LWCOs, or Low Water Cutoff devices, play a crucial role in ensuring the safe and efficient operation of boiler systems. Among the leading manufacturers of LWCOs, McDonnell & Miller stands out with their innovative and reliable products.

What is a Low Water Cutoff?

Low Water Cutoff devices are safety devices installed in boiler systems to monitor the water level and prevent the boiler from operating in low water conditions. They act as a fail-safe mechanism to shut down the boiler when the water level drops below a specified threshold. This helps avoid dry firing, a situation where the boiler operates without sufficient water, leading to overheating and potential damage.

Discover "What is a Low Water Cutoff?" in More Detail

Why are they important in boiler systems?

LWCOs are critical components in boiler systems for several reasons. Firstly, they protect the boiler from operating in low water conditions, which can cause damage to the heating elements, tubes, and other components. Secondly, LWCOs enhance boiler efficiency by ensuring adequate water levels, promoting optimal heat transfer and preventing energy waste. Lastly, these devices contribute to overall safety by minimizing the risk of accidents, such as explosions, that can occur due to low water conditions.

The History of McDonnell & Miller

Boilers are widely used in various industries and residential buildings for heating and hot water generation. However, boiler systems can be susceptible to low water conditions, leading to boiler damage, reduced efficiency, and even safety hazards. McDonnell & Miller, a renowned manufacturer in the industry, offers a range of LWCOs designed to prevent such issues and ensure optimal boiler performance. They are also known for their boiler controls, flow switches, and liquid level controls.

The company was founded in 1924 by Col. W. B. McDonnell and Mr. George D. Miller in Chicago, Illinois. They first came into the limelight with their invention of the low water cutoff (LWCO) device, which became a vital safety device for steam boilers. The innovation was prompted by the increasing number of boiler explosions and the need to make heating systems safer.

McDonnell & Miller expanded their product line over the decades, adding water feeders, flow switches, and other controls, becoming an industry leader in boiler and level control products.

In the 1990s, McDonnell & Miller was acquired by ITT Industries. ITT Industries later spun off several of its business segments, including its water technology businesses, which were incorporated as Xylem Inc. in 2011.

Read more about McDonnell & Miller

How do McDonnell & Miller LWCOs work?

McDonnell & Miller LWCOs utilize advanced technologies to monitor the water level in boiler systems accurately. These devices are typically equipped with probes or sensors that detect the presence or absence of water. When the water level drops below the predetermined level, the LWCO signals the boiler controls to shut down the system, preventing further operation until the water level is restored. This ensures the boiler's longevity while minimizing the risk of damage and accidents.

Types of Low Water Cutoffs

Low Water Cutoffs (LWCOs) can be broadly categorized into two types based on their operating principle: float-type and probe-type. Each style comes in various models and can be tailored to specific needs.

Each type of LWCO has its advantages and disadvantages, and the choice between them depends on the specific needs of the boiler system. Float-type devices are generally more straightforward and reliable, but they may respond slowly to changes in water level. Probe-type devices can react more quickly, but they can be affected by scale buildup on the probe, which might impede their operation over time.

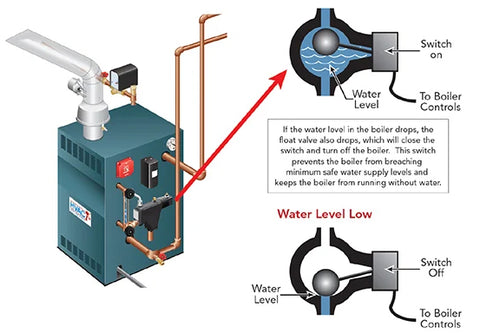

Mechanical Float-Type Low Water Cutoffs

These devices use a float mechanism similar to one in a toilet tank. The float is inside a chamber connected to the boiler. When the boiler's water level drops, the float chamber's water level also drops, causing the float to descend. When the float descends to a certain level, it triggers a switch that shuts off the burner.

Float-type LWCOs are further divided into external and internal models. External models are installed outside the boiler and have a sight glass that allows you to check the water level visually. Internal models are installed inside the boiler and do not visually indicate the water level.

