below the setpoint on the aquastat, the substance within the sensing bulb contracts, this change triggers a switch inside the aquastat. This switch then signals the boiler to turn on and heat the water.

Conversely, when the temperature of the water reaches the upper limit set on the aquastat, the substance inside the sensing bulb expands. This change triggers the switch to turn the boiler off, stopping it from further heating the water. In systems with a circulator pump, the aquastat can also control when this pump activates or deactivates, ensuring the heated water is circulated in the heating system when it reaches a certain temperature.

Cycling the boiler maintains a consistent and safe water temperature, ensuring efficient heating operation. The specific temperatures at which the boiler is turned on or off can usually be adjusted on the aquastat to fit the needs of the particular heating system.

Aquastat Installation

Generally, installing an aquastat includes the following steps:

- Turn off the power: Before beginning, turn off the power to the boiler to prevent electrical shock.

- Locate the mounting position: The aquastat is usually mounted directly onto the boiler or supply pipe.

- Mount the aquastat: Secure the aquastat according to the manufacturer's instructions, usually by attaching the aquastat to the boiler or pipe with brackets or clamps.

- Insert the sensing bulb: The sensing bulb connected to the aquastat must be inserted into a well in the boiler or attached to the supply pipe to sense the water temperature accurately.

- Connect the wiring: Aquastats have electrical terminals that must be connected to the boiler's control circuitry. Follow the manufacturer's wiring diagram to ensure proper installation.

- Set the temperature: Set the high and low-temperature limits on the aquastat according to the boiler manufacturer's specifications.

- Test the system: After the installation, restore power to the boiler and test the system. Make sure the boiler turns on and off at the appropriate temperature settings.

Advantages & Disadvantages of Aquastats

Aquastats, like any control device, have their own advantages and disadvantages, depending on the specific use case and the type of heating system in question.

Advantages

- Temperature Control – Aquastats allow for precise water temperature control in a boiler system, ensuring consistent heat output.

- Energy Efficiency – By preventing the boiler from unnecessarily heating water above a certain point, aquastats can help save energy and reduce heating costs.

- Safety – Aquastats also serve a safety function by preventing the boiler from overheating, which could cause damage to the system or potentially pose a fire risk.

- Versatility – Different types of aquastats (high-limit, low-limit, and circulator) provide flexible control options depending on the heating system's needs.

Disadvantages

- Complexity – The installation and calibration of an aquastat can be complex and usually requires a qualified professional. Improper installation can lead to inefficient operation or safety issues.

- Maintenance – Like any mechanical device, aquastats can wear out or malfunction over time, requiring replacement or repair.

- Cost – While aquastats can lead to energy savings over time, the upfront cost for the device and its installation can be a disadvantage, especially if replacing a functioning, albeit less efficient, control device.

- Potential Inefficiency – If the aquastat is not properly set up or the system is not designed efficiently, the boiler may cycle on and off more frequently than necessary, leading to wasted energy.

Aquastat FAQs

What is the difference between an aquastat controller and an aquastat relay?

An aquastat controller and an aquastat relay are components often found in the same unit, and the terms are sometimes used interchangeably. However, they perform different functions within the system.

An aquastat controller is responsible for sensing the temperature of the water in the boiler and sending a signal based on that temperature. It has a temperature-sensitive bulb or probe that expands or contracts based on the water's temperature. When the temperature drops below a set point, it signals that the water is too cool. Conversely, when the water temperature rises above a certain point, it signals that it is too hot.

An aquastat relay receives and acts on the signal from the aquastat controller. If the signal indicates the water is too cool, the relay closes the circuit to the burner, causing it to turn on and heat the water. If the signal indicates the water is too hot, the relay opens the circuit to the burner, causing it to shut off.

In many cases, "aquastat controller" and "aquastat relay" refer to the same device because these components are often housed in a single unit. But the controller is the part that senses the temperature, and the relay is the part that acts on that information to control the burner.

What is the difference between a high-limit aquastat and a low-limit aquastat?

High-limit and low-limit aquastats serve different functions within a boiler system.

High-limit aquastats are designed to prevent boilers from overheating. They monitor the temperature of the water in the boiler and shut it off when that temperature reaches a set limit (typically around 180°F or 82°C, though the exact limit can vary). Once the water temperature drops below a certain point (the limit minus the differential), a high-limit aquastat allows the boiler to turn back on.

Low-limit aquastats are designed to keep boilers running until the water reaches a specific minimum temperature. When the water temperature falls below this limit (often set around 160°F or 71°C, though it can vary), low-limit aquastats signal the boiler to turn on and start heating the water. Once the water reaches the set limit, the boiler turns off. This is often used in systems with a hot water storage tank to maintain a minimum temperature in the tank.

