From simple to complex, NIBCO® valves are built to last for use in commercial, industrial, and residential flow control systems. NIBCO’s extensive line of butterfly, ball, gate, circuit balancing, stop and waste valves, and Webstone® ball valves represent a history of innovation and quality engineering.

NIBCO Ball Valves

NIBCO ball valves are available in bronze, brass, lead-free, carbon steel, or stainless steel. Ball valve styles include one-piece, two-piece, three-piece, full port, or conventional port. In addition, a range of trim materials is available. Connections include press-to-connect, threaded, solder, or flanged.

Combination ball valves are an excellent choice for efficient installation and system operation. Their unique, innovative design combines commonly used components into a single product alternative that will save time and space in any facility.

NIBCO 585HP High-Performance Ball Valves

NIBCO’s 585HP high-performance lead-free bronze ball valve is the only choice for critical applications where performance matters. These valves are on the cutting edge of manufacturing technology, with incredible ease of installation and adherence to the highest quality standards.

The 585HP is the industry’s only two-piece, full-port, bronze ball valve with a 1,000-CWP pressure rating backed by a 10-year, 125% limited warranty. It features a triple-sealed stem and a patented laser-welded design.

Read more about NIBCO 585HP High-Performance Ball Valves

NIBCO Check Valves

NIBCO has a complete line-up of check valves to prevent backflow, including the NIBCO Ring Check® with a self-closing disc, horizontal swing, sliding disc, silent check, and Y-pattern.

- Wafer check valves – NIBCO wafer check valves are ideal for use in systems containing solid particles or debris as they are unlikely to clog.

- Swing check valves – NIBCO swing check valves are available in either straight or y-pattern and utilize a disc and a hinge suspended from the top of the unit using a hinge pin.

- Silent check valves – NIBCO silent check valves reduce noise for quiet operation. Silent check valves may be installed in a horizontal position or vertical patterns with flow moving up.

- Stop-check valves – NIBCO cast iron automatic steam stop-check angle valves are designed for steam systems with boilers installed in tandem.

- Lift check valves – NIBCO Ring Check in-line lift check valves feature a unique in-line, spring-assisted self-closing disc.

- Grooved check valves – NIBCO grooved check valves are typically used for fire protection applications.

- CPVC check valves – Chemtrol True Union ball-check valves from NIBCO stop the media flow in one direction while allowing flow in the opposite direction.

Read more in-depth about NIBCO Check Valves

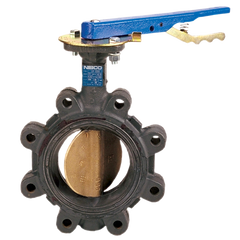

NIBCO Butterfly Valves

NIBCO butterfly valves service high-performance and fire protection systems and are available in a broad size range with wafer lug, grooved, or press end connections. Butterfly valves provide bi-directional dead-end service in commercial and industrial service and can offer many maintenance-free cycles and still accommodate “bubble tight” shut-off. NIBCO butterfly valves feature an industry-leading molded-in liner (up to 12") that virtually eliminates the potential for leaks versus a standard cartridge-style liner.

Read more in-depth about NIBCO Butterfly Valves

Shop All NIBCO Butterfly Valves

NIBCO LD-2000 Butterfly Valves

NIBCO LD-2000 butterfly valves feature a non-removable threaded collar bushing for blow-out proof positive stem retention, multiple body and stem o-ring seal styles (EPDM, Buna-N, or Fluorocarbon), and an extended neck for insulation up to 2".

The valve body of an LD-2000 fully supports its molded-in liner at flange seals and eliminates leakage between the body and liner, which may happen with a cartridge or boot-type liner. A one-piece, thru-disc style stainless steel stem provides strength, while upper and lower bushings provide smooth valve operation. A streamlined spherical disc offers high flow capacity. In addition, LD-2000 valves provide dead-end service without the need for a flange on the downstream side.

The internal stem/disc drive on NIBCO LD-2000 butterfly valves eliminates the need for pins or bolts that may create additional leak paths, turbulence in the waterway, or flow reduction. Their ductile iron body is more durable than cast iron and helps reduce breakage.