Probe-Type Low Water Cutoffs

These devices use a probe or sensor to detect the presence of water. The probe is usually a rod that extends into the boiler. It works based on the electrical conductivity of water. When the probe is surrounded by water, a circuit is completed. When the water level drops below the probe, the circuit is broken, and the burner is shut off.

Probe-type LWCOs can be further divided into models that use one probe or two probes. In a two-probe system, one probe detects the water level, and the other acts as a ground reference.

Major Differences Between LWCO Types

Different low water cutoffs are designed based on various mechanisms and principles to perform the same fundamental task – to shut down the boiler when water levels fall below a safe threshold. Significant differences between the types of LWCOs include:

Operating Principle

- Float-type LWCO operate on the principle of buoyancy. A float in a chamber connected to the boiler rises and falls with the water level. When the water level falls too low, the float triggers a mechanism to shut down the boiler.

- Probe-type LWCOs, also known as conductivity-type LWCOs, operate on the principle of electrical conductivity. Probes inserted into the boiler form part of an electrical circuit completed when surrounded by water (since water is a conductor of electricity). The circuit is broken when the water level falls below the probe, triggering the boiler to shut down.

Responsiveness & Sensitivity

- Float-type LWCOs are generally less sensitive than probe types and might respond slower to rapid changes in water level.

- Probe-type LWCOs respond more quickly to changes in water level due to their sensitivity. However, they can be affected by scale buildup on the probe, potentially causing them to fail.

Visual Indication

- Some float-type LWCOs, particularly external models, have a sight glass that allows for visual inspection of the water level.

- Probe-type LWCOs do not provide a visual indication of the water level.

Maintenance & Reliability

- Float-type LWCOs are generally more reliable and require less maintenance. However, they can fail due to mechanical float or switch mechanism issues.

- Probe-type LWCOs require regular cleaning to prevent mineral or scale buildup on the probe, which can interfere with their operation.

Key Features of McDonnell & Miller LWCOs

McDonnell & Miller LWCOs are known for their exceptional features, which contribute to their reliability and effectiveness in safeguarding boiler systems.

Advanced Technology & Design

McDonnell & Miller incorporates state-of-the-art technology and engineering in their LWCOs. The devices are designed to provide accurate and consistent water level monitoring, ensuring optimal performance and protection for the boiler.

Reliable Operation & Safety Features

These LWCOs are engineered to provide reliable and fail-safe operation. They are equipped with safety features that enable them to detect water level changes promptly and respond by shutting down the boiler system when necessary. McDonnell & Miller's LWCOs prioritize safety, preventing potential hazards associated with low water conditions.

Easy Installation & Maintenance

McDonnell & Miller LWCOs are designed with ease of installation and maintenance in mind. They are available in various configurations to suit different boiler systems and come with clear instructions and mounting options. Regular maintenance and troubleshooting are also simplified, minimizing downtime and ensuring efficient operation.

Automatic Shut-Off & Alarm Systems

McDonnell & Miller LWCOs ensure the safety and efficiency of boiler operations through automatic shut-off systems. These devices detect low water levels and promptly shut down the boiler to prevent overheating, damage, or explosions. Furthermore, many LWCO models feature alarm systems that provide early warnings before reaching the cutoff point, enabling preventative measures to be taken.

Energy Efficiency & Cost Savings

McDonnell & Miller's LWCOs serve as safety devices for boiler systems, but they offer more than just protection. They prevent costly damage by shutting off the boiler when water levels are insufficient, saving on repair or replacement expenses. They also extend the boiler's lifespan, maximize operational efficiency, and reduce the risk of unplanned downtime in commercial and industrial applications. While LWCOs themselves don't directly enhance energy efficiency, they contribute by maintaining optimal boiler conditions and can be integrated into control systems for potential energy savings.

Benefits of Using McDonnell & Miller LWCOs

Installing McDonnell & Miller LWCOs in your boiler system offers several advantages that contribute to the system's overall performance, longevity, and safety.

Enhanced Boiler Efficiency

By ensuring adequate water levels, McDonnell & Miller LWCOs contribute to enhanced boiler efficiency. When a boiler operates with low water levels, it experiences increased heat transfer resistance, leading to reduced efficiency and higher energy consumption. With an LWCO, the boiler can operate optimally, resulting in energy savings and lower operating costs.

