What Does an Expansion Tank Do?

When water is heated, it expands, increasing the pressure in closed heating systems. Over time, these pressure fluctuations can damage system components such as valves, pipes, and other fixtures. An expansion tank is designed to handle the thermal expansion of water as it heats up in the water heater, preventing excessive water pressure and extending the system’s life.

Bladder Tank vs. Diaphragm Tank

The most significant difference between a bladder and diaphragm pressure tank is that a bladder pressure tank holds water in a balloon-like bladder. In contrast, a diaphragm pressure tank holds water under a diaphragm in the middle of the tank.

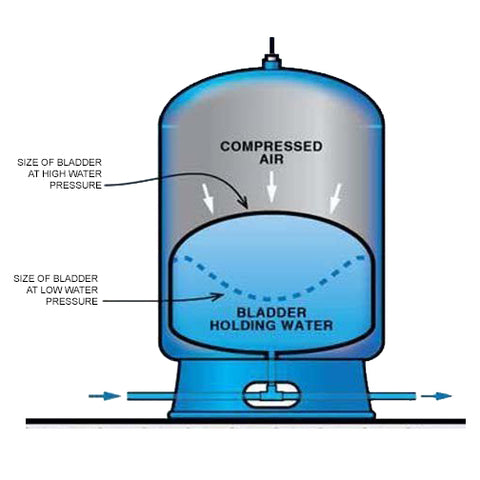

Bladder-Style Expansion Tanks

A bladder expansion tank contains a balloon-like bladder (also called a rubber membrane or diaphragm) inside the shell. This component of the bladder tank can be replaced when required.

Pre-charged bladder expansion tanks from Bell & Gossett are designed to absorb thermal expansion forces in hydronic heating and cooling systems. Their rubber membranes isolate the air from the system fluid, preventing the tank’s waterlogging. At the same time, the pre-charge minimizes the size of the tank.

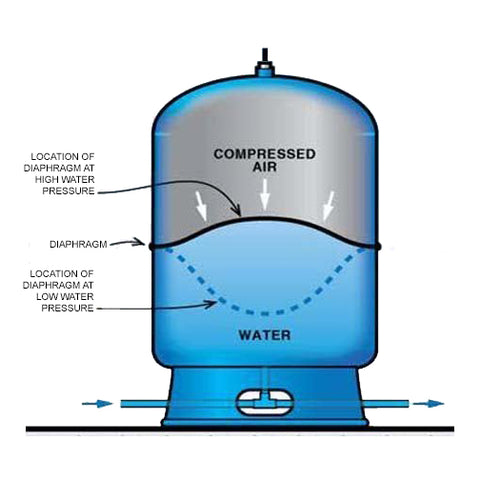

Diaphragm-Style Expansion Tanks

A diaphragm expansion tank contains a butyl rubber diaphragm attached to an internal polypropylene tank liner. Therefore, it cannot be replaced independently; the entire tank would need to be replaced if there is a problem with the diaphragm. However, the diaphragm is made of thick, high-quality rubber that will last for years.

Bell & Gossett Expansion Tank Sizing

Appropriately sized expansion tanks (bladder or diaphragm) are critical to successful air management in a hydronic system. Bell & Gossett offers the ESP Systemwize selection software for properly sizing expansion tanks and other system components. The software needs the following information to select the right tank for your system:

- Fill Temperature

- Max Temperature

- Tank Fill Pressure (The minimum pressure in psi that the tank will see during filling of the tank for start-up.)

- Max Tank Pressure (The maximum pressure in psi that the tank will see during operation in the system.)

- System Volume (in gallons)

- System Medium and Medium Mixture (if applicable)

View All Bell & Gossett ESP Systemwize Videos

Bell & Gossett Expansion Tank Installation

B&G expansion tanks are typically installed on the suction line of the hydronic hot water pump near the fill line. Another possible location, although it is used less often, is at the highest point in the system.

Connecting the expansion tank to a hydronic piping circuit near the inlet of the circulator minimizes the pressure drop between the point where the tank connects to the circuit. This location allows the differential pressure created by the circulator to be added to the static pressure in the system. Increased system pressure helps protect the circulator from cavitation and often allows for quieter operation. It also enhances the ability of air vents to eject air from the system.

Diaphragm expansion tanks should be mounted vertically with the piping connection at the top. This mounting method reduces the tank’s connection stress relative to horizontal mounting. It also prevents air in the piping from getting trapped on the water side of the expansion tank when the system is first filled.