Learn more about the LD-2000 Series of NIBCO Butterfly Valves

Shop NIBCO LD-2000 Butterfly Valves

NIBCO High-Performance Butterfly Valves

High-performance butterfly valves from NIBCO are ideally suited for commercial, industrial, and mechanical HVAC services. With carbon steel bodies, stainless steel discs and stems, reinforced PTFE seats, and welded disc pins, NIBCO high-performance butterfly valves provide exceptional chemical and heat resistance.

They feature:

- Powder-coated epoxy finish

- One-piece stem

- Direct mount actuation

- Live-loaded adjustable packing with a unique flush-mounted packing gland

- Integrally cast disc-stop

- Dual offset design

- Blow-out proof stem

- Uni-directional dead-end service (arrow on the body indicates flow direction)

- Maximum operating temperature of 400°F at 100 psi

Read more in-depth about NIBCO Butterfly Valves

Shop NIBCO High-Performance Butterfly Valves

NIBCO Gate Valves

Gate valves are multi-purpose bi-directional shut-off valves for commercial and industrial applications. NIBCO gate valves are constructed of dezincification-resistant bronze and available with cast iron or ductile iron body. NIBCO gate valves feature a straight-through, unobstructed passageway, which induces minimal pressure loss over the valve. Gate valves are primarily used with larger pipe diameters (from 2" to the largest pipelines).

Read more in-depth about NIBCO Gate Valves

NIBCO Globe & Angle Valves

NIBCO globe and angle valves are constructed of bronze, cast iron, or cast ductile iron materials and offer threaded, flanged, or solder end connections. These valves are designed for throttling or regulating flow in commercial and industrial applications.

Shop All NIBCO Globe & Angle Valves

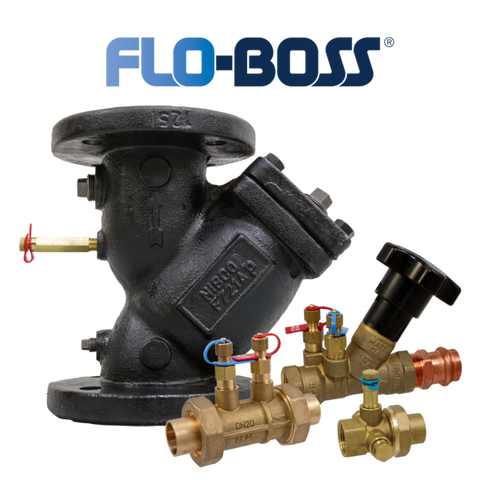

NIBCO FLO-BOSS® Balancing & Control Valves

The NIBCO FLO-BOSS line of balancing valves includes automatic, manual, lead-free, and press valves. When used with NIBCO Coil-Connect® Kits, FLO-BOSS valves are ideal for various balancing applications. All FLO-BOSS valves are quality tested to meet stringent NIBCO specifications and are backed by a five-year, 125% limited warranty.

Lead-free manual balancing valves are used in potable, non-potable, and hydronic systems. Manual balancing valves are dezincification-resistant for long-lasting, corrosion-free performance. They are available in a large selection of cast iron flanged and grooved valves. Automatic balancing valves are also dezincification-resistant and available in a wide range of flow regulation cartridges. Combination shut-off valves and unions feature a single union end design to save labor, space, and pipe joints. In addition, they are dezincification-resistant with drilled and tapped bosses. Coil-Connect pre-packaged coil kits are available for manual and automatic valves.

Download the NIBCO FLO-BOSS Catalog

NIBCO Industrial Plastic Valves

NIBCO’s Chemtrol® brand of industrial plastic valves are made from thermoplastic materials with distinctive properties for various industrial applications. Valve selections include True-Union® and Tru-Bloc® type, ball check valves, bleach ball valves, ball check valves, and butterfly valves.

NIBCO PVDF Valves

PVDF valves from NIBCO are plumbing control, pressure regulation, or delivery valves manufactured from Kynar® PVDF. PVDF (Polyvinylidene Fluoride) homopolymer is a rigid, abrasion-resistant fluorocarbon material with a design stress of 1,360 psi at 73°F and a maximum service temperature of 280°F. Types of PVDF valves available include PVDF ball valves, PVDF diaphragm valves, PVDF flow control valves, and PVDF injection valves.