Protection Against Low Water Conditions

The primary function of LWCOs is to protect the boiler from operating in low water conditions. McDonnell & Miller LWCOs detect water level changes effectively and shut down the system when necessary, preventing dry firing and associated risks. This protection helps extend the lifespan of the boiler and reduces the need for costly repairs or replacements.

Prevention of Boiler Damage & Accidents

Operating a boiler in low water conditions can cause severe damage to the equipment. Dry firing can lead to overheating, warping of components, and even catastrophic failures. McDonnell & Miller LWCOs act as a safety net, preventing such damage by shutting down the boiler when the water level is insufficient. By avoiding these risks, you can maintain a reliable and safe boiler system.

Compliance with Industry Regulations

Boiler systems are subject to various industry regulations and codes. McDonnell & Miller LWCOs are designed to meet or exceed these requirements, ensuring compliance and adherence to safety standards. By installing these approved devices, you can have peace of mind knowing that your boiler system is in line with the necessary regulations.

McDonnell & Miller LWCO Applications

McDonnell & Miller LWCOs find applications in various settings, including residential buildings, commercial and industrial facilities, and HVAC systems.

Residential Buildings

In residential settings, boilers are commonly used to heat and provide hot water. McDonnell & Miller LWCOs offer homeowners a reliable solution to protect their boiler systems from low water conditions. Whether it's a single-family home or a multi-unit apartment building, these devices provide peace of mind, ensuring the safe and efficient operation of the boiler.

Commercial & Industrial Facilities

Boiler systems are vital in commercial and industrial facilities, such as hospitals, schools, manufacturing plants, and office buildings. McDonnell & Miller LWCOs are suitable for these applications, where maintaining optimal water levels is essential to meet the demands of the facility. In addition, these devices help prevent disruptions, protect valuable equipment, and promote a safe working environment.

HVAC Systems

LWCOs are also integral to HVAC systems that utilize boilers for heating purposes. McDonnell & Miller LWCOs can be seamlessly integrated into these systems, ensuring reliable operation and preventing any adverse effects of low water conditions on the boiler's performance.

Choosing a McDonnell & Miller LWCO

Choosing the right McDonnell & Miller Low Water Cutoff (LWCO) depends on various factors related to your specific boiler or heating system. Here are some considerations:

- Boiler Type – Is your system a hot water or steam boiler? Some LWCOs are specifically designed for one or the other.

- Boiler Capacity – The size and capacity of your boiler will influence the type of LWCO you need. Larger commercial boilers might need a different LWCO than smaller residential boilers.

- Installation Requirements – Some models are externally mounted, while others are designed for internal installation. The physical constraints of your boiler and installation location could affect your choice.

- Operating Pressure – Different LWCOs are designed to withstand different pressures. Choose a model that is suitable for your system's operating pressure.

- Budget – Consider your budget. While it's crucial not to compromise on safety, prices can vary, and more advanced models might offer features that aren't necessary for your specific needs.

- Maintenance & Service – Think about the ease of maintenance and service availability. Some models might be easier to clean, and service than others, and local availability of qualified service technicians can also be a factor.

- Regulatory Requirements – Ensure the LWCO you choose meets any relevant local and national regulations or standards. This might be particularly relevant in commercial or industrial applications.

Consulting with a heating professional can be highly beneficial. They can consider the specifics of your system and requirements to help you choose the best McDonnell & Miller LWCO for your needs. Always follow professional advice and manufacturer guidelines when installing and maintaining your LWCO to ensure safety and effectiveness.

Installation & Maintenance of McDonnell & Miller LWCOs

Proper Placement & Installation

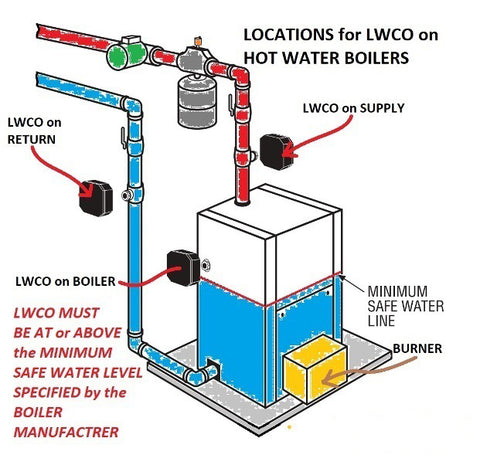

The proper placement and installation of a McDonnell & Miller LWCO depends on the type of boiler and the specific model of the LWCO. However, the following general instructions often apply:

- Placement – LWCOs should be placed at or above the manufacturer's recommended minimum water level for the boiler. For externally mounted devices, this typically means installation in a pipe tee on the boiler side. Internally mounted devices are installed directly into the boiler.