Expansion Tanks Available from Bell & Gossett

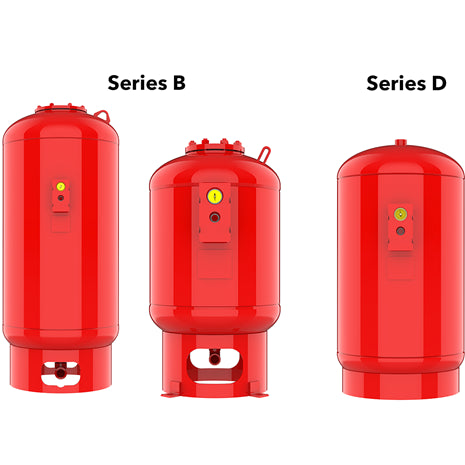

Bell & Gossett Pre-Charged Bladder & Diaphragm Expansion Tanks ASME (B,D)

Pre-charged expansion tanks contain a bladder or diaphragm to separate air charge from system water. These tanks are designed to absorb the expansion forces of heating and cooling system water while maintaining proper system pressurization under varying operating conditions.

Series B

- Designed and constructed according to ASME Section VIII, Division 1

- Heavy-duty full acceptance replaceable butyl bladder

- Sizes: 10 to 3,963 gallons

- Factory pre-charge to 12 psi, adjustable in the field

- High-pressure models up to 250 psi are available

- Seismic restraints available

- California-code sight glass available

- Integrated bladder integrity monitor included on all tanks

Shop Bell & Gossett Series B Bladder Expansion Tanks

Series D

- Designed and constructed according to ASME Section VIII, Division 1

- Economical fixed butyl diaphragm

- Sizes: 8 to 211 gallons

- Suitable for both vertical and horizontal installations

- Factory pre-charge to 12 psi, adjustable in the field

- Seismic restraints available

- California-code sight glass available

- Integrated diaphragm integrity monitor included on all tanks

Shop Bell & Gossett Diaphragm Expansion Tanks

Bell & Gossett Small Diaphragm Tanks – Non-Code (HFT)

Series HFT tanks are designed to absorb the force of heating water’s thermal expansion and maintain proper pressurization in a closed hydronic system. The heavy-duty butyl diaphragm separates system water from the air in the tank preventing water logging problems. Series HFT tanks are available for hydronic heating systems from 2 to 86 gallons.

- Prevents excessive pressure in heating systems

- Increases system performance

- Reduces oxygen corrosion

- In-line or floor mount installation

Shop Bell & Gossett Diaphragm Expansion Tanks

Bell & Gossett Series HFT Brochure

Bell & Gossett Potable Water Diaphragm Expansion Tanks – ASME (PTA)

Series PTA expansion tanks are ASME-rated, pre-charged diaphragm-type vessels designed to absorb the forces of expanding water and protect a potable water system from pressure build-up. The FDA-approved heavy-duty butyl diaphragm and polypropylene liner (sizes PTA-5 through PTA-210V) or replaceable FDA-approved full acceptance butyl bladder (sizes PTA-447 through PTA-457) completely isolates the water from the steel shell. In addition, all units include an integrated bladder integrity monitor.

- Residential and commercial applications

- Integrated bladder integrity monitor included on all models

- Controls system pressure

- Protects plumbing fixtures

- Eliminates relief valve blow-off

- FDA-approved materials

- ASME construction

- High maximum operating temperatures

- High working pressures of 175 psi and 250 psi are available

Bell & Gossett Series PTA Brochure

Bell & Gossett Potable Water Diaphragm Expansion Tanks – Non-Code (PT)

Series PT tanks for potable water systems are available from 2 to 528 gallons.

- Controls system pressure

- Protects plumbing fixtures

- Eliminates relief valve blow-off

- FDA approved materials

- High maximum operating temperatures

- High working pressures of 150 psi

Bell & Gossett Series PT Brochure

Bell & Gossett Pre-Charged Expansion Tanks for Well Water – ASME (WTA)

Series WTA expansion tanks are ASME-constructed pre-charged vessels. WTA tanks help protect pumps and pressure switches against short cycling. The well tank delivers adequate water under pressure between pump cycles to meet the required demand. It will provide economical system operation by minimizing pump starts, extending the life of the pump motor, and saving energy. The WTA tank will also assist the pump in meeting peak demand.

- Designed and constructed according to ASME Section VIII, Division 1

- Minimize pump run times, extends the life of the pump

- FDA approved materials

- High maximum operating temperatures

- 125 psi maximum working pressure

- Higher working pressures available upon request

- Integrated bladder/diaphragm integrity monitor included on all tanks

- Designed for potable well water and booster pump systems