Learn more about NIBCO PVDF Valves

NIBCO CPVC Valves

CPVC valves from NIBCO are ideal in commercial and industrial settings, where chemicals and high temperatures are more likely to be present. CPVC (chlorinated polyvinyl chloride) is a durable, long-lasting, and chemical-resistant building material. CPVC has a maximum operating temperature of 200°F. They are easy to install and are joined by solvent cementing or threading.

Learn more about NIBCO CPVC Valves

NIBCO Press Valves

NIBCO offers a wide range of press valves, including press ball valves, press butterfly valves, press check valves, press gate valves, press globe & angle valves, and press valve strainers.

Learn more about NIBCO Press Tools

NIBCO Valve Actuation

Electric/pneumatic actuators and control devices from NIBCO are highly efficient and reliable valve actuation options for industrial process and commercial control applications.

NIBCO Valve Strainers

Y-strainers protect equipment by filtering and straining unwanted solids in a pipeline. In addition, NIBCO offers a solid or tapped cap with a blow-off plug for screen maintenance.

NIBCO Stop & Waste Valves

Stop & waste valves from NIBCO are multi-purpose in-line shut-off valves used in low-pressure, domestic potable water systems.

NIBCO Supply Stops

Quarter-turn water supply stops from NIBCO are used in low-pressure domestic water distribution.

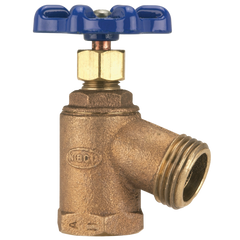

NIBCO Boiler Drain Valves

NIBCO boiler drain valves help eliminate water, sediment, and waste within a heating system. They also provide a hose end connection for external water service.

Shop NIBCO Boiler Drain Valves

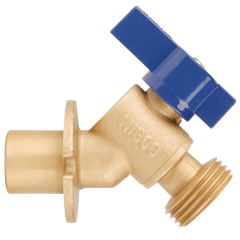

NIBCO Hose Bibbs & Sillcocks

No-kink hose bibbs from NIBCO feature a 60° angle hose spout orientation that helps prevent a garden hose from being pinched when moved to varying locations while connected to the valve.

NIBCO HydraPure® Lead-Free Bronze Valves

For over two decades, NIBCO has led the industry to develop lead-free alloys and commercialize lead-free plumbing products. NIBCO first introduced a lead-free alloy into the domestic plumbing market in 1992. NIBCO developed a line of valves produced from Performance Bronze® lead-free alloys, a family of high-quality, time-proven silicon alloys. The mechanical properties of Performance Bronze far exceed traditional plumbing alloys containing lead.

In 2009, NIBCO launched HydraPure Performance Bronze products to form a new generation of lead-free valves, fittings, and flanges that comply with changing plumbing requirements. Unsurpassed experience, research, development, testing, and production of lead-free alloys have given NIBCO the advantage of developing products with proven mechanical strength and corrosion resistance. NIBCO initially used copper-bismuth alloy C89844 in its first generation of HydraPure lead-free products. Introduced in 1992, this lead-free alloy brought NIBCO to the forefront of the industry as the first domestic producer of lead-free plumbing products. Many plumbing valve and fitting manufacturers still use similar alloys today. To overcome the technical limitations of bismuth-based alloys, NIBCO focused on developing lead-free silicon alloys with far superior mechanical properties.

NIBCO HydraPure silicon Performance Bronze exhibits mechanical properties that far exceed traditional plumbing alloys containing lead, mainly when applying temperature. Silicon improves the corrosion resistance of copper alloys, creating a largely impenetrable surface oxide barrier to corrosion attack. NIBCO uses third-party agencies to test its HydraPure silicon Performance Bronze valves for stress corrosion cracking and dezincification corrosion. NIBCO HydraPure valves have achieved the highest level of stringent testing (Commercial Hot 180°F) within the NSF/ANSI 61-8 drinking water standard. In addition, HydraPure products are listed to NSF/ANSI 372; Weighted Average Lead Content of Water Contact Components that satisfies new requirements of the Safe Drinking Water Act.