- Orientation – Many float-type LWCOs must be installed horizontally to function correctly.

- Electrical Connections – Electrical connections should be made according to the manufacturer's instructions. The power supply voltage and frequency should match the specifications on the device's nameplate. Electrical connections should also be made in accordance with local and national electrical codes.

- Plumbing Connections – Plumbing connections must also follow the manufacturer's instructions. All connections should be leak-tight to prevent boiler water from escaping.

- Testing – Once installed, the LWCO should be tested to verify proper operation. This typically involves simulating a low water condition and checking that the boiler shuts off.

Specific details, including required tools and materials, will vary between models and boiler types. Always refer to the manufacturer's instructions or consult a professional to ensure a safe and effective installation. Remember that improper installation or misuse of a LWCO can result in device failure, which could lead to boiler damage or even a dangerous condition. Therefore, it's critical to have these devices installed by qualified professionals.

Maintenance Schedule & Procedures

Maintaining a McDonnell & Miller LWCO is crucial to ensure its proper operation and to maintain the safety of the boiler system. Here's a general guide to maintenance procedures for these devices, though specifics may vary between different models:

- Inspection – McDonnell & Miller recommends a visual inspection of the LWCO weekly during the heating season. Check for any obvious signs of wear or damage.

- Testing – A functional test of the LWCO should be performed monthly. This involves simulating a low water condition and checking that the LWCO shuts off the boiler. The test procedure will vary based on the type of LWCO (float-type or probe-type) and whether the device is manual-reset or automatic-reset.

- Cleaning – At least once a year (typically at the beginning of the heating season), the interior of the LWCO should be cleaned. This involves shutting off the boiler, letting it cool, isolating the LWCO, and then opening it up for cleaning. Specific cleaning procedures will vary depending on the type of LWCO and its model.

- Replacement – Worn or damaged parts should be replaced as needed. If the LWCO becomes worn or damaged, it should be replaced entirely.

Remember that these are general guidelines, and the exact maintenance schedule and procedures can vary depending on the specific LWCO model and the boiler system conditions. Always refer to the manufacturer's instructions. Improper maintenance or misuse of an LWCO can lead to device failure, which could result in boiler damage or even a dangerous condition. Therefore, it's critical to follow recommended maintenance procedures and schedules.

Troubleshooting McDonnell & Miller LWCOs

Common LWCO Issues & Their Causes

Low water cutoffs are critical safety devices on a boiler. When they malfunction, it can lead to severe problems. Here are some common LWCO issues and their potential causes:

- Boiler Does Not Shut Off During Low Water Conditions – This can be very dangerous, leading to boiler damage or even a boiler explosion. The cause might be a malfunctioning LWCO, which could be due to a worn or damaged switch, probe, or float mechanism. It could also be due to sediment or scale build-up interfering with the operation of the LWCO.

- Boiler Shuts Off Even Though Water Level Is Adequate – This could be due to a malfunctioning LWCO incorrectly sensing a low water condition. Possible causes include a worn or damaged switch, probe, or float or interference from sediment or scale build-up.

- LWCO Does Not Respond to Manual Test – This could indicate a problem with the LWCO's switch or internal components. If the LWCO does not respond to a manual test, it may not operate correctly during a low water condition.

- Frequent LWCO Alarms or Boiler Shutdowns – If the LWCO frequently triggers alarms or shuts down the boiler, this could indicate a problem with the boiler's water feed system. It could also be due to swings in the boiler water level, which might be caused by issues with the boiler's design or operation.

- Leaking LWCO – Leaks can occur due to worn or damaged seals or connections. Leaks can also be a sign of excessive pressure in the boiler.

- Scale or Sediment Build-Up – Over time, scale or sediment can build up inside the LWCO, potentially interfering with its operation. Regular cleaning and maintenance can help prevent this issue.