Some boilers use a dual aquastat that combines high- and low-limit functions into a single unit. This aquastat type can turn the boiler on when the water temperature falls too low and off when it rises too high, ensuring that the boiler operates within a set temperature range. The differential setting determines how much the water temperature must drop below the high limit before the boiler turns on again.

What is an aquastat well?

An aquastat well, also known as a thermowell or immersion well, is a boiler system component that houses the aquastat's sensing bulb. It is a protective sleeve inserted directly into the boiler or a pipe in the system.

The well allows the temperature-sensing bulb of the aquastat to accurately measure the temperature of the water in the boiler without being exposed to the pressure of the water itself. This helps protect the bulb and extends the life of the aquastat. The aquastat's sensing bulb is inserted into the well, and heat from the water is transferred through the walls of the well to the bulb.

What is a circulator aquastat?

A circulator aquastat is a type of aquastat that controls the operation of the circulator pump in a boiler system. The circulator aquastat monitors the temperature of the water in the boiler. When the water reaches a specific temperature, the circulator aquastat signals the circulator pump to turn on and start moving the hot water into the heating system. The circulator aquastat signals the pump to turn off when the water temperature falls below a set limit.

By controlling the operation of the circulator pump based on the water temperature, the circulator aquastat helps ensure that the water is at the right temperature for effective heating when it's sent into the heating system. It also helps to manage the heating system's efficiency by avoiding unnecessary pump operation.

Can a hydronic heating system function without an aquastat?

While a hydronic heating system could technically function without an aquastat, it wouldn't be safe or efficient. An aquastat turns the boiler on when the water temperature falls below a certain level and off when the temperature rises above a set limit. With this regulation, the boiler would know when to turn on and off.

If a boiler were to operate without an aquastat, the boiler could continue heating the water even after it reaches the desired temperature and overheat, potentially causing damage to the system or even a fire risk. The boiler might also keep heating the water above the necessary temperature, wasting energy and increasing utility bills.

Conversely, without an aquastat, the boiler might not turn on when needed, leading to insufficient heating. Without proper temperature control, the boiler might cycle on and off more frequently than necessary, causing wear and tear on the system.

So, while it's technically possible for a hydronic heating system to operate without an aquastat, it would be neither safe nor efficient. An aquastat is a vital component for managing the operation of the boiler and ensuring the efficient use of energy.

Are aquastats normally open or normally closed?

Aquastats can be either normally open or normally closed, depending on the specific model and its role in the heating system.

Whether an aquastat is normally open or normally closed depends on whether it's meant to turn the boiler on when the water is too cold (in which case it would be normally open) or turn the boiler off when the water is too hot (in which case it would be normally closed). Therefore, it's crucial to ensure that the correct aquastat type is used for the intended function in the heating system.

What temperature should an aquastat be set at?

The correct setting for an aquastat depends on the specific heating system and the comfort needs of the occupants, but there are general guidelines.

For a single-function, high-limit aquastat, designed to shut off the boiler if the water temperature becomes too high, a typical setting is around 180°F (82°C). This prevents the water in the boiler from reaching boiling point and creates a potential safety hazard.

There are two settings for a dual-function aquastat, which both turns on the boiler when the water is too cold and turns it off when it is too hot. The high limit is typically set to around 180°F (82°C), and the low limit, which triggers the boiler to turn on, might be set to around 160°F (71°C).

A differential setting also determines how much the water temperature has to drop below the high limit before the boiler turns on again. A common differential setting is around 10 to 20 degrees. For systems with a circulator control, the settings can vary more widely.

How do I adjust the settings on my aquastat?

The process of adjusting the settings on an aquastat can vary based on the specific model and type of the device, but here is a general step-by-step guide:

- Turn off the power – Before making any adjustments, turn off the power to the boiler to avoid potential electrical hazards.

- Locate the aquastat – The aquastat is usually located on or near the boiler, often in a protective box or casing.

- Access the controls – Open the protective cover on the aquastat to reveal the control dials or switches.

- Identify the settings – There should be two temperature settings on a dual-function aquastat: a "high" or "HI" setting that specifies the maximum temperature and a "low" or "LO" setting that specifies the minimum temperature. A "differential" or "DIFF" setting may also specify how much the temperature should drop below the high setting before the boiler turns back on.

- Adjust the settings – Use a screwdriver or other tool (as specified by the manufacturer) to adjust the settings. Turn the dial or move the switch to the desired temperature. A common high limit setting is around 180°F (82°C), and a common low limit setting is around 160°F (71°C). The differential is often set around 10 to 20 degrees.

- Check the settings – After making the adjustments, double-check the settings to ensure they are at the desired levels.

- Close the aquastat – Replace the cover on the aquastat.

- Turn the power back on – Once you've finished making adjustments, turn the power back on to the boiler.

- Monitor the system – Over the next few hours and days, keep an eye on the system to ensure it's operating correctly at the new settings.