NIBCO HydraPure valves can be identified by the double oval symbol and “Si” (indicative of silicon Performance Bronze) cast in the valve’s body. Lead-free valves not manufactured from Performance Bronze include an “LF” in the body.

Download the NIBCO Lead-Free Valve Catalog

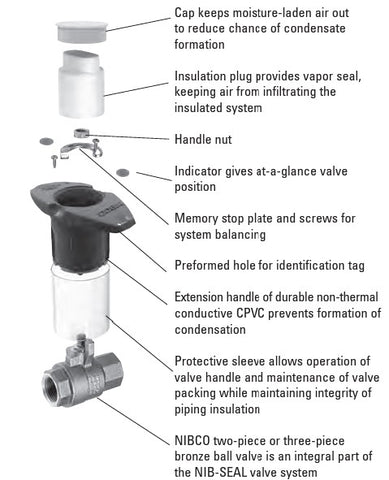

NIBCO NIB-SEAL® Handles

On Performance Bronze Threaded, Solder, and Press System Ball Valves

NIBCO bronze ball valves installed with a NIB-SEAL® insulated handle keep your insulated piping system completely intact. The revolutionary NIB-SEAL insulated handle system stops condensate and cold when used with a NIBCO bronze ball valve. Its unique thermal barrier design keeps moisture from infiltrating the insulated system while preventing thermal energy loss through exposed metal handles. Designed for new installations or retrofitting existing systems, NIB-SEAL bronze ball valves offer a wide range of advantages where insulated piping is desirable. In addition, the NIB-SEAL handle was tested to UL 2043 and is UL listed for installation in air-handling spaces (plenums).

- Protective sleeve provides a stationary surface to affix the insulation and allows the operation of the valve without destroying the integrity of the insulated system

- High-strength CPVC cylindrical handle design features easy access to standard adjustable memory stop for system balancing

- Cap and insulating plug provide a vapor seal to prevent the exchange of air, to maximize the efficiency of your insulated piping system

- Position indicators allow at-a-glance determination of whether the valve is in the open or closed position

- Preformed hole allows for convenient tagging

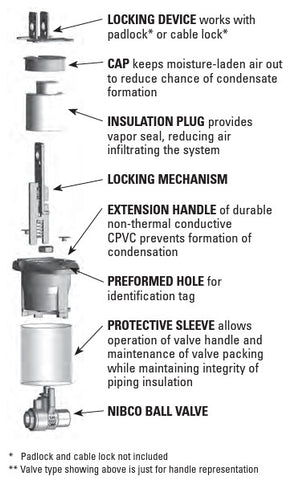

NIB-SEAL Locking Handle

The patented technology of the 3-in-1 NIB-SEAL locking handle solves three problems: it extends, insulates, and locks. The innovative locking handle design extends valve actuation to provide ample room for protecting around piping systems, and its unique thermal barrier system prevents heat transfer and condensate development. The NIB-SEAL locking handle also allows the valve to be locked in the fully open or closed position to avoid accidental actuation. The NIB-SEAL locking handle is designed for new installations and engineered to work with NIBCO bronze ball valves.

NIB-SEAL locking handles are approved for piping systems requiring up to 2" insulation; specify a non-conductive CPVC extended-locking handle bronze ball valve tested to UL 2043 and UL listed for installation in air handling spaces. The assembly offers a vapor seal, position indicators, a locking device, and actuation without disturbing the insulation. Designed for new installations, the NIB-SEAL locking handle installed on bronze ball valves offers a wide range of advantages for typical commercial HVAC systems and industrial applications where insulated piping with a locking device is desirable. Specify NIB-SEAL insulated locking handle.

Shop NIBCO Valves with the NIB-SEAL Handle Option

NIBCO Valve Replacement Parts & Accessories

A complete line of replacement parts and accessories, such as hoses, air vents, extensions, PT ports, and metering stations, are available for NIBCO valves.

Webstone Valves

Webstone, a brand of NIBCO, has been an industry-leading manufacturer of residential and commercial valves used in plumbing, hydronic, radiant, solar, and geothermal applications since 1954.

Webstone valves include:

- Ball valves

- Check valves

- Control valves

- Globe valves

- Mixing valves

- and more

Read more about Webstone Valves

NIBCO Valve FAQs

Where to buy NIBCO valves?