Steps for Resolving Common Problems

Troubleshooting and resolving common problems with low water cutoffs requires a systematic approach. Here are some general steps you could take:

-

Boiler Does Not Shut Off During Low Water Conditions:

- Inspect the LWCO mechanism (float or probe) for obstructions or damage.

- Clean the LWCO if sediment or scale build-up is suspected.

- If the device is still not working correctly, consider replacing it.

-

Boiler Shuts Off Even Though Water Level Is Adequate:

- Similar to the previous point, inspect and clean the LWCO.

- Verify the water level in the boiler. An incorrect reading could suggest an issue with the LWCO or the gauge glass.

- Check for boiler system problems that could cause water level fluctuations.

- Consider replacing the LWCO if problems persist.

-

LWCO Does Not Respond to Manual Test:

- Inspect the LWCO for obvious signs of damage or wear.

- Consider replacing the LWCO if it does not respond to a manual test.

-

Frequent LWCO Alarms or Boiler Shutdowns:

- Check the boiler feed system to ensure it is delivering water correctly.

- Look for issues with the boiler system that might cause water level fluctuations.

- Inspect, clean, and, if necessary, replace the LWCO.

-

Leaking LWCO:

- Inspect the LWCO for leaks around seals or connections. If leaks are found, necessary parts should be replaced.

- If the boiler pressure is excessively high, it could cause leaks. In this case, you should inspect the boiler's pressure relief valve and pressure settings.

-

Scale or Sediment Build-up:

- Regular cleaning should be performed to prevent scale or sediment build-up.

- In severe cases, the LWCO might need to be replaced.

Remember, these steps are for guidance only. Always consult with a professional or the manufacturer's instructions when dealing with issues related to your LWCO. Misunderstanding or misapplying troubleshooting procedures can lead to ineffective solutions or, worse, dangerous situations.

McDonnell & Miller LWCO Models

McDonnell & Miller produces several series of Low Water Cutoffs (LWCOs), each with specific models designed to meet a variety of needs in the boiler and heating systems industry.

McDonnell & Miller Series 61 LWCOs

Series 61 LWCOs are ideal for residential and commercial low-pressure steam boiler applications and boilers of any steaming capacity.

Features:

- Adjustable BX outlet for easy installation

- Dual precision switches for dependable operation of the low water cut-off and alarm or electric water feeder

- Packless bellows

- 1" NPT equalizing pipes and blow-down valve required

- Maximum steam pressure: 20 psi (1.4 kg/cm2)

McDonnell & Miller Series 63 LWCOs

Series 63 LWCOs are for residential, commercial, and industrial applications.

Features:

- Heavy duty

- Includes No. 2 switch

- Optional manual reset available

- Maximum boiler pressure: 50 psi (3.5 kg/cm2)

- Use with TC-4 valves on hot water systems

McDonnell & Miller Series 64 LWCOs

Series 64 LWCOs are ideal for residential, commercial, and industrial boiler applications of any steaming capacity.

Features:

- Heavy duty

- Adjustable BX outlet for easy installation

- Dual precision switches for dependable operation of the low water cut-off and alarm or electric water feeder

- Packless bellows

- Optional manual reset available

- 1" (25mm) NPT equalizing pipes required

- Maximum boiler pressure: 50 psi (3.5 kg/cm2)

- Use with TC-4 valves on hot water systems

McDonnell & Miller Series 67 LWCOs

Series 67 LWCOs are for residential and commercial applications and boilers of any steaming capacity.

Features:

- Quick hook-up fittings provided

- Lever-operated, full port ball valve for easy blowdown

- Adjustable BX outlet for easy installation

- Dual precision switches for dependable operation of the low water cut-off and alarm or electric water feeder

Optional Features:

- Low voltage switches for self-generating millivolt circuits

- Manual reset switch

- Large float chamber

- Maximum steam pressure: 20 psi (1.4 kg/cm2)

McDonnell & Miller Series 69 Built-In LWCOs

Series 69 built-in LWCOs are for residential and commercial low-pressure steam boiler applications and boilers of any steaming capacity.

Features:

- For mounting in 2-1/2" NPT boiler side tappings

- Insertion lengths available in 13/16" to 4-1/8" (30-105mm)

- Packless bellows

- Adjustable BX outlet for easy installation

- Dual precision switches for dependable operation of the low water cut-off and an alarm or electric water feeder

- Millivolt circuits

- Maximum steam pressure: 20 psi (1.4 kg/cm2)

McDonnell & Miller Series 764 LWCOs

Series 764 LWCOs are ideal for residential, commercial, and industrial boiler applications of any steaming capacity.

Features:

- Heavy duty

- Adjustable BX outlet for easy installation

- Dual precision switches for dependable operation of the low water cut-off and alarm or electric water feeder

- Packless bellows

- 21⁄2″ NPT side tapping provided for installation with close nipple

- Maximum boiler pressure: 50 psi (3.5 kg/cm2)

McDonnell & Miller Series 767 LWCOs

Series 767 LWCOs are ideal for residential and commercial low-pressure boiler applications and boilers of any steaming capacity.

Features:

- 2-1/2" NPT body tapping for side mounting on boilers

- Lever-operated, full port ball valve for easy blowdown

- Adjustable BX outlet for easy installation

- Dual precision switches for dependable operation of the low water cut-off and alarm or electric water feeder

- Large float chamber

- Maximum steam pressure: 20 psi (1.4 kg/cm2)

McDonnell & Miller Series 1575 LWCOs

The Series 1575 provides continuous protection against a low water condition and satisfies pump control needs for commercial and industrial steam boilers. In addition, Series 1575 LWCOs compensate for rapidly changing water levels. They offer adjustable burner and pump settings, as well as powerful 1 HP relays.

Features:

- Primary low-water fuel cut-off protection and pump control for commercial and industrial steam boilers

- Motorized valve controller, low water cut-off, high water cut-off, and alarm actuator for boilers, vessels, and tanks

Shop McDonnell & Miller Mechanical LWCOs

McDonnell & Miller Combination LWCO & Pump Controls

McDonnell & Miller Series 42S LWCO/Pump Controllers

Series 42S is for residential, commercial, and industrial low and medium-pressure steam boilers with a separate water column and boilers of any steaming capacity.

Features:

- Monel bellows provide corrosion resistance

- Single pole, single throw snap action switches

- Enclosed junction box protects switches

- Maximum pressure: 50 psi (3.5 kg/cm2)

Optional Features:

- Quick hook-up fittings

- Gauge glass connector

McDonnell & Miller Series 93/193, 94/194 LWCO/Pump Controllers

Series 93/193, 94/194 LWCOs are for commercial and industrial low or high-pressure steam boilers.

Features:

- Maintains consistent water level regardless of pressure

- Water column with integral tappings for gauge glass and tri-cock installations

- For boilers of any steaming capacity

- No. 5 switch included

- Magnetic repulsion eliminates the need for bellows

Optional Features:

- Manual reset

- 7B switch (135ohm proportional control signal) to maintain constant boiler water level

- 1" NPT connections

- Maximum pressure: 150 psi (10.5 kg/cm2) – Series 93/193

- Maximum pressure: 250 psi (17.6 kg/cm2) – Series 94/194

McDonnell & Miller Series 150S/157S LWCO/Pump Controllers

Series 150S/157S combination LWCO/pump controllers are ideal for commercial and industrial low or high-pressure boiler applications and boilers of any steaming capacity.

Features:

- Monel bellows provide corrosion resistance

- Snap action switches for high-temperature service

- One single pole, single throw switch for pump control

- One single pole, double throw switch for low water

- Cut-off and alarm actuation

Optional Features:

- Manual reset

- Two single pole, single throw switches

- Two single pole, double throw switches

- Float block

- BSPT threads

- Maximum pressure: 150 psi (10.5 kg/cm2)

- Model 150S-MD features maximum differential operation – prevents nuisance burner shutdowns in low-pressure applications

Shop McDonnell & Miller Combination LWCO & Pump Controls

McDonnell & Miller Series PSE Probe Type LWCOs

Series PSE-800 probe-type LWCO use patented technology to monitor changes in water conductivity. When defined parameters are exceeded, the PSE-800 decides to shut the burner off based on the volatility/variability of the resistance readings. This patented technology provides the best protection without turning off the boiler unless a low water condition exists. As an added safety measure, the control will turn off the boiler if it recognizes an out-of-water condition when the sensitivity threshold is exceeded.