NIBCO valves are available nationwide through multiple distribution channels. Liberty Supply is proud to provide our customers access to the full line of NIBCO products. Whether you need a small valve for a residential application or a large-diameter industrial valve, Liberty Supply has a direct relationship with NIBCO to get the valve you need.

Contact a Sales Representative Today

Where are NIBCO/Webstone valves made?

NIBCO is a leading manufacturer and distributor of high-quality equipment in the United States. With 13 manufacturing plants and nine distribution centers, the company can meet the demands of its customers globally. Domestic locations include Indiana, Texas, Arkansas, Massachusetts, Virginia, and Georgia. With Mexico and Poland being their international locations. Bronze valves and fittings are manufactured in Reynosa, Mexico, along with lead-free and press ball valves. CPVC pipe systems are manufactured at Poland’s sales and marketing center.

Which flux to use with NIBCO lead-free valves?

The purpose of flux is to clean, prep, and protect the surfaces of the joint to accept the solder. The flux must have an active temperature range compatible with the intended solder. Many plumbing flux and solder combinations have been confirmed for use with silicon bronze alloys. There are generally many flux types beyond plumbing – best practice calls for installers to utilize plumbing paste fluxes containing chlorides. Contact the flux manufacturer regarding the suitability of their flux for use with any intended solder. Confirming flux suitability per the local plumbing code is the installer’s responsibility.

How to install a NIBCO lead-free valve?

First, ensure proper joint preparation for the solder cup and mating tube. Proper joint preparation is critical to achieving a good solder joint – follow all best practices for prepping the tube by using coarse emery cloth or a clean wire brush, including square cutting, de-burring (inside and outside), cleaning, etc.

Next, select the appropriate solder, flux, and heat. Choosing a compatible solder/flux combination is a critical first step to achieving a quality joint.

- Solder: NIBCO recommends plumbing solders with a melting point above 400°F. Solder with a melting point above 400°F include traditional 95/5 tin/antimony and those containing silver or other filler elements.

- Flux: The purpose of flux is to clean, prep, and protect the surfaces of the joint to accept the solder. The flux must have an active temperature range compatible with the intended solder. Many plumbing flux and solder combinations have been confirmed for use with silicon bronze alloys. There are generally many flux types beyond plumbing – best practice calls for installers to utilize plumbing paste fluxes containing chlorides. Contact the flux manufacturer regarding the suitability of their flux for use with any intended solder. Confirming flux suitability per the local plumbing code is the installer’s responsibility.

- Heat: Silicon bronze alloys will transfer heat away from the heat-affected area more slowly than copper or leaded bronze; therefore, more attention may be required to achieve uniform heating of the alloy. Select the torch tip and gas mix to distribute the heat adequately. The hotter the flame, the more skill, and technique are required.

- Begin by mildly preheating the socket and tube.

- Do not direct the flame into the gap.

- Heat the entire joint, and always keep the flame moving – do not linger in any one position.

- Watch for the flux to activate per the flux manufacturer’s recommendation. The flux will generally bubble as it reaches activation temperature, taking care not to burn out the flux.

- Apply the flame to the base of the solder cup – the farthest point you want to draw the solder to.

- With uniform heating around the base of the cup, touch the solder to the joint. If the solder doesn’t melt, remove the solder and continue heating the entire joint.

- When the solder begins to melt, return the flame to the base of the cup, rotating the flame 360° around the cup. Due to the expansion and contraction of materials after heating, the ball valve or gate valve pack nut may need to be tightened.

BRAZING RECOMMENDATIONS: Lead-free silicon bronze alloy brazing, including filler material selection and installation, is identical to that used in good industry practice for traditional plumbing products.

THREADING RECOMMENDATIONS: When threading pipe, gauge pipe threads for size and length to avoid jamming the pipe against the seat or disc. Thoroughly clean the threaded end to remove excess material shavings. For a good joint, use PTFE tape or pipe dope. If pipe dope is used, apply sparingly on pipe threads, NEVER on valve threads. Do not allow pipe dope into the valve body to avoid damage to the disc, ball, or seat—close the valve completely before installation. Apply wrench to hex next to the pipe and guard against possible distortion.