Features:

- Green power is on indicating LED

- Red low water indicating LED

- 30 second DOM

- Test button

- Self-Cleaning probe

- No lockout with loss of power if the probe is in water

- Provisions to add water feeder of alarm

- Models available with:

- 120 VAC

- 24 VAC (meets ANSIZ21.13a specification)

- ‘U’ probe (extended barrel)

- ‘FIX2′ probe (remote)

McDonnell & Miller Series PSE-800-M Probe-Type LWCOs

The Series PSE-800-M Manual Reset LWCO is used as the secondary LWCO on steam boilers and can be used as the primary LWCO on hot water heating boilers. A self-cleaning probe, available only on McDonnell & Miller probe-type controls, reduces probe maintenance to once every five years instead of annually. In addition, manual reset models meet the requirements of ASME Standard CSD-1.

Features:

- Lockout delay

- CSD-1 code compliance

- Power interruption

- Test button

- “Green” power on and “Red” LWCO LEDs

McDonnell & Miller Series 750 and 751P/752P LWCOs

Series 751P/752P probe-type LWCOs protect against low water conditions for commercial and industrial applications. These controls are fully CSD-1 compliant and are primarily used as LWCOs on hot water heating boilers.

Features:

- 120V/24V models available

- Green LED indicates power on

- Red LED indicates low water

- Test button

- Meets requirements of ASME Standards CSD-1

- No lockout with loss of power if the probe is in water

- 20,000 ohms probe sensitivity

McDonnell & Miller RB-24E LWCOs

McDonnell & Miller’s RB-24E patented self-cleaning probe minimizes scale build-up and extends the recommended cleaning interval to five years.

McDonnell & Miller RB-122-E LWCOs

RB-122-E LWCOs are for residential and commercial applications.

Features:

- Electronic operation

- Easy to install and wire

- Red low water indicating LED

- Green power indicating LED

- Test button

- Automatic reset

- No blow down required

- 20,000 ohms probe sensitivity

- Maximum ambient temperature: 120°F (49°C)

- Maximum water temperature: 250°F (121°C)

- Maximum water pressure: 160 psi (11.2 kg/cm2)

Shop McDonnell & Miller Electronic LWCOs

McDonnell & Miller LWCO FAQs

What is the purpose of an LWCO in a boiler system?

An LWCO serves as a safety device in boiler systems. Its primary function is to monitor the water level and shut down the boiler when it drops below a specified threshold. This prevents the boiler from operating in low water conditions, which can cause damage and safety hazards.

Are McDonnell & Miller LWCOs compatible with different boiler types?

Yes, McDonnell & Miller LWCOs are designed to be compatible with a wide range of boiler types, including residential, commercial, and industrial boilers. However, it's essential to select the appropriate model based on the specifications and requirements of your specific boiler system.

How often should I test my McDonnell & Miller LWCO?

Testing your McDonnell & Miller LWCO periodically is recommended to ensure its proper functioning. Regular testing, ideally part of routine maintenance, helps identify potential issues or malfunctions and allows for prompt troubleshooting and repairs.

Can I install the McDonnell & Miller LWCO myself, or should I hire a professional?

While installation procedures may vary depending on your specific boiler system and the model of the LWCO, it's generally advisable to have the device installed by a qualified professional. They have the expertise and knowledge to ensure proper installation and integration with your boiler controls.

Are McDonnell & Miller LWCOs compliant with industry safety regulations?

Yes, McDonnell & Miller LWCOs are designed and manufactured to meet or exceed industry safety regulations and standards. By installing these approved devices, you can ensure compliance with relevant codes and regulations, promoting a safe and reliable boiler system.

Conclusion

McDonnell & Miller LWCOs offer an effective and reliable solution for protecting boiler systems from the dangers of low water conditions. With their advanced technology, reliable operation, and easy installation, these devices contribute to enhanced boiler efficiency, prevention of damage, and compliance with safety regulations. Whether in residential, commercial, or industrial settings, McDonnell & Miller LWCOs provide peace of mind, ensuring the smooth and safe operation of boiler systems.